Reflow soldering yog txoj kev siv dav tshaj plaws ntawm kev txuas cov khoom sib txuas rau cov ntawv luam tawm Circuit Board (PCBs).Lub hom phiaj ntawm cov txheej txheem yog tsim cov pob qij txha siv tau los ntawm thawj zaug ua ntej cua sov cov khoom / PCB / solder paste thiab tom qab ntawd melting lub solder yam tsis muaj kev puas tsuaj los ntawm overheating.

Cov yam tseem ceeb uas ua rau kom muaj txiaj ntsig zoo reflow soldering txheej txheem yog raws li hauv qab no:

- Lub tshuab tsim nyog

- Txais tau reflow profile

- PCB/component footprint Design

- Ua tib zoo luam PCB siv cov stencil zoo

- Repeatable tso rau saum npoo mount Cheebtsam

- Zoo zoo PCB, Cheebtsam thiab solder paste

Tshuab tsim nyog

Muaj ntau hom reflow soldering tshuab muaj nyob ntawm qhov xav tau kab ceev thiab tsim / khoom ntawm PCB cov rooj sib txoos ua tiav.Lub qhov cub xaiv yuav tsum yog qhov tsim nyog los tswj tus nqi tsim khoom ntawm cov khoom tuaj tos thiab qhov chaw.

Cov kab nrawm tuaj yeem suav tau raws li qhia hauv qab no: -

Kab ceev (yam tsawg kawg) =Boards ib feeb x Length ib lub rooj tsavxwm

Load Factor (qhov chaw nruab nrab ntawm cov laug cam)

Nws yog ib qho tseem ceeb uas yuav tsum xav txog qhov rov ua dua ntawm cov txheej txheem thiab yog li 'Load Factor' feem ntau yog teev los ntawm lub tshuab tsim khoom, suav nrog hauv qab no:

Yuav kom xaiv qhov loj me me reflow qhov cub qhov txheej txheem ceev (txhais hauv qab no) yuav tsum ntau dua qhov tsawg kawg nkaus suav kab ceev.

Process ceev =Qhov cub chamber rhuab ntev

Cov txheej txheem nyob hauv lub sijhawm

Hauv qab no yog ib qho piv txwv ntawm kev suav los tsim qhov tseeb qhov cub loj: -

Ib tug SMT assembler xav tsim 8-nti boards ntawm tus nqi ntawm 180 ib teev.Cov chaw tsim tshuaj paus muab tshuaj txhuam pom zoo 4 feeb, peb kauj ruam profile.Ntev npaum li cas lub qhov cub kuv yuav tsum tau ua cov boards ntawm qhov kev nkag mus no?

Boards ib feeb = 3 (180 / teev)

Length per board = 8 nti

Load Factor = 0.8 (2-nti qhov chaw nruab nrab ntawm cov laug cam)

Lub Sijhawm Dwell = 4 feeb

Suav Kab Ceev:(3 boards / min) x (8 nti / board)

0.8 ua

Kab ceev = 30 nti / min

Yog li ntawd, qhov cub reflow yuav tsum muaj cov txheej txheem ceev ntawm tsawg kawg 30 ntiv tes ib feeb.

Txiav txim siab qhov cub chamber rhuab ntev nrog cov txheej txheem ceev sib npaug:

30 hauv / min =Qhov cub chamber rhuab ntev

4 feeb

Qhov cub cua sov ntev = 120 nti (10 ko taw)

Nco ntsoov tias tag nrho qhov ntev ntawm qhov cub yuav siab tshaj 10 feet nrog rau qhov cua txias thiab cov khoom thauj khoom thauj khoom.Kev suav yog rau HEATED LENGTH - TSIS TXHOB QHOV TSEEB.

1. Conveyor hom - Nws tuaj yeem xaiv lub tshuab nrog mesh conveyor tab sis feem ntau ntug conveyors tau teev tseg kom lub qhov cub ua haujlwm hauv-kab thiab tuaj yeem ua ob sab sib dhos.Ntxiv nrog rau cov ntug conveyor lub chaw nruab nrab-lub rooj txhawb nqa feem ntau suav nrog kom nres PCB los ntawm sagging thaum lub sij hawm reflow txheej txheem - saib hauv qab no.Thaum ua ob sab sib dhos siv cov ntug conveyor system saib xyuas yuav tsum tsis txhob cuam tshuam cov khoom nyob rau hauv qab.

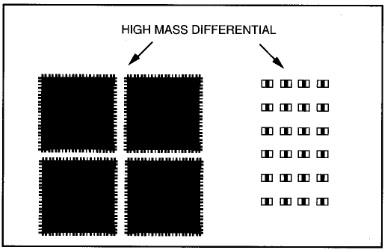

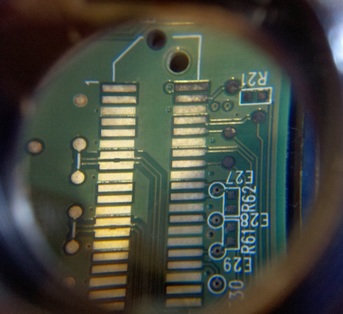

2. Kaw lub voj tswj kom ceev ntawm cov kiv cua convection - Muaj qee qhov chaw mount pob khoom xws li SOD323 (saib qhov ntxig) uas muaj qhov sib txuas me me rau qhov loj ntawm qhov sib piv uas raug cuam tshuam rau kev cuam tshuam thaum lub sij hawm reflow.Kaw lub voj ceev tswj ntawm lub rooj sib tham kiv cua yog ib qho kev pom zoo rau kev sib dhos uas siv cov khoom zoo li no.

