Feature

Super-high-speed rotary RM head achieves 120,000cph

Rotary head boosts mountability of tiny components. This maintains high-speed production since head replacements are no longer needed. This technology helps carry on the 1-head solution concept. This head can handle components ranging from super tiny 0201 mm components up to medium-sized odd-shaped components of 12 x 12 mm dimensions with heights of 6.5 mm.

High-speed multi-purpose inline HM head

The flexible “all-round” head not only has high-speed, but also has the versatility essential for mounting super-tiny 0201 mm components all the way up to large-size components of 55 x 100 mm and heights up to 15 mm.

Odd-shaped components capable inline FM head

The ultra-wide-range head fully handles components ranging from super-tiny 03015 mm chips on up to ultra-large components of 55 x 100 mm and heights of 30 mm. Force control is also available.

Feature 2: Solution for variable-mix, variable-volume production

Takes on various types of production with superhigh efficiency

Ensures super-high efficiency for production of various types, by combining parallel mounting and alternate mounting, and 4-stage mounting with the newly developed dual-lane conveyor. Achieves high productivity even when production type varies by lane.

W330 mm dual-lane

Produces large size PCBs of up to L810 × W330 mm in dual-lane. Can increase PCBs to be picked up and carriers transported, raising production efficiency.

Automatic push-up pin exchange system

This automatically positions the push-up pins. Using along with the automatic program changeover function drastically reduces the workload during production changeovers.

Auto nozzle station

The nozzle is automatically exchanged for efficient production. The nozzle holder can be exchanged with a single touch, which makes setup and maintenance easy.

Feature 3: High-accuracy mounting and steady production of micro components

High-accuracy mounting level of ±15 μm (Cpk≥1.0)

Machine vibration controlled with a very rigid base and adjustment accuracy improved with Head Code Max, achieving a highaccuracy mounting level of ±15 μm.

Low-impact mounting

Relative height of the mounting surface and component bottom controlled by measuring PCB height to control mounting height, which minimizes impact on micro components together with a low static-loaded nozzle.

Steady pick-up and mounting

Multiple Accuracy Compensation System “MACS” realizes stable pick-up and mounting by recognizing correction marks in the machine during production.

Feature 4: High-efficiency production with various features

Non-stop tray feeder eATS30

High-capacity tray feeder that can store up to 30 pallets. Provides a non-stop supply of tray components, achieving non-stop production. The lineup also includes a 10-stage tray component feeder “cATS10R”, with excellent space savings and cost performance.

Nozzle and feeder maintenance warnings

Self-diagnosis and selfrecovery functions continuously maintain nozzles and feeders in a clean state for continuous high-quality production.

Auto-loading feeder

A simple task of cutting and inserting a tape reduces the load in the component supply work. Setting two reels makes it possible to level off the component supply timing, minimizing the risk of line stoppage due to failure

of component supply.

Vision system further enhancing component mounting quality

The side-view camera improves quality for mounting of tiny components. Coplanarity checker can also be installed as an option. All ImageTracer (option) saves every component recognition image, providing strong support

for analysis of the mounting quality.

