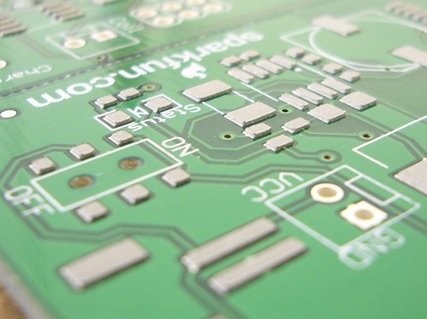

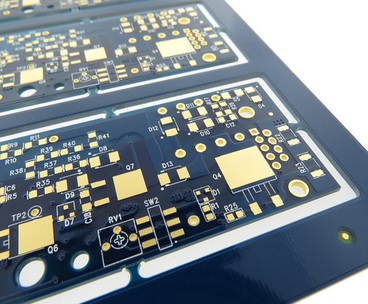

Reflow soldering ita ce hanyar da aka fi amfani da ita don haɗa abubuwan da ke kan dutsen saman zuwa allon da'ira (PCBs).Manufar wannan tsari ita ce samar da haɗin gwiwa mai karɓuwa ta hanyar fara dumama abubuwan da aka gyara / PCB / manna mai siyarwa sannan kuma a narkar da mai siyarwar ba tare da haifar da lalacewa ta hanyar zafi ba.

Mahimman abubuwan da ke haifar da ingantaccen tsarin siyarwar sake kwarara sune kamar haka:

- Na'ura mai dacewa

- Bayanan martaba na sake kwarara karɓuwa

- PCB/bangaren sawun Zane

- An buga PCB a hankali ta amfani da stencil da aka ƙera

- Maimaituwar jeri na abubuwan hawan saman saman

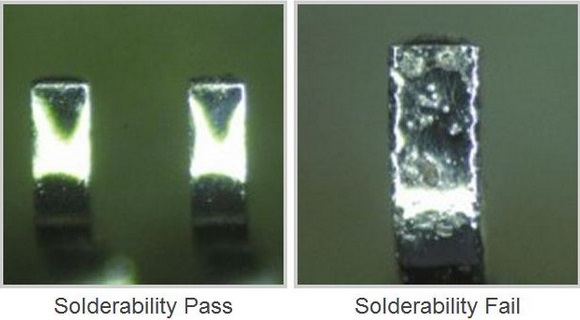

- PCB mai inganci, abubuwan da aka gyara da manna solder

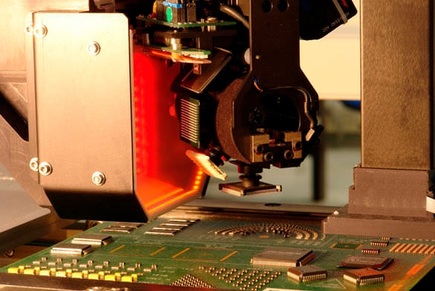

Injin da ya dace

Akwai nau'ikan nau'ikan na'ura mai sake jujjuyawa da ake samu dangane da saurin layin da ake buƙata da ƙira/kayan aikin tarukan PCB da za a sarrafa.Wurin da aka zaɓa ya buƙaci ya zama girman da ya dace don ɗaukar nauyin samar da kayan aiki da kayan aiki.

Ana iya lissafin saurin layin kamar yadda aka nuna a kasa:-

Gudun layi (mafi ƙarancin) =Alloli a minti daya x Tsawon kowane allo

Factor Load (sarari tsakanin alluna)

Yana da mahimmanci a yi la'akari da maimaitawar tsarin don haka 'Load Factor' yawanci ana ƙayyade ta masana'anta na injin, lissafin da aka nuna a ƙasa:

Don samun damar zaɓar madaidaicin girman reflow tanda gudun aiwatar (akayyade a ƙasa) dole ne ya zama mafi girma fiye da mafi ƙarancin saurin layin da aka ƙididdige.

Gudun tsari =Tanda dakin mai zafi tsawon

Tsawon lokacin zama

A ƙasa akwai misalin lissafi don kafa daidai girman tanderu:-

Mai tarawa na SMT yana son samar da allunan inch 8 akan ƙimar 180 a kowace awa.Mai sana'ar manna solder yana ba da shawarar minti 4, bayanin martaba mataki uku.Har yaushe zan buƙaci tanda don sarrafa allo a wannan kayan aikin?

Alloli a minti daya = 3 (180 / awa)

Tsawon kowane allo = 8 inci

Factor Load = 0.8 (2-inch sarari tsakanin alluna)

Lokacin Zauren Tsari = Minti 4

Ƙididdigar Gudun Layi:(3 alluna/min) x (8 inci/ allo)

0.8

Gudun layi = 30 inci / minti

Don haka, tanda mai sake gudana dole ne ta sami saurin aiwatarwa na akalla inci 30 a cikin minti daya.