3. Tsis siv neeg tswj cov conveyor thiab nruab nrab-board-txhawb dav dav - Qee lub tshuab muaj kev hloov dav dav tab sis yog tias muaj ntau lub rooj sib tham sib txawv yuav tsum tau ua tiav nrog qhov sib txawv PCB dav, qhov kev xaiv no tau pom zoo kom tswj cov txheej txheem sib xws.

Txais Reflow Profile

- Hom ntawm solder paste

- Cov khoom siv PCB

- PCB thickness

- Cov txheej txheem

- Tus nqi ntawm tooj liab hauv PCB

- Number ntawm nto mount Cheebtsam

- Hom nto mount Cheebtsam

Txhawm rau tsim kom muaj qhov reflow profile thermocouples txuas nrog cov qauv sib dhos (feem ntau nrog cov kub kub solder) hauv ntau qhov chaw los ntsuas qhov kub ntawm qhov kub ntawm PCB.Nws raug nquahu kom muaj tsawg kawg ib lub thermocouple nyob rau ntawm lub ncoo ntawm ntug ntawm PCB thiab ib lub thermocouple nyob rau ntawm lub ncoo ntawm nruab nrab ntawm PCB.Qhov zoo tshaj plaws thermocouples yuav tsum tau siv los ntsuas tag nrho cov ntsuas kub ntawm PCB - hu ua 'Delta T'.

Nyob rau hauv ib txwm reflow soldering profile feem ntau muaj plaub theem - Preheat, soak, reflow thiab txias.Lub hom phiaj tseem ceeb yog hloov cov cua sov kom txaus rau hauv lub rooj sib txoos kom yaj lub solder thiab tsim cov pob qij txha tsis ua rau muaj kev puas tsuaj rau cov khoom lossis PCB.

Preheat- Thaum lub sij hawm no lub Cheebtsam, PCB thiab solder yog tag nrho cov rhuab mus rau ib tug tshwj xeeb tsau los yog nyob rau hauv kub ceev ceev kom tsis txhob kub sai heev (feem ntau tsis ntau tshaj 2ºC / thib ob - xyuas solder paste datasheet).Cov cua kub ceev heev tuaj yeem ua rau muaj qhov tsis xws luag xws li cov khoom tawg thiab cov nplaum nplaum rau splatter ua rau cov khoom siv thaum lub sij hawm reflow.

Soak- Lub hom phiaj ntawm theem no yog kom ntseeg tau tias tag nrho cov khoom siv mus txog qhov kub thiab txias ua ntej nkag mus rau theem reflow.Soak feem ntau kav ntev li ntawm 60 mus rau 120 vib nas this nyob ntawm qhov 'qhov sib txawv ntawm qhov sib txawv' ntawm cov khoom sib dhos thiab cov khoom siv tam sim no.Qhov ua tau zoo dua qhov hloov hluav taws xob thaum lub sij hawm ntub dej tsawg dua lub sijhawm xav tau.

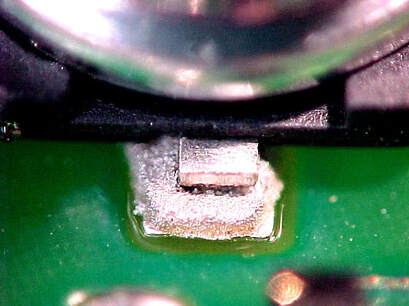

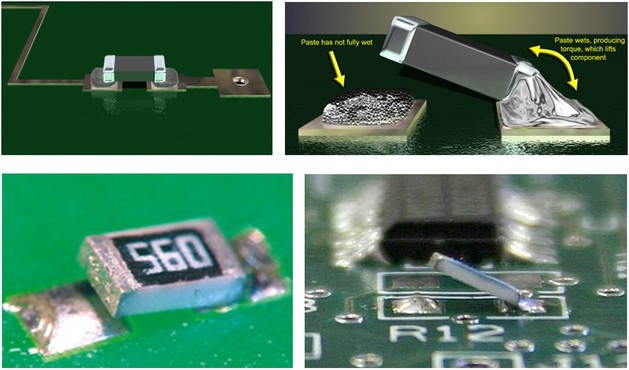

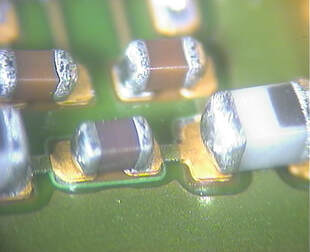

Ib qho kev tsis sib haum xeeb tom qab rov qab yog qhov tsim ntawm nruab nrab-chip solder pob / hlaws li tuaj yeem pom hauv qab no.Txoj kev daws teeb meem no yog hloov kho cov qauv stencil -Cov ntsiab lus ntxiv tuaj yeem pom ntawm no.

