Feature

Nta:

1. Siv lub tshuab micro electromagnetic twj tso kua mis tin rauv, lub tin nthwv dej yog siab, qhov ntws yog loj, lub ncov nthwv dej yog ruaj khov, qhov sib koom ua ke ntawm qhov tob tob yog qhov loj, thiab lub zog ntub dej thiab soldering muaj zog.

2. Lub periphery ntawm lub nozzle thiab qhov saum npoo ntawm lub solder yog kev tiv thaiv los ntawm nitrogen filling, uas yuav txhim khu lub solderability ntawm cov hlau lead-free solder, txo tus nqi ntawm tin slag generated, tiv thaiv lub nozzle los ntawm clogging, thiab txuag cov nqi welding thiab zog. tus nqi.

3. Qhov kub thiab txias tsis kam, corrosion kuj thiab cov nozzle tshwj xeeb, muaj zog oxidation tsis kam, zoo wettability, ib txwm siv sij hawm tuaj yeem ncav cuag 3 lub hlis.

4. Tsis siv neeg tshawb xyuas cov kua nplaum qib kom ruaj khov yoj peaks.

5. Nws muaj kev sib koom ua ke slimming muaj nuj nqi.

6. Los ntawm tus txheej txheem nrog ob lub koob yees duab CCD los saib xyuas cov txheej txheem vuam thiab PCB qhov chaw ua haujlwm.

Txheej txheem cej luam ntawm qhov kev pab cuam zoo:

n Tag nrho hauv ib lub tshuab, tuaj yeemhaum3 board lub3 pallet, ib qho hauv cov tshuaj tsuag flux, ib qho yog preheating, lwm qhov hauv soldering, tau txais txiaj ntsig ntau dua.

n Ib tug neeg tshuaj tsuag flux rooj & lub rooj soldering.

n High soldering zoo.

n SMEMA hauv kab kev sib txuas muaj peev xwm.

n Full PC tswj.Txhua yam tsis tuaj yeem teeb tsa hauv PC thiab khaws cia rau hauv PCB cov ntawv qhia zaub mov, xws li kev txav mus los, qhov kub thiab txias, hom flux, hom solder,N2kub thiab lwm yam, qhov zoo tshaj plaws kab-muaj peev xwm thiab yooj yim kom tau rov ua dua zoo dua.

Part 1: Software

- Tag nrho cov software tsim los ntawm tuam txhab los ntawm Tebchaws Meskas, nrog peb 8 xyoo kev paub txog kev xaiv soldering, pib ntawm Windows7 system, nrog rau kev muaj peev xwm zoo.

- Siv cov duab scanned ua keeb kwm yav dhau rau txoj kev programming, txav nrawm, nyob lub sijhawm, khoob txav nrawm, Z qhov siab, yoj qhov siab thiab lwm yam txhua qhov programmed rau qhov chaw sib txawv.

- Qhia cov txheej txheem solder nrog nyob ntawm lub koob yees duab.

- Cov tsis tseem ceeb yog tag nrho nyob rau hauv kev saib xyuas los ntawm PC software, xws li kub, ceev, siab thiab lwm yam.

- tuaj yeem hloov kho kom zoo nrog nws pib nthwv dej qhov siab calibration muaj nuj nqi, xyuas & calibrate yoj's qhov siab tom qab txhua yam pcb, yog li kom muaj kev ruaj ntseg zoo heev ntawm nthwv dej.

- Hais txog PCB's ntawv qhia zaub mov nyob rau hauv lub tshuab soldering, tag nrho cov ntaub ntawv yuav stocked nyob rau hauv ib cov ntaub ntawv.Nws yuav suav nrog PCB qhov ntev thiab daim duab, siv hom flux, hom solder, hom nozzle, solder kub, N2 kub, txoj kev txav thiab txhua qhov chaw's ntsig txog yoj qhov siab thiab Z qhov siab thiab lwm yam. Thaum cov neeg siv khoom siv tib lub PCB, lawv tuaj yeem tau txais cov ntaub ntawv tag nrho txog nws li cas's ua tiav hauv keeb kwm, kuj yooj yim rau kev taug qab.

Part 2: Kev txav system

- Tus kheej tsim cov lus tsa suab nrog cam khwb cia txhuas, sib dua yuag nrog cov lus tsa suab nrawm.

