-

Wave soldering machine instructions.

{ display: none; }A wave soldering machine is a type of soldering equipment used in electronic manufacturing. It achieves soldering of circuit boards by adding solder to the pads on the circuit board and using high temperature and pressure to fuse the solder to the circuit board. Here are the st...Read more -

SMT Automated production line equipment fault inspection and repair methods.

{ display: none; }1. Intuitive method The intuition method is based on the external manifestations of electrical faults in automated production line equipment, by means of seeing, smelling, listening, etc., to check and judge faults. 1. Check steps Investigation situation: Inquire about the situ...Read more -

What structures does a solder paste printing machine contain?

{ display: none; }Fully automatic solder paste printing machines generally include two parts: mechanical and electrical. The mechanical part is composed of transportation system, stencil positioning system, PCB circuit board positioning system, vision system, scraper system, automatic stencil c...Read more -

How to adjust the temperature of reflow oven?

Set the preheating temperature: The preheating temperature refers to the process of heating the plate to an appropriate temperature before welding. The setting of the preheating temperature should be determined according to the characteristics of the welding material, the thickness and size of t...Read more -

Handheld dry ice pcba cleaning machine advantages.

1) Low equipment investment cost and low dry ice consumption cost; 2) Full cleaning and partial cleaning can be selected, the cleaning is very flexible, and the operation is simple and convenient. 3) Zero pollution and zero discharge.Read more -

Several common ways of PCBA cutting.

1. Stamping: a. It is easy to cause PCBA circuit layer breakage, etc.; b. High efficiency; c. The accuracy cannot be controlled and the safety is low; 2. V-CUT board: a. It is easy to damage the PCBA and leave burrs after cutting; b. High efficiency and uncontrol...Read more -

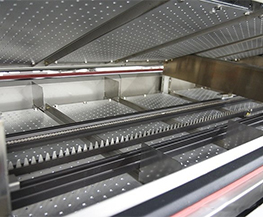

Wave soldering operation steps and points for attention.

1. Operation steps of wave soldering machine. 1). Wave soldering equipment preparation before welding Check whether the PCB to be soldered is damp, whether the solder joints are oxidized, deformed, etc.; the flux is connected to the nozzle interface of the sprayer. 2). Start-up of wave soldering...Read more -

How to improve the efficiency of reflow oven?

First of all, in order to improve the efficiency of reflow soldering equipment, we must start with the equipment itself to ensure the normal operation of the equipment. The normal operation of reflow soldering equipment not only requires the performance requirements of the equipment itsel...Read more -

Samsung Pick And Place Machine Shipment

Samsung Pick And Place Machine Shipment One set of SM481PLUS pick and place machine and 90pcs feeders ship out to our client. ...Read more -

SMT reflow soldering process optimization method.

The advantage of the SMT reflow oven process is that the temperature is easier to control, oxidation can be avoided during the soldering process, and the cost of manufacturing products is also easier to control. There is a set of electric heating circuits inside this device, which heats nitrogen ...Read more -

Why is reflow soldering called reflow?

Why is reflow soldering called “reflow”? The reflow of reflow soldering means that after the solder paste reaches the melting point of the solder paste, under the action of the surface tension of the liquid tin and the flux, the liquid tin reflows to the component pins to form solder ...Read more -

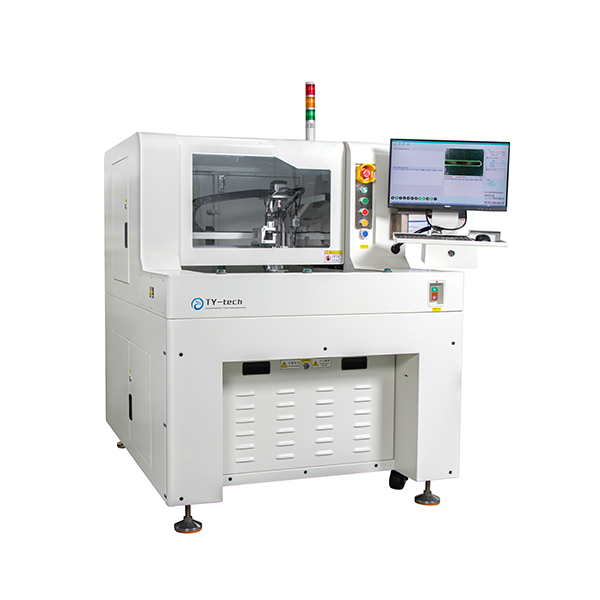

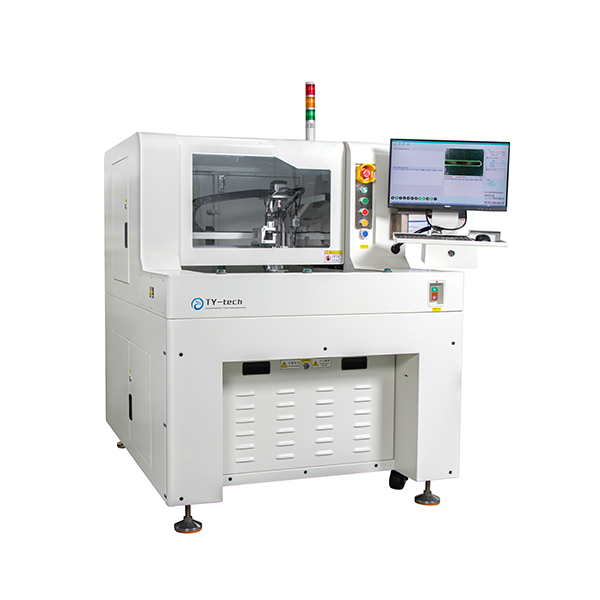

The difference between selective wave soldering and ordinary wave soldering.

The fundamental difference between selective wave soldering and ordinary wave soldering. Wave soldering is to contact the entire circuit board with the tin-sprayed surface and rely on the surface tension of the solder to climb naturally to complete the soldering. For large heat capacity and multi...Read more

Professional SMT Solution Provider

Solve any questions you have about SMT

- sales@tytech-smt.com

- +86 15361670575