Txias- Qhov no tsuas yog theem thaum lub rooj sib txoos txias tab sis nws yog ib qho tseem ceeb kom tsis txhob txias lub rooj sib txoos sai heev - feem ntau qhov kev pom zoo ntawm qhov cua txias yuav tsum tsis pub tshaj 3ºC / thib ob.

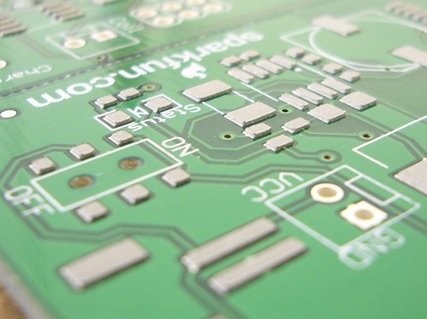

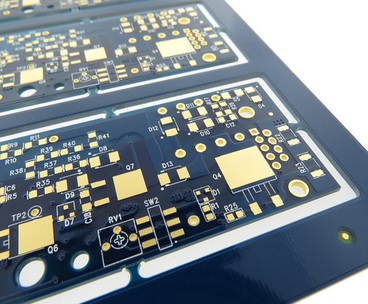

PCB/Component Footprint Tsim

Ua tib zoo luam PCB siv cov stencil zoo

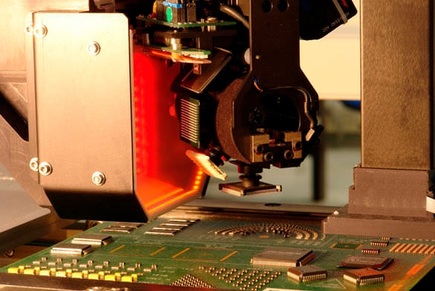

Repeatable tso rau saum npoo mount Cheebtsam

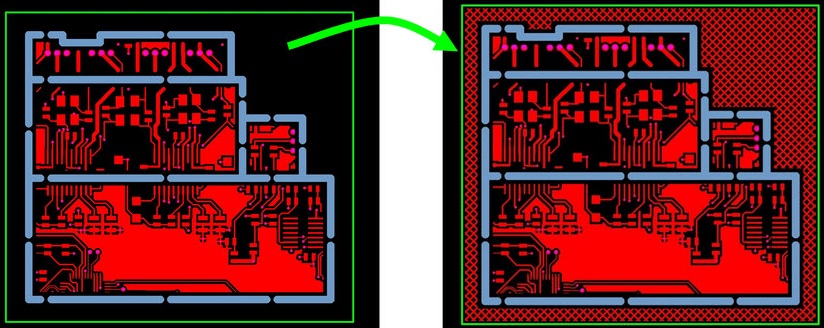

Cov kev pab cuam muab tso rau hauv cov khoom siv tuaj yeem tsim tau siv cov tshuab tuaj tos thiab tso tab sis cov txheej txheem no tsis raug raws li kev noj cov ntaub ntawv centroid ncaj qha los ntawm PCB Gerber cov ntaub ntawv.Feem ntau cov ntaub ntawv centroid no raug xa tawm los ntawm PCB tsim software tab sis qee zaum tsis muaj thiab yog li ntawdkev pabcuam los tsim cov ntaub ntawv centroid los ntawm Gerber cov ntaub ntawv yog muab los ntawm Surface Mount Process.

Txhua qhov chaw muab cov tshuab yuav muaj 'Placement Accuracy' teev tseg xws li: -

35um (QFPs) rau 60um (chips) @ 3 sigma

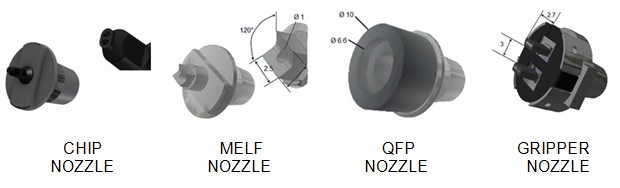

Nws tseem yog ib qho tseem ceeb rau qhov tseeb nozzle yuav raug xaiv rau hom kev tivthaiv yuav tsum tau muab tso rau - ntau yam sib txawv qhov chaw tso nozzles tuaj yeem pom hauv qab no: -

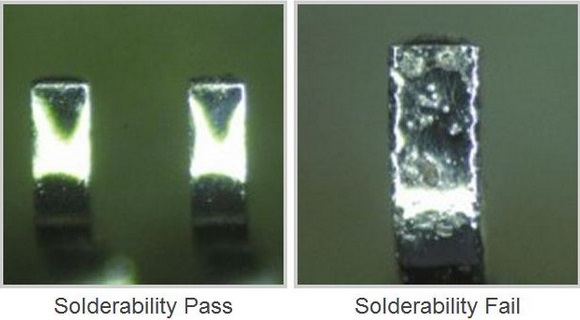

Zoo zoo PCB, Cheebtsam thiab solder paste

Post lub sij hawm: Jun-14-2022