Feature

Simple and reliable structure, accurate positioning and easy to adjust, the T5 can quickly achieve different thickness of the PCB board PIN height adjustment of the automatic adjustment. The spray nozzle makes the cleaning liquid evenly sprinkled on the wiping paper, and the arc-shaped rubber wipe board is soft, antiwear and antirust, clean thoroughly bidirectionally. It's easy to adjust the length of the common paper from 250mm to 520mm, and can be used for dry cleaning, wet wiping, wet cleaning, reciprocating cleaning and other functions.

Features:

Arch bridge gantry type scraper beam, programmable suspension type scraper head, precision screw automatically lifts and lowers the scraper pressure.

The system has three cleaning methods: dry cleaning, wet cleaning and vacuum cleaning, which can be used in any combination.

Using uniform ring light and high-brightness coaxial light, equipped with adjustable brightness function, so that various types of MARK points can be well identified, suitable for tinning, copper plating, gold plating, tin spraying, FPC and other types of different colors PCB.

Reliable structure, convenient adjustment, with three-axis linkage automatic correction function.

It adopts windows xp operation interface and has good man-machine dialogue function. The program file has teaching and navigation functions, and the operation interface has: operation log/fault record/fault self-diagnosis/light alarm function, simple operation.

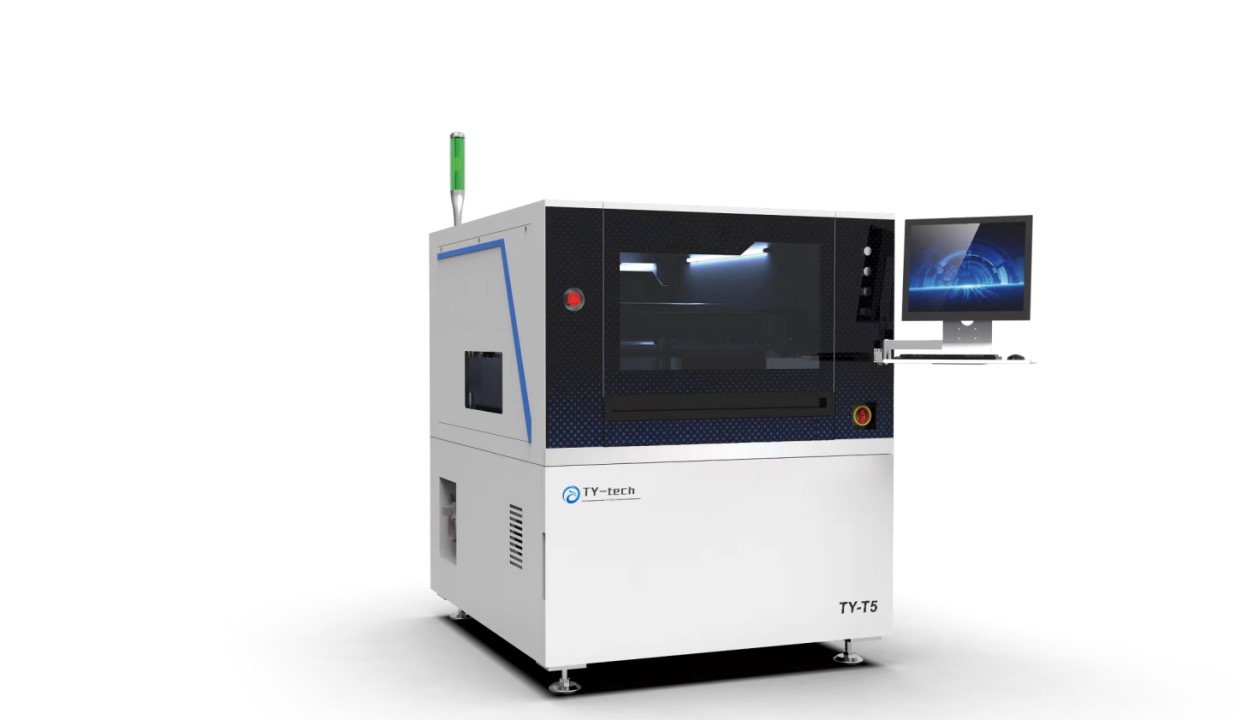

Detail Image

Specifications

| Category | Project | Spec |

| Operation page | Operation system | Windows 7 |

| Signal connection | SMEMA | |

| Visual system | Visual parameters | Up and down double vision, high performance CCD and image processing system |

| Printing accuracy | Repeat printing accuracy | ±0.01mm |

| Printing accuracy | ±0.025mm | |

| Cycle time | Printing cycle | <8s/pc (not include printing, cleaning time) |

| PCB parameter | Stencil size | 370*370mm~737*737mm |

| Frame fixed | Cylinder | |

| PCB size | 50*50mm~520*340mm | |

| PCB thickness | 0.4~6mm | |

| PCB weight | ≤3kg | |

| Support method | Magnetic thimble, magnetic ejector pin, manual crimping | |

| Delivery system | One-stage delivery system | |

| Transmission direction | L-R/R-L/L-L/R-R (software control) | |

| UVW platform adjustment range | Not lower than X:±3.5mm; Y:±6.5mm; e:±2° | |

| Platform/transfer parameters | PCB transmission height | 900±20mm |

| Platform adjustment angle | Z:±2° | |

| Squeegee speed | 10-180mm/s adjustable | |

| Printing parameters | Blade pressure | 0.5~10Kg |

| Release speed | 0~20mm/s adjustable | |

| Scraper angle | Standard type 60° | |

| Scrubbing method | Dry/Wet/VacuumFree combination of three modes | |

| Machine system | Software | Lifetime free maintenance and lifelong free software upgrades in time |

| Air supply | 4~6Kgf/cm2 | |

| Main power supply | AC:220V±10%, 50/60HZ, 2.5KW | |

| Machine size | L1200*W1320*H1519mm | |