Ƙayyade tsayin ɗakin murhu mai zafi tare da daidaita saurin tsari:

30 in/min =Tanda dakin mai zafi tsawon

Minti 4

Tsawon tanda = 120 inci (ƙafa 10)

Lura cewa tsayin tanda gabaɗaya zai wuce ƙafa 10 gami da sashin sanyaya da sassan ɗaukar kaya.Lissafin shine don TSAWA MAI DUMI - BA GWAMNATIN TANA BA.

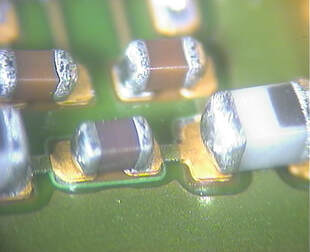

1. Nau'in jigilar kaya - Yana yiwuwa a zaɓi na'ura mai jigilar raga amma gabaɗaya an ƙayyade na'urorin jigilar gefe don ba da damar tanda ta yi aiki a cikin layi da kuma iya aiwatar da taruka masu gefe biyu.Baya ga na'ura mai ba da hanya ta gefe ana yawan haɗa goyon bayan allo na tsakiya don dakatar da PCB daga raguwa yayin aikin sake kwarara - duba ƙasa.Lokacin sarrafa majalisu masu gefe biyu ta amfani da tsarin jigilar kaya dole ne a kula don kar a dame abubuwan da ke ƙasa.

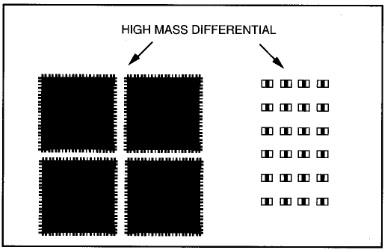

2. Rufe madaidaicin madaidaicin don saurin magoya bayan convection - Akwai wasu fakitin hawa sama kamar SOD323 (duba sakawa) waɗanda ke da ƙaramin yanki na lamba zuwa rabo mai yawa waɗanda ke da saurin damuwa yayin aikin sake kwarara.Kulawar saurin madauki na masu sha'awar taron shine zaɓin da aka ba da shawarar don taro ta amfani da irin waɗannan sassa.

3. Ikon atomatik na na'ura mai ɗaukar hoto da faɗin allon tallafi na tsakiya - Wasu injina suna da daidaitaccen nisa na hannu amma idan akwai majalisu daban-daban da za a sarrafa su tare da bambance-bambancen nisa na PCB to ana ba da shawarar wannan zaɓi don kiyaye daidaitaccen tsari.

Bayanin Maimaitawa Mai karɓuwa

- Nau'in solder manna

- PCB abu

- PCB kauri

- Adadin yadudduka

- Adadin jan ƙarfe a cikin PCB

- Adadin abubuwan hawan saman ƙasa

- Nau'in abubuwan hawan saman saman

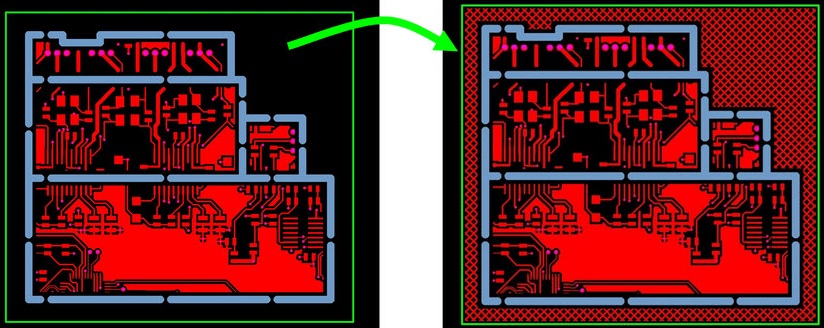

Domin ƙirƙirar reflow profile thermocouples an haɗa su zuwa wani samfurin taro (yawanci tare da babban zafin jiki solder) a da dama wurare don auna kewayon yanayin zafi a fadin PCB.Ana ba da shawarar samun aƙalla thermocouple ɗaya wanda ke kan kushin zuwa gefen PCB da thermocouple ɗaya wanda ke kan kushin zuwa tsakiyar PCB.Ya kamata a yi amfani da ƙarin ma'aunin zafi da sanyio don auna cikakken yanayin zafi a cikin PCB - wanda aka sani da 'Delta T'.

A cikin bayanin martaba na sake kwarara na yau da kullun akwai matakai huɗu - Preheat, jiƙa, sake kwarara da sanyaya.Babban manufar shine don canja wurin isasshen zafi a cikin taron don narke mai siyar da samar da haɗin gwiwar solder ba tare da haifar da lahani ga abubuwan da aka gyara ko PCB ba.

