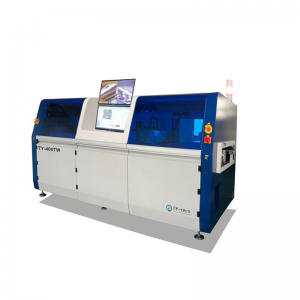

Kutsogola Kwaulere Kwaulere Kwa Air Reflow Oven TY-1220

Chiyambi:

1. The kompyuta mtundu ndi Siemens PLC dongosolo kulamulira wanzeru, mkulu mwatsatanetsatane kutentha kulamulira ndi ± 1-2 ℃ (ngati ngozi ngozi kompyuta, akhoza kuzindikira offline ntchito, sizimakhudza kupanga) ndi kuonetsetsa kuti dongosolo kulamulira ndi okhazikika ndi odalirika;

2. Mawindo XP ntchito mawonekedwe ndi wamphamvu ndi yosavuta ntchito.

3.Kuti mutsimikizire chitetezo ndi kudalirika, thupi la silinda likhoza kukwezedwa mmwamba.

4. Chipangizocho chili ndi lamba wa mauna, zoyendera bwino, osagwedezeka komanso osasinthika, zomwe zimatsimikizira kuyenda bwino kwa PCB.Njira yolumikizira kalozera wolumikizana ndi makina olumikizirana ndi makina a SMT pa intaneti amawonetsetsa kuwongolera kusinthika kosinthika komanso moyo wautumiki wapamwamba.

5. Makina owongolera opangira mafuta komanso unyolo wotumizira mafuta.

6.Kuwongolera kotentha konseko ndi makompyuta a PID (zone yakumtunda kwa kutentha ndi kukhazikitsa zone yotsika kutentha, zomwe zikutanthauza kuti zimatha kugawa kutentha kwa dera, kuti muchepetse mphamvu zoyambira)

7. Net / unyolo kufala ndi kompyuta kuchita lonse chatsekedwa kuzungulira ulamuliro, amene akhoza kukumana mitundu yosiyanasiyana ya kupanga PCB nthawi yomweyo.

8. Ndi phokoso lolakwika ndi ntchito ya alamu yopepuka.

9. Ndi kutayikira mtetezi, kuonetsetsa kuti ogwira ntchito ndi ulamuliro dongosolo chitetezo.

10.The UPS anamanga ndi basi kuchedwa shutdown dongosolo chitsimikizo kubwerera zitsulo zowotcherera mphamvu kapena kutenthedwa osati kuonongeka PCB ndi makina.

11. The German ERSA dziko kutsogolera akafuna microcirculation Kutentha mode, ndi chapamwamba ndi m'munsi palokha mpweya microcirculation dongosolo, kutentha kufanana ndi matenthedwe chipukuta misozi mkulu dzuwa, imayenera supercharged inapita patsogolo mpweya ngalande, bwino kwambiri kufalitsidwa otentha mpweya otaya, kutentha kutentha mwamsanga (za mphindi makumi awiri), chipukuta misozi cha kutentha kwambiri, kuwotcherera kwa kutentha kwambiri ndi kuchiritsa;

12. Kumtunda ndi kutsitsa kutentha kulikonse komwe kumakhala ndi sensa yodziyimira payokha, kuyang'anira nthawi yeniyeni ndi kubwezera kutentha kulikonse;

13. Kukhala ndi achinsinsi kasamalidwe ka opaleshoni dongosolo, kuteteza osafunika kusintha kwa ogwira ntchito magawo ndondomeko, mbiri kasamalidwe traceability ndondomeko magawo kusintha ndondomeko, kusintha kasamalidwe yabwino.Kusungirako liwiro la kutentha kwa wogwiritsa ntchito ndi Zikhazikiko za piritsi la kutentha, ndipo angagwiritsidwe ntchito pa data yonse ndi kusindikiza kopindika;

14. Integrated control zenera, chosinthira kompyuta, mayeso pamapindikira, kusindikiza pamapindikira ndi kufala deta mosavuta ntchito, humanized kapangidwe.Okonzeka ndi njira zitatu kutentha pamapindikira pa Intaneti kuyezetsa dongosolo, akhoza nthawi iliyonse kufufuza kuwotcherera zinthu ndi kutentha pamapindikira (popanda machesi kutentha pamapindikira Tester);

15. Kuchokera kuukadaulo wapadziko lonse lapansi kuzirala kwachangu, gwiritsani ntchito kuziziritsa kwagalasi kokulirapo kofulumira kuzirala, liwiro lozizira limatha kufika 3.5 ~ 6 ℃/ SEC, kasamalidwe ndi yabwino kwambiri;Kunja kukakamizidwa kuzirala chipangizo, kuonetsetsa kuti malo galasi zotsatira (Njira anasankha zinthu, muyezo kasinthidwe kukakamiza zachilengedwe kuzirala mpweya).