-

Panasonic servo lub cev muaj zog & tus neeg tsav tsheb muab lub zog tsav ruaj khov, nrog cov ntsia hlau ncej & linear guild rail rau kev taw qhia.Precious txoj hauj lwm, tsis tshua muaj suab nrov, ruaj khov txav.

- Nrog plua plav pov thawj phaj saum lub rooj lus tsa suab, yog li kom tsis txhob flux lossis solder poob kom puas lub pob ntsia hlau.

Ntu 3: Fluxing System

- Tus qauv nruab nrog lub dav hlau txawv teb chaws kom tau txais txiaj ntsig fluxing tshwm sim nrog me me flux dot, thov nco ntsoov cov ntsiab lus flux yuav tsum tsawg dua 10%.

- Flux yog stocked los ntawm PP yas siab tank, xyuas kom meej siab ruaj khov yam tsis cuam tshuam cov nyiaj flux.

Ntu 4: Preheat

- Ntawm conveyor sab saum toj & bottm nruab nrog IR preheating.Txoj hauj lwm yog adjustable.

- Cua sov piv yog adjustable los ntawm PC, los ntawm 0 --- 100%

Part 5: dual solder lauj kaub

- OBsolder lauj kaub system nrog tus kheej kub tswj, N2 kub tswj, yoj qhov siab tswj.Tag nrho cov ntsia hauv ib lub rooj.Qhov kev ncua deb ntawm ob lub lauj kaub tuaj yeem hloov kho.

- Kub kub, N2 kub, yoj qhov siab, nthwv dej calibration thiab lwm yam tuaj yeem teeb tsa hauv software.

- Lub lauj kaub yog ua los ntawm Ti, tsis to.Nrog cam khwb cia hlau rhaub sab nraud, muaj zog & ceev cua sov.

- Solder lauj kaub yog wired nrog ceev connector.Thaum pauv lub lauj kaub uas tsis tas yuav txuas txuas ntxiv, tsuas yog ntsaws & ua si.

- N2 hauv internet cua sov system, kom ntub cov soldering zoo kawg nkaus thiab txo cov solder dross.

- Nrog solder qib kuaj & tswb.

Ntu 6: Conveyor

- Stepper lub cev muaj zog tsav rau tsau & movable conveyor.

- Nrog stainless hlau cov menyuam rau conveyor, tsis hnav nrog kev siv ntev.Kuj xyuas kom meej tias lub nozzle tuaj yeem txav mus rau lub rooj tsavxwm's nqo 3mm.

- Nrog PCB clamping system ntawm conveyor.