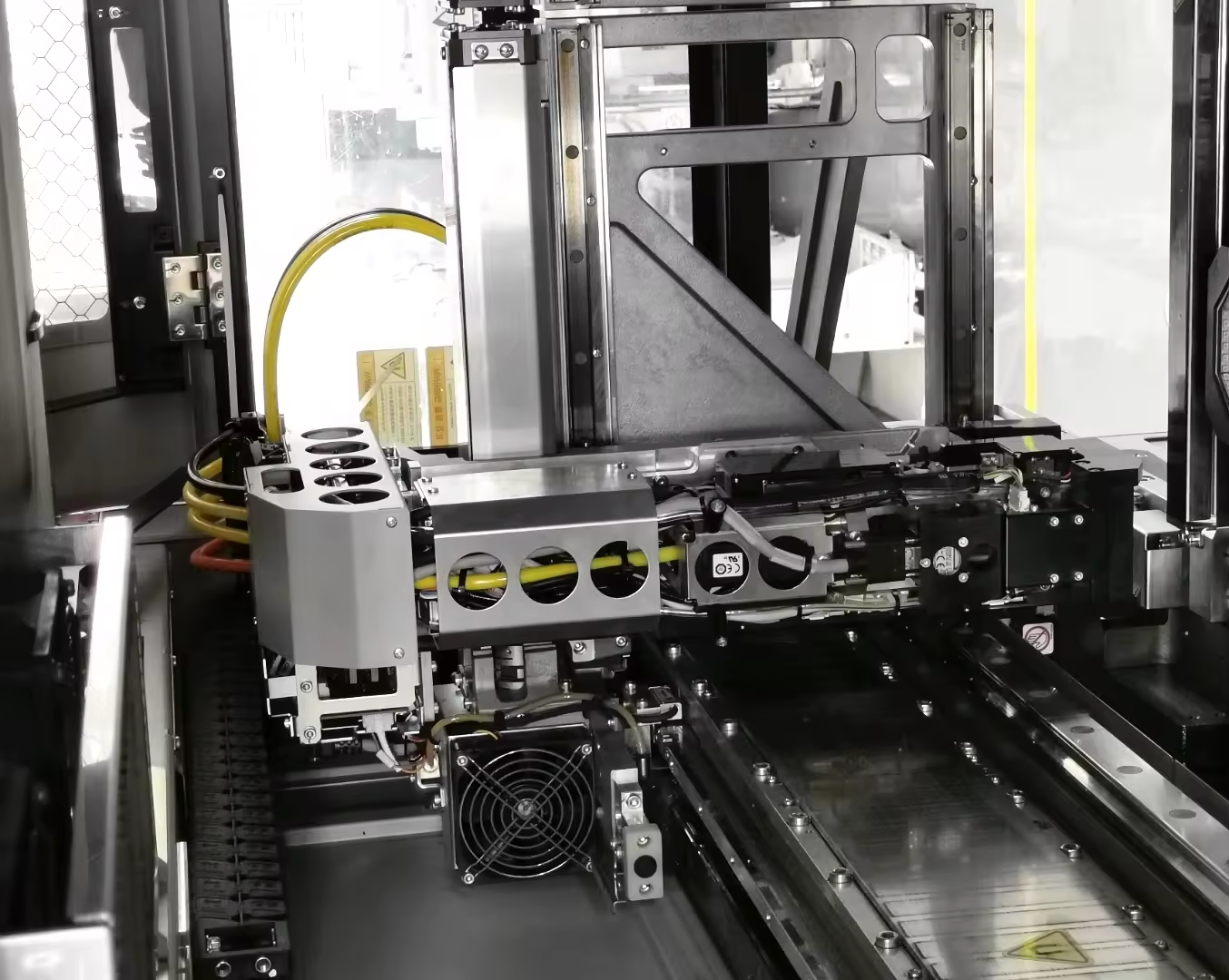

Detail Image

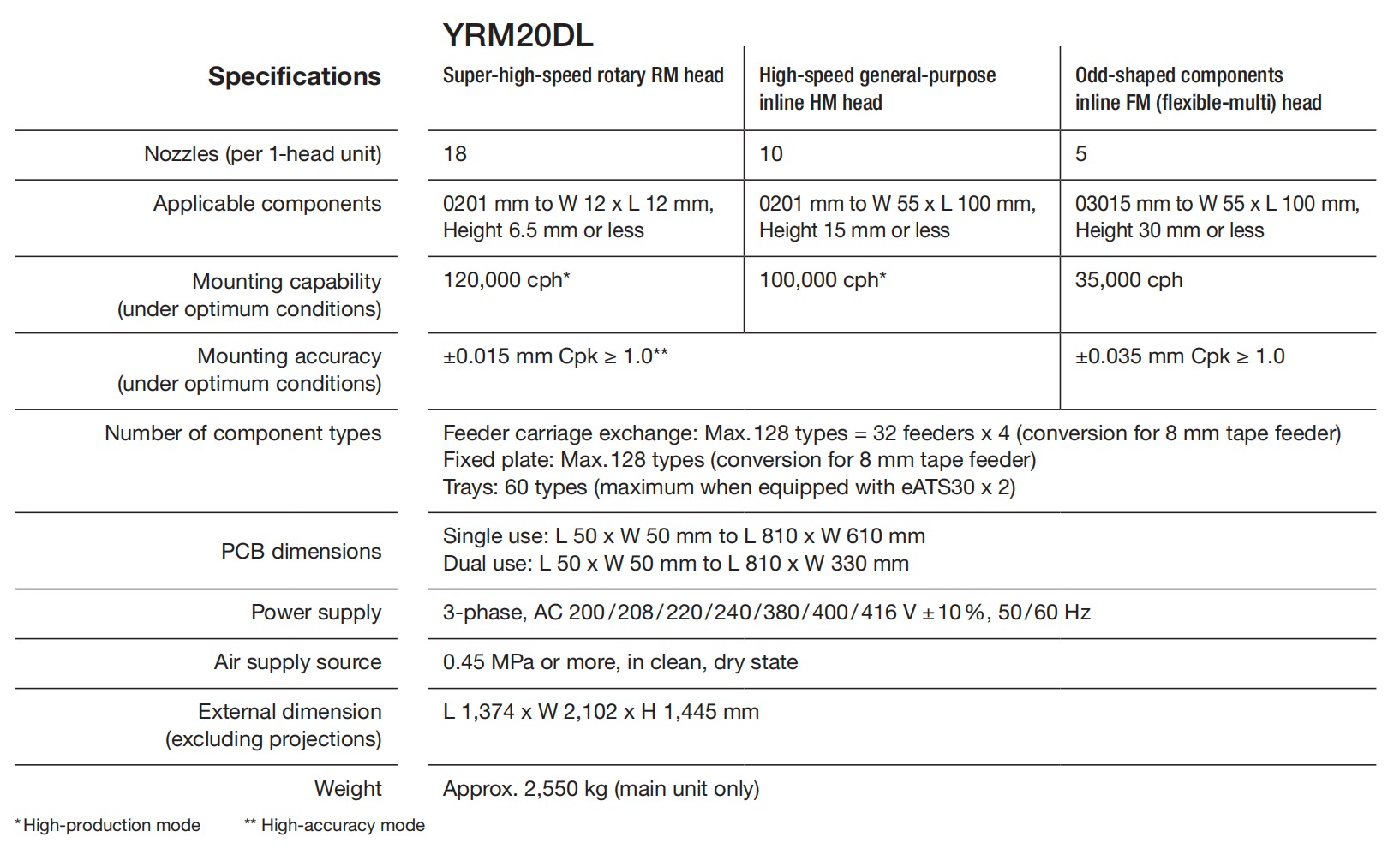

Specifications