Feature

Achieves outstanding cost efficiency and defect-free production

Offers the high speed of 52,000 CPH, and multiple capabilities to handle components from 0201 to 100 x 55 mm

Outstanding cost performance: Value-added production with mounting capability, typically not achievable within the economy price range

Achieves high-quality production: Toward defect-free production with high mounting accuracy and a wide range of functions

Easy-to-use, multi-purpose operation: Simple, single-head operation bringing great usability

High-speed multi-purpose in-line head: Achieves high-speed mounting of 52,000 CPH (under our optimized conditions). Also secures an accuracy of ± 35 μm (Cpk ≧ 1.0).

Scan camera: The head side features a component-recognition camera to identify components during transportation. Shortest-route transportation from pickup to mounting, improving productivity.

High-quality production

Detects posture anomalies of components before mounting: The side-view function detects pickup status and component presence with no time loss, for defect-free production.

Prevents defects from bended leads: Coplanarity checker detects IC’s bended lead before mounting, preventing defects.

Accurately detects BGA ball missing: Side lighting meticulously detects missing BGA balls that cannot be detected with lighting from underneath.

Achieves steady pickup and mounting: The head can change speed momentarily during pickup and mounting to maintain production and steady quality.

Great usability

Slim and light feeder improves operability: Compact feeder weighing under 1 kg, operable with one hand for better work efficiency.

Components can be supplied “anytime” with “no specific skills”: Remaining components monitor and Auto Loading Feeder are combined to supply components efficiently at any chosen timing, optimizing operators’ component-supply work.

Efficiently supplies tray components: YRM10 can feature the space-saving, cost-effective 15-magazine tray component feeder sATS15R.

Nozzle is automatically replaced, requiring no changeovers: The nozzle is automatically replaced according to the mounting PCB. The nozzle holder can be detached with just one touch, providing ease of maintenance and changeovers.

Detail Image

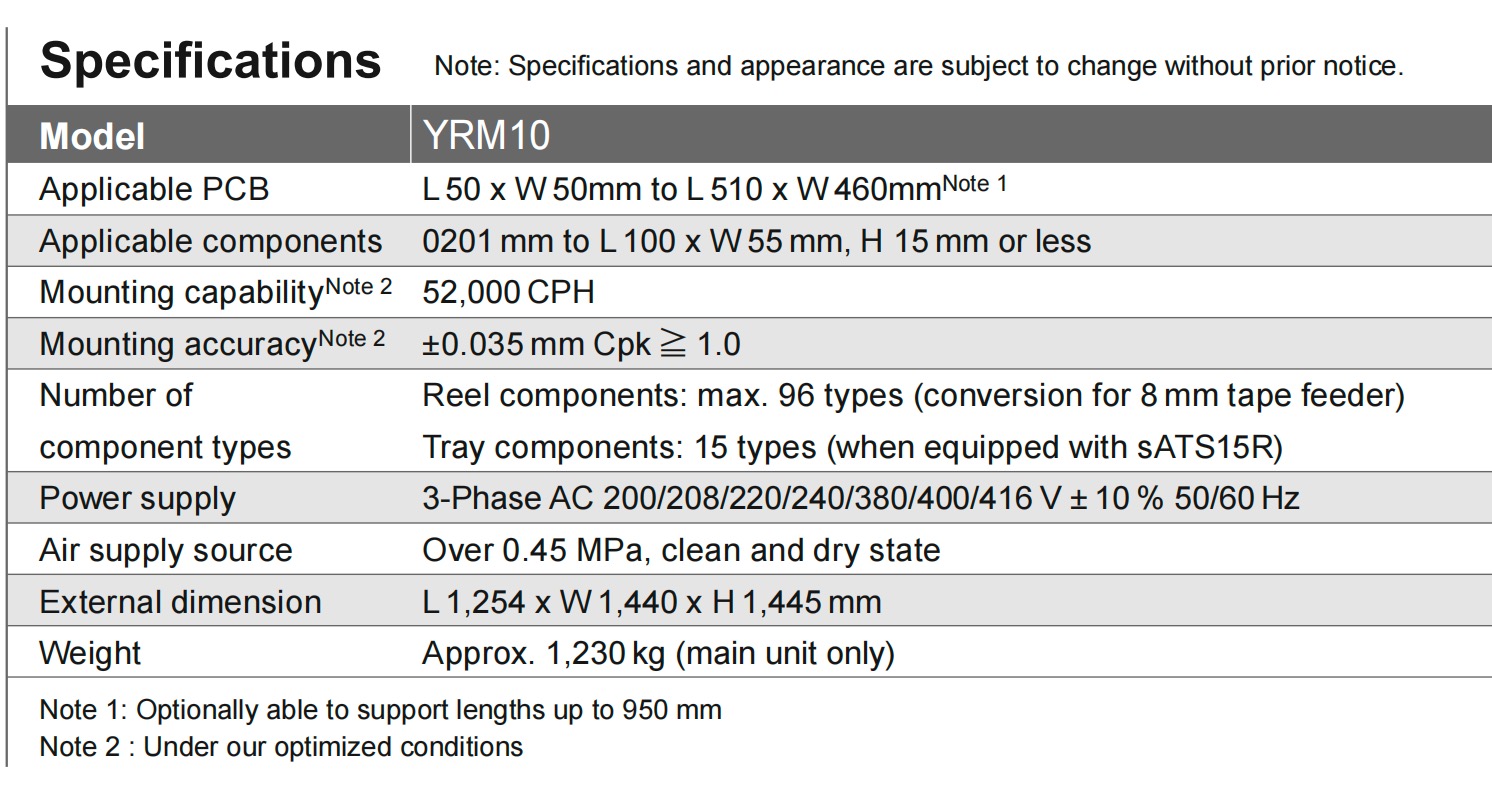

Specifications