Feature

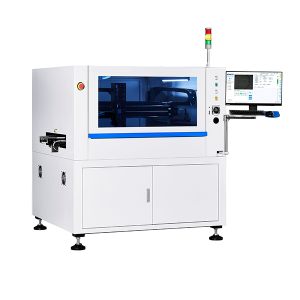

Tuam Tshoj SMT Chaw Tsim Tshuaj High Precision GKG Siab Tsis Siv Neeg Solder Paste Tshuab Luam Ntawv

1. GKG G9 + tsis siv neeg solder paste tshuab luam ntawv stencil nrhiav kom tau muaj nuj nqi:

Los ntawm kev ua lub teeb pom kev zoo tshaj qhov stencil, CCD yog siv los xyuas cov qhov mesh ntawm lub stencil hauv lub sijhawm tiag tiag, txhawm rau tshawb xyuas sai thiab txiav txim siab seb lub stencil puas raug thaiv tom qab ntxuav, thiab ua tsis siv neeg tu, uas yog 2D kuaj pom. txheej txheem rau PCB boards.Ntxiv ntxiv.

2. GKG G9 + tsis siv neeg solder paste tshuab luam ntawv tsis siv neeg dispensing system:

Raws li cov txheej txheem luam ntawv sib txawv, tom qab luam ntawv, raug xa tawm, tin dispensing, kab kos, sau thiab lwm yam kev ua haujlwm tuaj yeem ua rau ntawm PCB pawg thawj coj saib;Nyob rau tib lub sijhawm, lub taub hau dispensing kuj tau nruab nrog lub cua sov ua haujlwm, uas tuaj yeem siv rau hauv qhov kub thiab txias thaum cov kua nplaum tau rhuab, cov kua nplaum ntawm cov kua nplaum tau txhim kho.

3. GKG G9 + tsis siv neeg solder paste tshuab luam ntawv lub raj mis hom tsis siv neeg tin filling thiab solder paste nrhiav muaj nuj nqi:

Tsis siv neeg ntxiv solder paste nyob rau lub sij hawm tas los xyuas kom meej qhov zoo ntawm solder paste thiab tus nqi ntawm solder paste nyob rau hauv lub stencil.Txhawm rau kom ntseeg tau tias luam ntawv zoo ntawm cov neeg siv khoom thiab txhim kho kev tsim khoom.Los ntawm lub sensor, tus nqi ntawm solder paste rau ntawm stencil tuaj yeem tswj tau, thiab qhov zoo tuaj yeem ruaj khov.

Daim duab nthuav dav

Specifications

| Tshuab kev ua tau zoo | |

| Rov ua qhov tseeb qhov tseeb | ± 10um@6 σ, CPK≥2.0 |

| Kev luam ntawv raug | ± 18um@6 σ, CPK≥2.0 |

| NCP-CT | 7s |

| HCP-CT | 18s / pcs |

| Txheej txheem CT | 4 min |

| Hloov kab CT | 2 min |

| Substrate processing parameter | |

| Max board loj | 450 * 340 hli |

| Min board loj | 50 * 50mm |

| Board thickness | 0.4-6 hli |

| Lub koob yees duab mechanical range | 450 * 340 hli |

| Max board hnyav | 3kg ua |

| Board adge clearance | 2.5 hli |

| Board qhov siab | 15 hli |

| Kev thauj ceev | 900 ± 40 hli |

| (Max) thauj ceev | 1500mm / s max |

| Kev thauj mus los | Ib theem |

| Kev taw qhia kis | Sab laug mus rau sab xis |

| Txoj cai rau sab laug | |

| Hauv thiab tawm tib yam | |

| Kev them nyiaj yug system | Sib nqus pn |

| Txhawb nqa thaiv | |

| Manual up-down rooj | |

| Board damp | Tsis siv neeg sab saum toj clamping |

| Sab clamping | |

| Adsorption muaj nuj nqi | |

| Printing parameters | |

| Luam nrawm | 10-200mm / s |

| Kev luam ntawv siab | 0.5-10 kg |

| Hom ntawv luam tawm | Ib/ob zaug |

| Quegee hom | Roj hmab, squeegee hniav (lub kaum sab xis 45/55/60) |

| Snap-off | 0-20 hli |

| Sanp ceev | 0-20mm / s |

| Lub template ncej loj | 470 * 370mm-737 * 737mm (thickness 20-40mm) |

| Positioning hom ntawm steel mesh | Tsis siv neeg Y-kev taw qhia qhov chaw |

| Kev tu tsis tu ncua | |

| Ntxuav qhov system | Qhuav, ntub, vaccum, peb hom |

| Kev ceev ceev ceev | Integrated & weave tu |

| Ntxuav qhov system | Sab hom tshuaj tsuag |

| Kev tu mob stroke | Tsis siv neeg tiam |

| Ntxuav txoj hauj lwm | Ua ntej ntxuav |

| Kev ceev ceev | 10-200mm / s |

| Kev siv dej huv huv | Nws pib / manually adjustable |

| Ntxuav pater noj | Nws pib / manually adjustable |

| Lub zeem muag tsis pom kev | |

| CCD FOV | 10 * 8mm |

| Hom koob yees duab | 130 txhiab CCD lub koob yees duab digital |

| Lub koob yees duab system | Lock up/down optic qauv |

| Lub sijhawm lub koob yees duab | 100 ms |

| Fiducial cim hom | Standard fiducial mark puab |

| Hloov, square, pob zeb diamond, hla | |

| Pad thiab profile | |

| Mark loj | 0.1-6 hli |

| Kos tus lej | Max.4pcs ib |

| Nyob deb tus lej | Max.1pc ua |

| Tshuab parameter | |

| Lub zog | AC 220 ± 10%, 50 / 60Hz 2.2KW |

| Cua siab | 4 ~ 6 kgf / cm² |

| Kev siv cua | ~ 5L / min |

| Ua haujlwm kub | -20 ° C ~ + 45 ° C |

| Ua hauj lwm invironment humidity | 30% -60% |

| Tshuab dimension (tsis muaj paj teeb) | 1172 (L) * 1385 (W) * 1530 (H) hli |

| Tshuab hnyav | Txog 1000kg |

| Cov khoom siv load bearing xav tau | 650kg/m² |

-

GKG DLED Tsis Siv Neeg Glue Dsipener Tshuab

-

TYtech Fully Auto Screen Stencil tshuab luam ntawv F1200

-

GKG GSK High precision Screen tshuab luam ntawv

-

TYtech SMT Full Auto Stencil tshuab luam ntawv F450

-

Tag Nrho Tsis Siv Neeg DEK NeoHorizon 03iX Solder Paste ...

-

GKG Siab Tsis Siv Neeg Solder Paste Tshuab Luam Ntawv H1500