Feature

GSK main intelligent configuration:

1. The standard version of the MES system can customize the output of Industry 4.0 solutions, which can record SOP and equipment open data and upload them

2. Temperature and humidity detection Real-time detection of temperature and humidity inside the device, which can be closed-loop controlled with the air conditioner

3. Panchao system camera scan code, compatible size: 3-3-7-7mm

4. SPI connection, automatic compensation for deviation and automatic cleaning of stencil for powder measurement and less tin

5. Safety control door opening machine, abnormal alarm

6. The authority setting can be set freely, and the authority division can be set for operators, technicians and engineers

7. Smart UI new interface, shortcut key operation

8. The electrical layout of BTB is at the front, and the equipment is combined into one to increase production capacity

9. Two sets of HTH equipment are used to print dramas together to increase production capacity

10. 2D inspection Detect less tin/missing printing/continuous tin

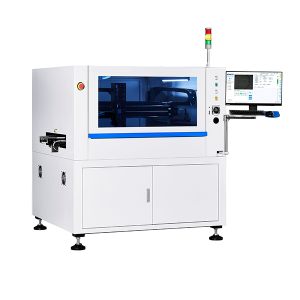

Detail Image

Specifications

| Machine performance | |

| Repeat position accuracy | ±12.5um@6 σ , CPK≥2.0 |

| Print accuracy | ±22um@6 σ , CPK≥2.0 |

| NCP-CT | 7s |

| HCP-CT | 18s/pcs |

| Process CT | 4min |

| Change line CT | 2min |

| Sudstrate processing parameter | |

| Max board size | 400*340mm (Option:530*340mm) |

| Min board size | 50*50mm |

| Board thickness | 0.4~6mm |

| Camera mechanical range | 528*340mm |

| Max board weight | 4kg |

| Board adge clearance | 2.5mm |

| Board height | 15mm |

| Transport speed | 900±40mm |

| (Max) Transport speed | 1500mm/s max |

| Transport direction | One stage |

| Transmission direction | Left to right |

| Right to left | |

| In and out the same | |

| Support system | Magnetic pin |

| Support block | |

| Manual up-down table | |

| Board damp | Automatic the top clamping |

| Side clamping | |

| Printing parameters | |

| Print speed | 10-200mm/s |

| Printing pressure | 0.5~10kg |

| Print mode | One/twice |

| Queegee type | Rubber, squeegee blade (angle 45/55/60) |

| Snap- off | 0-20mm |

| Sanp speed | 0-20mm/s |

| The template frame size | 470*370mm-737*737mm (thickness 20-40mm) |

| Positioning mode of steel mesh | Automatic Y-direction positioning |

| Cleaning parameteres | |

| Cleaning method | Dry, wet, vaccum, three modes |

| Cleaning system | Side drip type |

| Cleaning stroke | Automatic generation |

| Cleaning position | Post cleaning |

| Cleaning speed | 10-200mm/s |

| Cleaning fluid consumption | Auto/Manually adjustable |

| Cleaning pater consumption | Auto/Manually adjustable |

| Vision parameters | |

| CCD FOV | 10*8mm |

| Camera type | 130 thousand CCD digital camera |

| Camera system | Lock up/down optic structure |

| Camera cycle time | 150ms |

| Fiducial mark types | Standard fiducial mark shape |

| Round, square, diamond, cross | |

| Pad and profile | |

| Mark size | 0.1-6mm |

| Mark number | Max. 4pcs |

| Stay away number | Max. 1pc |

| Machine parameter | |

| Power source | AC 220 ±10%, 50/60Hz 2.2KW |

| Air pressure | 4~6kgf/cm² |

| Air consumption | ~5L/min |

| Operating temperature | -20°C~+45°C |

| Working invironment humidity | 30%-60% |

| Machine dimension (without flower light) | 1380(L)*1150(W)*1460(H)mm |

| Machine weight | Appr 900kg |

| Equipment load bearing requirements | 650kg/m² |