Yi zafi- A wannan lokacin abubuwan da aka gyara, PCB da solder duk suna mai zafi zuwa ƙayyadadden jiƙa ko yawan zafin jiki suna mai da hankali don kada suyi zafi da sauri (yawanci bai wuce 2ºC/daƙiƙa ba - duba takardar bayanan solder).Dumama da sauri na iya haifar da lahani kamar abubuwan haɗin gwiwa don tsattsage da manna solder zuwa fantsama yana haifar da ƙwallayen siyar yayin sake fitowa.

Jiƙa- Manufar wannan lokaci shine don tabbatar da duk abubuwan da aka gyara sun kasance har zuwa yanayin da ake buƙata kafin shiga matakin sake gudana.Jiƙa yawanci yana ɗaukar tsakanin daƙiƙa 60 zuwa 120 dangane da 'banbancin taro' na taron da nau'ikan abubuwan da ke akwai.Mafi kyawun canja wurin zafi yayin lokacin jiƙa ana buƙatar ɗan lokaci kaɗan.

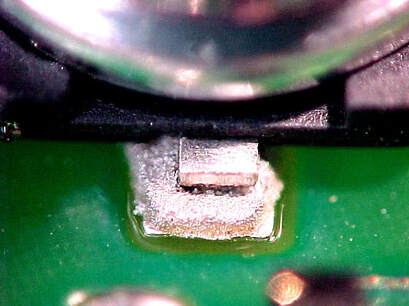

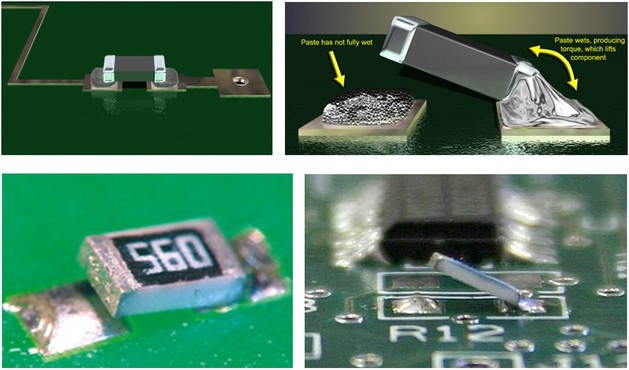

Wani lahani na yau da kullun bayan sake dawowa shine samuwar ƙwallayen siyar da guntu na tsakiya kamar yadda ake iya gani a ƙasa.Maganin wannan lahani shine canza ƙirar stencil -Ana iya ganin ƙarin cikakkun bayanai a nan.

Sanyi- Wannan shi ne kawai matakin lokacin da aka sanyaya taron amma yana da mahimmanci don kada ya kwantar da taro da sauri - yawanci yawan shawarar da aka ba da shawarar kada ya wuce 3ºC / na biyu.

PCB/Kamfanin Ƙwararren Ƙwararren Ƙwallon ƙafa

An buga PCB a hankali ta amfani da stencil da aka ƙera

Maimaituwar jeri na abubuwan hawan saman saman

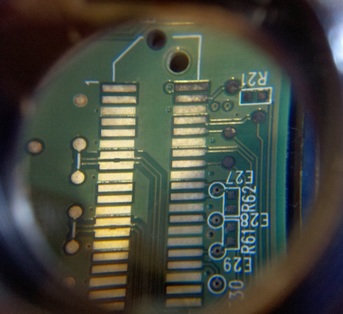

Ana iya ƙirƙirar shirye-shiryen jeri na ɓangaren ta amfani da na'urori masu ɗauka da wuri amma wannan tsari bai yi daidai ba kamar ɗaukar bayanan centroid kai tsaye daga bayanan PCB Gerber.Sau da yawa ana fitar da wannan bayanan centroid daga software na ƙirar PCB amma wani lokaci ba ya samuwa don hakaSabis don samar da fayil na centroid daga bayanan Gerber ana bayarwa ta Tsarin Dutsen Surface.

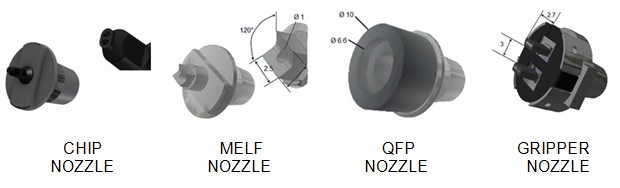

Dukkanin injunan sanyawa kayan aikin zasu sami 'Aikin Matsayi' da aka kayyade kamar: -

35um (QFPs) zuwa 60um (chips) @ 3 sigma

Hakanan yana da mahimmanci don zaɓar madaidaicin bututun ƙarfe don nau'in kayan aikin da za a sanya - ana iya ganin kewayon nozzles daban-daban na abubuwan sanyawa a ƙasa: -

PCB mai inganci, abubuwan da aka gyara da manna solder

Lokacin aikawa: Juni-14-2022