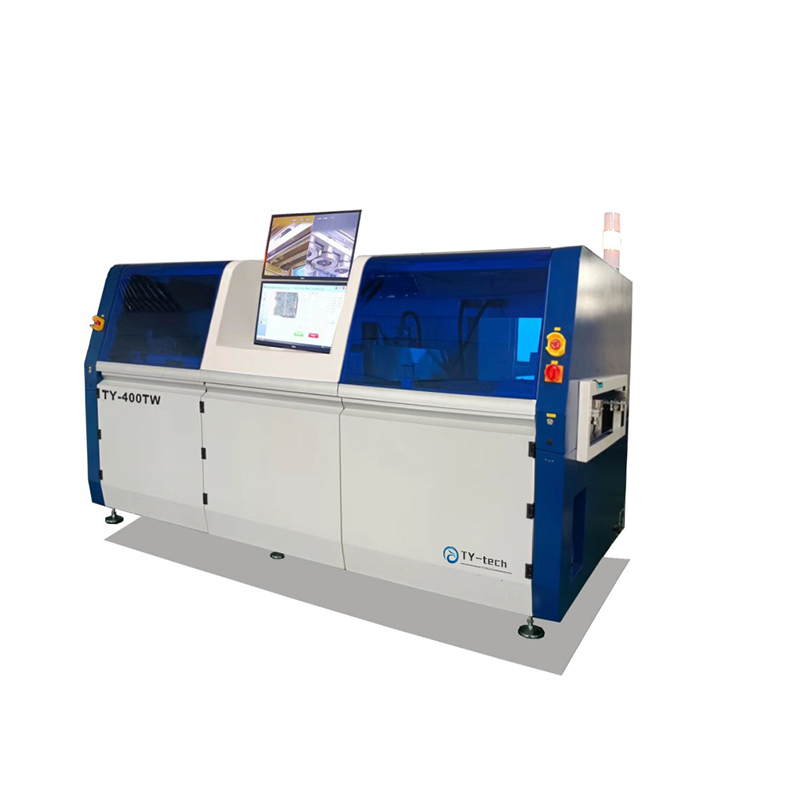

Daim duab nthuav dav

Specifications

| Qauv | TY-400 TWS-2 |

| General | |

| Dimension | L3100 * W1650 * H1650mm |

| General zog | 28 kwv |

| Kev siv zog | 6-10 kWm |

| Fais fab mov | Peb-theem tsib-xaim system 380V |

| Net nyhav | 350 KG |

| Yuav tsum tau cua qhov chaw | 3-5 Bars |

| Yuav tsum muaj cua ntws | 8-12L / min |

| Yuav tsum tau N2 siab | 3-4 Bars |

| Yuav tsum tau N2 ntws | > 4 cubic meters / teev |

| Yuav tsum tau N2 purity | 》99.998% |

| Yuav tsum tau qaug zog | Saum toj no cov tshuaj tsuag: 800--1000cbm / h Saum lub cub tawg: 600--800cbm / h |

| Carrier los yog PCB | |

| Tus neeg nqa khoom | Tsim nyog |

| Max PCB loj | L450 * W230MM * 2 Lus Cim: W yog lub tshuab dav kev taw qhia |

| Min tus cab kuj loj | L450 * W450MM Lus Cim: W yog lub tshuab dav kev taw qhia |

| Max solder cheeb tsam | L500 * W230MM * 2 Ceeb toom: W yog lub tshuab dav kev taw qhia |

| Pcb ntug | 3mm los yog ntau tshaj |

| Ctswj & conveyor | |

| Tswj | PLC + tswj |

| Conveyor dav | 300-600MM |

| Conveyor hom | Pin saw conveyor rau fluxing & preheating, cov menyuam conveyor rau soldering |

| Conveyor tuab | 1 ---- 4mm |

| Conveyor kev taw qhia | Sab laug mus rau sab xis |

| Conveyor nqa clearance | 100MM |

| Conveyor hauv qab clearance | 30MM |

| Conveyor load | <10kg |

| Conveyor rail | Aluminium rail |

| Conveyor qhov siab | 900 +/- 30mm |

| Tsab ntawv tsa suab(fluxing) | |

| Kev txav axis | X, Y |

| Kev tswj xyuas | Servo tswj |

| Txoj hauj lwm raug | + / - 0.05 hli |

| Chassis | hlau vuam |

| Kev tswj Flux | |

| Flux nozzle | dav hlau valve |

| Nozzle durability | stainless hlau |

| Flux tank peev xwm | 1L |

| Flux tank | siab tank |

| Preheat | |

| Preheat txoj kev | Sab saum toj & hauv qab IR cua sov |

| Cua sov lub zog | 16 kwv |

| Qhov kub thiab txias | 25-240 ° C |

| Motion Table (Soldering) | |

| Kev txav axis | X, Y, Z |

| Kev tswj xyuas | servo tswj |

| Lub cev muaj zog | Panasonic servo lub cev muaj zog |

| Pob ntsia hlau | Hiwin |

| Txoj hauj lwm raug | + / - 0.05 hli |

| Chassis | Hlau vuam |

| Squb lauj | |

| Standard lauj kaub naj npawb | 2 |

| Solder lauj kaub muaj peev xwm | 13kg / thawv * 2 |

| Solder kub ntau yam | PID |

| Lub sijhawm yaj | 60-70 feeb |

| Max solder kub | 350 ℃ |

| Solder rhaub | 1.2kw * 2 |

| Slaus nozzle | |

| Nozzle dim | customized |

| Khoom siv | siab carbon alloy |

| Standard nruab nozzle | Standard configuration: 5 daim / rauv ( puab txoj kab uas hla 3mm, 4mm, 5mm, 6mm, 8mm) |

| N2 kev tswj hwm | |

| N2 rhaub | txheem nruab |

| Nitrogen PID tswj N2 temp range | 0 - 350 ℃ |

| N2 siv | 1-2m3 / h / lauj kaub tag nrho: 4 m3 / h |