Feature

●The high-pressure spray system is specially used for water-based cleaning liquid to clean the screen, misprinted plate, printing machine scraper and other processes.

●Double liquid tank, equipped with heating system, to meet the needs of cleaning, rinsing and hot air drying.

●Process flow: cleaning - chemical isolation - rough rinsing (open/closed loop) - fine rinsing (open/closed loop) - drying.

●Preparation of advanced fully automatic touch screen operation software, program files are saved, and the use is extremely simple.

●System counting function, which can automatically accumulate the number of cleaning stencils and the number of circulating filtration times.

●The pressure of liquid and pump can be displayed through the panel pressure gauge, and the operation status of the equipment can be fed back in time.

●The spray pressure is monitored by a pressure sensor, and an alarm will be given if the pressure exceeds the set pressure range.

●The liquid returns directly to reduce the consumption of liquid

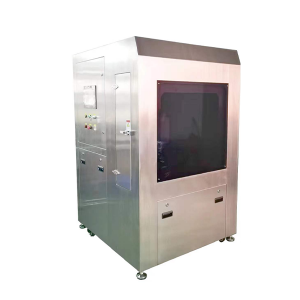

●The overall stainless steel body is sturdy and durable, resistant to acid, alkali and other cleaning fluids. the

●High-pressure blower + hot air drying, the drying effect is more rapid and thorough.

●Lower operating costs, only 50-200ml of liquid is needed for each cleaning, and compressed air is used to recover the remaining liquid in the pipeline and pump after cleaning, which can reduce liquid consumption by 50%.

Function:

1. The cleaning method of the equipment: left and right mobile double-sided equal pressure liquid injection, the mechanism adopts optical axis module, high-precision ball screw, driven by stepping motor to make power left and right reciprocating motion, to ensure accurate reset every time and long life , easy to maintain or replace, run the spray bar reciprocating left and right to spray, you can choose a local area to achieve targeted spraying, and the tension of the steel mesh will not be affected after cleaning.

2. Solder paste impurities are separated in an orderly manner, and the use of fiber adsorption and filtration effects makes maintenance more convenient.

3. Visualization, the whole cleaning process, touch screen operation is more convenient, program memory function.

4. The machine is composed of cleaning system, cutting system, rinsing system, drying system and filtering system. The machine uses electricity and gas as energy sources, manually puts the stencil into the cleaning room, after setting the cleaning, rinsing, drying and other related parameters on the touch screen, press the start button, the stencil will be automatically cleaned, rinsed and dried . When the set cleaning process is over, it will automatically stop running and reset to realize the next working process. The software function of the machine is very powerful, which can save the specific information of cleaning the screen (time, frequency, cutting time, frequency, rinsing time, frequency, drying temperature time, frequency, etc.) of the cleaning screen. The machine is very convenient for the operator to clean Stencil, first mate to improve production efficiency and quality. It is a new type of high-performance automatic cleaning equipment. The equipment uses water-based liquid or DI water as cleaning agent, without any safety hazard and no harm to personnel.

5. Hot air drying: The high-pressure fan enters the air knife through the heating box to dry the cleaned parts quickly.

Detail Image

Specifications

|

Model |

TY-ES750 |

|

Machine Dimension |

1220mm(L) *1120mm(W) *1850mm(H) |

|

Machine Weight |

580KG |

|

Stencil Size |

Max 750*750*40mm |

|

Cleaning Quantity |

1pc |

|

Spray Pressure |

2-3KG (total pressure value) |

|

Maximum volume of liquid tank |

50L*2PCS |

|

Optimal Liquid Usage |

40L*2PCS |

|

Minimum working solution volume |

20L*2PCS |

|

Number of pumps |

3pcs (1 solvent pump, 1 rinse pump, 1 drain pump) |

|

Control/Operating System |

Mitsubishi PLC + China Taiwan Weilun touch screen |

|

Cleaning System |

Independent electric high-pressure pump to extract solvent + left and right movable double-sided isobaric nozzle nozzle high-pressure spray cleaning (Independent pump can effectively avoid liquid channeling and reduce the working frequency of the pump to extend the frequency of use) |

