Feature

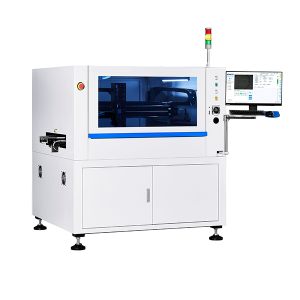

1.GKG-G9+ automatic solder paste printing machine is a new product aimed at high-end SMT applications, which can perfectly meet the process requirements of 03015, 0.25pich and other fine pitch, high precision and high speed.

2.CCD digital camera system: Brand-new optical path system-uniform ring light and high-brightness coaxial light, together with the brightness function that can be adjusted steplessly, makes all types of Mark points can be well recognized (including uneven Mark points) and is suitable for plating Tin, copper plating, gold plating, HASL, FPC and other types of PCBs with different colors.

3.High-precision PCB thickness adjustment jacking platform: The structure is compact and reliable, the lifting is stable, and the height of the PIN needle is automatically adjusted by software, which can realize the adjustment of the position and height of PCB boards with different thicknesses.

4.Rail positioning system: Utility model invention patent. The detachable and programmable flexible side clamping device can flatten the top of the soft board and warped PCB. Through software programming, it can automatically expand and contract without affecting the tin thickness.

5.Brand new scraper structure design: Through the new scraper structure of the slide rail and the cylinder, the operation stability is improved and the service life is extended.

6.High-speed stencil cleaning: The dripping cleaning structure effectively prevents the cleaning from being unclean due to local lack of solvent caused by the plugging of the solvent pipe.

7.New multi-function interface: Concise and clear, easy to operate. Real-time temperature remote control function.

Detail Image

Specifications

| Machine performance | |

| Repeat position accuracy | ±10um@6 σ , CPK≥2.0 |

| Print accuracy | ±18um@6 σ , CPK≥2.0 |

| NCP-CT | 7s |

| HCP-CT | 18s/pcs |

| Process CT | 4min |

| Change line CT | 2min |

| Substrate processing parameter | |

| Max board size | 450*340mm |

| Min board size | 50*50mm |

| Board thickness | 0.4~6mm |

| Camera mechanical range | 450*340mm |

| Max board weight | 3kg |

| Board adge clearance | 2.5mm |

| Board height | 15mm |

| Transport speed | 900±40mm |

| (Max) Transport speed | 1500mm/s max |

| Transport direction | One stage |

| Transmission direction | Left to right |

| Right to left | |

| In and out the same | |

| Support system | Magnetic pn |

| Support block | |

| Manual up-down table | |

| Board damp | Automatic top clamping |

| Side clamping | |

| Adsorption function | |

| Printing parameters | |

| Print speed | 10-200mm/s |

| Printing pressure | 0.5~10kg |

| Print mode | One/twice |

| Queegee type | Rubber, squeegee blade (angle 45/55/60) |

| Snap- off | 0-20mm |

| Sanp speed | 0-20mm/s |

| The template frame size | 470*370mm-737*737mm (thickness 20-40mm) |

| Positioning mode of steel mesh | Automatic Y-direction positioning |

| Cleaning parameteres | |

| Cleaning system | Dry, wet, vaccum, three modes |

| High speed cleaning | Integrated & weave cleaning |

| Cleaning system | Side spray type |

| Cleaning stroke | Automatic generation |

| Cleaning position | Pre cleaning |

| Cleaning speed | 10-200mm/s |

| Cleaning fluid consumption | Auto/Manually adjustable |

| Cleaning pater consumption | Auto/Manually adjustable |

| Vision parameters | |

| CCD FOV | 10*8mm |

| Camera type | 130 thousand CCD digital camera |

| Camera system | Lock up/down optic structure |

| Camera cycle time | 100ms |

| Fiducial mark types | Standard fiducial mark shape |

| Round, square, diamond, cross | |

| Pad and profile | |

| Mark size | 0.1-6mm |

| Mark number | Max. 4pcs |

| Stay away number | Max. 1pc |

| Machine parameter | |

| Power source | AC 220 ±10%, 50/60Hz 2.2KW |

| Air pressure | 4~6kgf/cm² |

| Air consumption | ~5L/min |

| Operating temperature | -20°C~+45°C |

| Working invironment humidity | 30%-60% |

| Machine dimension (without flower light) | 1172(L)*1385(W)*1530(H)mm |

| Machine weight | Appr 1000kg |

| Equipment load bearing requirements | 650kg/m² |