Feature

New solution of preheating

1.The hot air preheating u-shaped heater, long-service life, reduce maintenance downtime.

2. Internal reinforcement insulation plus optional external protction device can effectively reduce the heat loss, energy saving up to 20% compare with traditional equipment.

3. Low equipment surface temperature can optimize the working environment.

External Spray Fluxer, safety, cost, space and maintencance problems resolved.

1. External Spray Fluxer combined the advantages of inner and indenpendent spray, the spray and machine can be integrated control, no increase in cost.

2. Spray fluxer away from preheating zone, and ensure safety and clean.

3. Transportation of new type titanium alloy heavy duty claw, sectional guide rail design, stainless steel strip supported in guide rail, long life.

4. The solder pot adopts special, Anti corrosion coating on surface.

5. Adopt imported precision nozzle, atomization uniformity, high efficient.

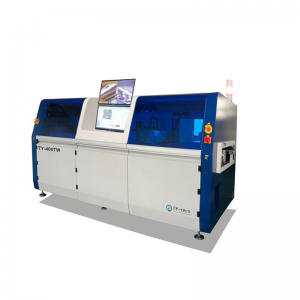

Detail Image

Specifications

| Model | 350 Series | 450 Series | 610 Series | ||

| SMART-350-M | SMART-350-H | SMART-450-M | SMART-450-H | SMART-610-H | |

| Dimension (L*W*H) | 3945*1582*1735mm | 4445*1582*1735mm | 3945*1582*1735mm | 4445*1582*1735mm | 4645*1742*1735mm |

| Spray Fluxer Dimension | 1300*1350*1595mm | 1400*1510*1595mm | |||

| Power Supply | AC 380V 3Φ5W 50/60HZ (Option: AC220V3P 50/60HZ) | ||||

| Initial/Operating Power | 45KW/≤9KW | 65KW/≤11KW | 45KW/≤10KW | 65KW/≤12KW | 90KW/≤13.5KW |

| Starting Power | 30KW | 30KW | 30KW | 30KW | 40KW |

| Air Source | 0.5-0.8Mpa | ||||

| Control System | PC+PLC | ||||

| Flux Flow | 10~100ml/min | ||||

| Exhaust Tube Diameter | Φ200mm | ||||

| Exhaust Mode | Upward | ||||

| Preheat Mode | IR/Hot air | ||||

| Preheat Zone Number | 3 zones/1800mm | 4 zones/2300mm | 3 zones/1800mm | 4 zones/2300mm | 4 zones/2300mm |

| Preheat Temp. Range | Room Temp. ~230°C | Room Temp. ~250°C | Room Temp. ~230°C | Room Temp. ~250°C | Room Temp. ~280°C |

| Temp. Control Mode | PID+SSR | ||||

| Solder Pot Type | Mechanical Pump | ||||

| Pot Capacity | Approx.480KG | Approx.550KG | Approx.800KG | ||

| Max. Soldering Temp. | |||||

| Wave Driving Power | 1/4HP X2 | ½HP X2Max: 300°C | ½HP X1+1HP X1 | ||

| Wave Height Control | Inverter | ||||

| Heat Up Time | Approx.140min (setting: 265°C) | Approx.150min (setting: 265°C) | Approx.160min (setting: 265°C) | ||

| PCB Conveyor Speed | 300~180mm/min | ||||

| The Width of PCb | 50-350mm | 50-450mm | 50-610mm | ||

| Component Height | Top 120mm/Bottom 25mm | ||||

| Transport Height | 750±20mm (Entrance) | ||||

| Conveyor Angle | 4~7° adjustable | ||||

| Conveyor Finger | Heavy duty double-hook finger claw | ||||

| Speed Control Mode | Inverter | ||||

| Cooling Method | Forced air cooling (option: chiller) | ||||

| N2 System | SMART-350-M-N | SMART-350-H-N | SMART-450-M-N | SMART-450-H-N | SMART-610-H-N |

| Nitrogen Consumption | 15m³/h 2000ppm | 18m³/h 2000ppm | |||

| Pressure Nitrogen Source | 0.5-0.8Mpa | ||||

| Oxygen Nitrogen Source | ≤10PPM | ||||

| Oxygen Analyzer | Option | ||||