|

Return system |

Set the reflux time to 40-60 seconds (fully let the cleaning agent return to the solvent tank to save potion) |

|

Rinse system |

Independent electric high-pressure pump to extract rinsing water + left and right movable double-sided isobaric nozzle nozzle high-pressure spray cleaning (Independent pump can effectively avoid liquid channeling and reduce the working frequency of the pump to extend the frequency of use) |

|

Drying system |

Heating box heating + blower hot air backflow + left and right moving wind shear |

|

Filtering system |

Tertiary filtration Level 1 Filtration: Filter impurities and labels 2-stage filtration: filter solder paste and rosin particles 3-stage filtration: 1μm particles such as solder paste, rosin, red glue and pollutants |

|

Cleaning Principle |

High pressure spray cleaning + rinsing |

|

Cleaning Method |

The electric diaphragm pump extracts the cleaning agent after filtration, and sprays the spray head in a fan-shaped water column on the left-right movable double-sided isobaric spray bar to clean the steel mesh and scraper, and remove solder paste, red glue, ink, resin and other dirt Clear, then rinse in the same way |

|

Equipment Fixtures |

Equipped with special fixed casters |

|

Equipment material |

304 stainless steel material (thickness 1.5mm) |

|

Equipment pipe material |

PPH material (Long life, high temperature resistance, strong acid and alkali resistance, no scaling, easy to replace, etc.) |

|

Applicable cleaning fluid |

water-based cleaner |

|

Single cycle loss/sheet |

<200ml Depending on the size, quantity, cleaning time, and heating temperature of the cleaning product |

|

Input power |

AC380V 50HZ 50A |

|

Total power |

25KW |

|

Input air pressure |

0.4-0.6MPa |

|

Air flow volume |

200 L/min @ Cleaning (consumed during cleaning)600L/Min @ Drying (drying air cut consumption) |

|

Exhaust Velocity Requirements |

7.5m³/min, just install Φ125 exhaust pipe |

|

Pipeline |

Three pumps and three pipes (Independent pump can effectively avoid liquid channeling and reduce the working frequency of the pump to extend the frequency of use) |

|

Drying method |

Air knife cutting water + hot air drying (Improve drying effect and reduce drying time) |

|

Drying principle |

Heating tube heating, hot air backflow, left and right moving double side wind cutting. |

|

Drying temperature |

room temperature -60° (After repeated tests, exceeding 60° will damage the screen frame glue, and the upper limit of the program is 60° to avoid damage to the screen frame caused by improper operation) |

|

Number of nozzles |

22pcs |

|

Number of cleaning tanks |

1pc |

|

Number of rinse tanks |

1pc |

|

Closing method of cleaning tank |

The first layer: steel door seal The second layer: It is sealed with an anti-corrosion sealing ring, and the imported safety valve is closed to effectively protect the safety of the operator and the product. |

|

Cleaning ability |

Solder paste, red glue, and ink can be completely cleaned |

|

Wash + Dry Time |

Solvent cleaning: 2-5 minutes (for reference only) Rinse: 1-3 minutes (for reference only) Drying: 2-5 minutes (for reference only) 1-999S cleaning and drying time can be set separately |

|

Cleaning fluid replacement method |

Equipped with special pipeline for automatic extraction |

|

Cleaning solution treatment method |

Equipped with special pipeline for automatic extraction |

|

Viewport |

Yes (cleaning room is equipped with LED lighting for easy observation of cleaning effect) |

|

Operation panel |

Touch screen, buttons, emergency stop, start key, reset key |

|

Is it used in COB stencil cleaning |

YES |

|

Consumables |

Water-based cleaning agent, filter element |

|

Maintenance items, frequency and time-consuming |

1. Filter element replacement: 1 month (replacement takes 5 minutes) 2. Replacement of solvent: 3 months (replacement takes 30 minutes) 3. Sprinkler head cleaning: 6 months (cleaning takes 10 minutes) The above is for reference only, and can be selectively replaced according to the cleaning frequency of the product. |