Kufotokozera:

| Chitsanzo | Mtengo wa TY-Tech 1220 | ||

| Heating System | Chiwerengero cha madera otentha | Pamwamba pa 12/ pansi 12 | |

| Chiwerengero cha madera ozizira | 2 | ||

| Kutalika kwa madera otentha | 4640 mm | ||

| Kutentha mode | Mpweya wotentha | ||

| Njira Yozizirira | Kuziziritsa mpweya mokakamiza | ||

| Mphamvu ya Exhaust | 10m³/mphindi * 2 zotopetsa | ||

| Conveyor System | Max.Mtengo wapatali wa magawo PCB | 400 mm | |

| Mesh lamba m'lifupi | 450 mm | ||

| Njira yotumizira | L→R(njira: R→L) | ||

| Transmission Net Height | 900 ± 20mm | ||

| Mtundu wotumizira | Mesh ndi unyolo | ||

| M'lifupi mwake njanji | 400 mm | ||

| Liwiro la conveyor | 0-2000mm / mphindi | ||

| Auto/Manual Lubrication | Standard | ||

| Mbali ya njanji yokhazikika | Sitima yakutsogolo yokhazikika (njira: njanji yakumbuyo yokhazikika) | ||

| Zigawo zapamwamba | Pamwamba ndi pansi 25mm | ||

| Dongosolo lowongolera | Magetsi | 5 mzere 3 gawo 380V 50/60HZ | |

| Mphamvu zonse | 48kw pa | ||

| Kugwiritsa ntchito mphamvu mwachizolowezi | 10-12KW | ||

| Nthawi yofunda | 20 mins | ||

| Temp.kuyika range | Kuyambira kutentha kwachipinda.Mpaka 300 ℃ | ||

| Temp.njira yolamulira | PID close loop control & SSR drive | ||

| Temp.kuwongolera molondola | ±1℃ | ||

| Temp.kusintha kwa PCB | ±2℃ | ||

| Kusungirako deta | Sinthani Data ndi malo osungira (80GB) | ||

| Nozzle mbale | Aluminium Alloy Plate | ||

| Alamu yachilendo | Kutentha kwachilendo (kutentha kwambiri / kutsika kwambiri) | ||

| Board idatsitsa alarm | Tower light:Yellow-kutentha, Green-yachibadwa, Red-abnormal | ||

| General | Dimension(L*W*H) | 6300*1320*1490mm | |

| Kulemera | 2600kg | ||

| Mtundu | Kompyuta imvi | ||

Mawu osakira:SMT Reflow Oven, Lead free Reflow Oven, High end reflow uvuni, Reflow Soldering Oven, Reflow Oven Manufacture, Led Reflow Oven, PCB Reflow Oven, Nayitrogeni Reflow Oven, Dual Lane Reflow Oven, China Reflow Oven, PCB Soldering Machine

FAQ:

Q. Kodi chosowa chanu cha MOQ pamakina ndi chiyani?

A. 1 adayika zofunikira za moq pamakina.

Q. Aka ndi koyamba kugwiritsa ntchito makina otere, ndi osavuta kugwiritsa ntchito?

Yankho: Pali buku lachingerezi kapena vidiyo yotsogolera yomwe imakuwonetsani momwe mungagwiritsire ntchito makina.

Q: Ngati makinawo ali ndi vuto lililonse tikalandira, tingachite bwanji?

A: Katswiri wathu athandizira kuthetsa izi poyamba, ndipo magawo aulere amatumiza kwa inu munthawi ya chitsimikizo cha makina.

Q: Kodi mumapereka chitsimikizo chilichonse pamakina?

A: Inde 1 chaka chitsimikizo adzaperekedwa kwa makina.

Q: Ndingakuikireni bwanji?

A: Mutha kutifikira kudzera pa imelo, whatsapp, wechat ndikutsimikizira mtengo wake womaliza, njira yotumizira komanso nthawi yolipira, ndiye tidzakutumizirani invoice ya proforma yokhala ndi zambiri zaku banki kwa inu.