-

How to improve the efficiency of reflow oven?

First of all, in order to improve the efficiency of reflow soldering equipment, we must start with the equipment itself to ensure the normal operation of the equipment. The normal operation of reflow soldering equipment not only requires the performance requirements of the equipment itsel...Read more -

Samsung Pick And Place Machine Shipment

Samsung Pick And Place Machine Shipment One set of SM481PLUS pick and place machine and 90pcs feeders ship out to our client. ...Read more -

SMT reflow soldering process optimization method.

The advantage of the SMT reflow oven process is that the temperature is easier to control, oxidation can be avoided during the soldering process, and the cost of manufacturing products is also easier to control. There is a set of electric heating circuits inside this device, which heats nitrogen ...Read more -

Why is reflow soldering called reflow?

Why is reflow soldering called “reflow”? The reflow of reflow soldering means that after the solder paste reaches the melting point of the solder paste, under the action of the surface tension of the liquid tin and the flux, the liquid tin reflows to the component pins to form solder ...Read more -

The difference between selective wave soldering and ordinary wave soldering.

The fundamental difference between selective wave soldering and ordinary wave soldering. Wave soldering is to contact the entire circuit board with the tin-sprayed surface and rely on the surface tension of the solder to climb naturally to complete the soldering. For large heat capacity and multi...Read more -

How to control the process parameters of reflow soldering equipment?

The main process parameters of reflow soldering equipment are heat transfer, chain speed control and wind speed and air volume control. 1. Control of heat transfer in soldering oven. At present, many products use lead-free technology, so the reflow soldering machine used now is mainly hot air ref...Read more -

Hot Selling SMT Economical PCB Stencil Printer

TYtech SMT Machine Factory Selling On-line full automatic printing machine, put the board on the machine and the suction nozzle will suck the board to print and then pass it to the next position. 1. Stable steel mesh fixed structure. 2. The track automatically adjusts the PCB width. 3. The lift t...Read more -

Small wave soldering machine.

Small wave soldering machine is also a reduced version of general large wave soldering. Its function is the same as that of large wave soldering, but its preheating zone is short and the tin furnace is relatively small. It is only suitable for trial production of electronic products and small bat...Read more -

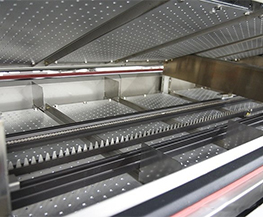

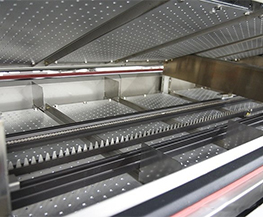

The role of reflow heating zone.

The heating area is in the first stage of the reflow soldering machine, preheating and heating the PCB board, activating the solder paste, volatilizing part of the solvent, and evaporating the moisture of the PCB board and components, eliminating the internal stress.Read more -

The main role of reflow oven.

The main application of reflow soldering is in the SMT process. In the SMT process, the main function of reflow oven is to put the PCB board with components mounted into the track of the reflow soldering machine. After heating, heat preservation, welding, cooling and other links, The solder paste...Read more -

How to choose a suitable pcb cutting machine.

{ display: none; }Many electronic product manufacturers produce PCB boards, and they have begun to choose to use pcb cutters because of the requirements of expanding production and improving product quality. But many people don’t know how to choose a pcb board cutting machine, thinking tha...Read more -

Wave soldering machine start-up production operation process.

Wave soldering machine start-up production operation process: 1. Turn on the flux switch, and adjust the thickness of the foam to 1/2 of the thickness of the board during foaming; when spraying, the board surface is required to be uniform, and the spray amount is appropriate, and it is generally ...Read more

Professional SMT Solution Provider

Solve any questions you have about SMT

- sales@tytech-smt.com

- +86 15361670575