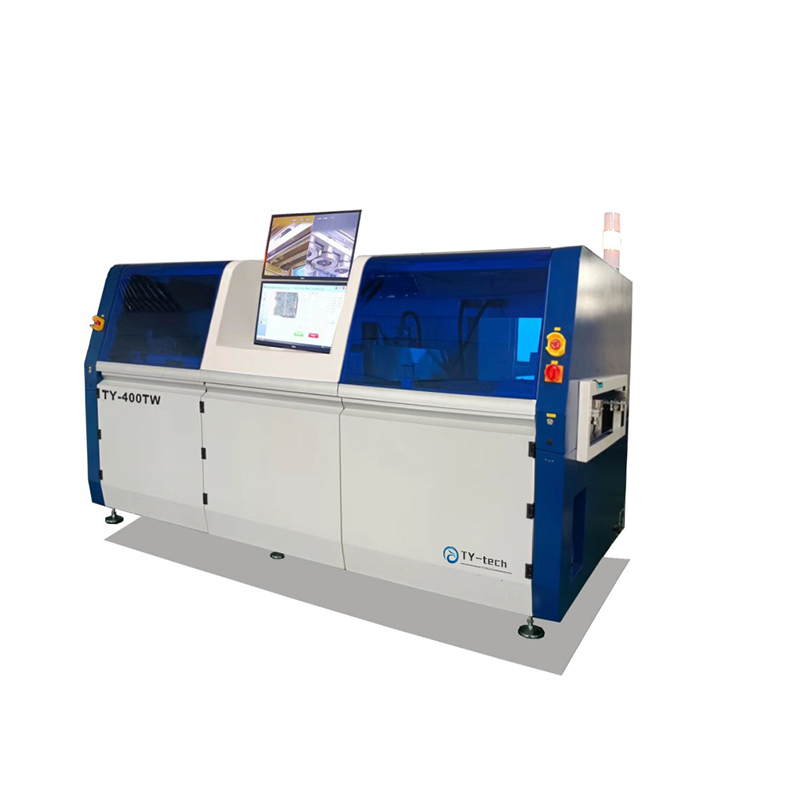

Mbali

Mawonekedwe:

1. Pogwiritsa ntchito ng'anjo ya tini ya micro electromagnetic pump, mafunde a tini ndi okwera, kutuluka kwake kuli kwakukulu, nsonga ya mafunde imakhala yokhazikika, kuya kwa kulowetsedwa kwa solder ndi kwakukulu, ndipo mphamvu yonyowetsa ndi soldering ndi yolimba.

2. Mphepete mwa mphuno ndi pamwamba pa solder zimatetezedwa ndi kudzazidwa kwa nayitrogeni, zomwe zingapangitse kusungunuka kwa solder wopanda kutsogolera, kuchepetsa kuchuluka kwa malata opangidwa, kuteteza nozzle kuti zisatseke, ndikupulumutsa ndalama zowotcherera ndi ntchito. ndalama.

3. Kukana kutentha kwakukulu, kukana kwa dzimbiri ndi nozzle yapadera, kukana kwa okosijeni mwamphamvu, kunyowa kwabwino, nthawi yogwiritsira ntchito nthawi zonse imatha kufika miyezi itatu.

4. Zindikirani zokha za solder madzi mlingo kuonetsetsa khola nsonga yoweyula.

5. Iwo ali solder olowa slimming ntchito.

6. Imabwera muyeso ndi makamera awiri a CCD kuti aziyang'anira momwe kuwotcherera ndi PCB poyika mapulogalamu.

Chidule cha ubwino wa pulogalamu:

n Zonse mu makina amodzi, akhozakhalamo3 mapepala kapena3 pallet, imodzi yopopera, imodzi imatenthedwa, ina yowotchera, ipeza zokolola zambiri.

n Tebulo lopoperapo aliyense payekhapayekha & tebulo la soldering.

n Kutentha kwambiri.

n SMEMA yolumikizana ndi mzere imatha.

n Kuwongolera kwathunthu kwa PC.Magawo onse amatha kukhala mu PC ndikusungidwa ku menyu ya PCB, monga njira yosunthira, kutentha kwa solder, mtundu wa flux, mtundu wa solder,N2kutentha ndi zina, luso lofufuza bwino komanso zosavuta kubwereza khalidwe la soldering.

Gawo 1: Mapulogalamu

- Makina onse apulogalamu opangidwa ndi kampani yaku USA, ndi zaka 8 zakuchitikira pazakusankhira, kutengera Windows7 system, yokhala ndi luso lofufuza.

- Gwiritsani ntchito chithunzi chojambulidwa ngati chakumbuyo kwa njira, kuthamanga, nthawi yokhalamo, liwiro lopanda kanthu, kutalika kwa Z, kutalika kwa mafunde ndi zina zonse zopangidwira malo osiyanasiyana ogulitsa.

- Onetsani ndondomeko ya solder yokhala ndi kamera yamoyo.

- Magawo ofunikira amawunikidwa kwathunthu ndi mapulogalamu a PC, monga kutentha, kuthamanga, kuthamanga, etc.

- Itha kukwezedwa kuti ikhale ndi auto wave height calibration ntchito, kuyang'ana & kuwongolera mafunde's kutalika pambuyo pa pcb iliyonse, kotero kusunga bata wabwino kwambiri wa yoweyula.

- Za PCB's mumakina ogulitsira, zidziwitso zonse zidzasungidwa mufayilo imodzi.Iphatikiza kukula kwa PCB ndi chithunzi, mtundu wa flux wogwiritsidwa ntchito, mtundu wa solder, mtundu wa solder nozzle, kutentha kwa solder, kutentha kwa N2, njira yoyenda ndi tsamba lililonse.'s zokhudzana yoweyula kutalika ndi Z kutalika etc. Pamene kasitomala kuti solder PCB chomwecho, iwo akhoza kudziwa zonse mmene izo'zachitika m'mbiri, komanso zosavuta kufufuza.

Gawo 2: mayendedwe kachitidwe

- Tebulo lodzipangira lokha lokhala ndi aluminiyamu wonyezimira, kulemera kopepuka komanso kuthamanga kwachangu.

-

Panasonic servo motor & driver amapereka mphamvu yoyendetsa yokhazikika, yokhala ndi screw pole & linear gulu njanji kuti iwatsogolere.Malo amtengo wapatali, phokoso lochepa, kuyenda kokhazikika.

- Ndi mbale yotsimikizira fumbi pamwamba pa tebulo loyenda, kuti mupewe kutsika kapena kutsika kwa solder kuwononga wononga mpira.

Gawo 3: Fluxing System

- Zokhazikika zokhala ndi valavu ya jet yotumizidwa kunja kuti mupeze zotsatira zosinthika ndi kadontho kakang'ono, chonde dziwani kuti zolimba zolimba ziyenera kukhala zosakwana 10%.

- Flux imakhala ndi thanki ya PP ya pulasitiki, onetsetsani kuti kupanikizika kukhazikika popanda kukhudzidwa ndi kuchuluka kwa kutuluka.

Gawo 4: Preheat

- Pa conveyor top & bottm yokhala ndi IR preheating.Udindo ndi wosinthika.

- Chiyerekezo cha kutentha chimasinthidwa ndi PC, kuchokera ku 0 ---100%

Gawo 5: Mphika wapawiri wa solder

- ZIWIRIsolder pot system yokhala ndi kutentha kwa munthu payekha, kuwongolera kutentha kwa N2, kuwongolera kutalika kwa mafunde.Onse anaika mu tebulo limodzi.Mtunda pakati pa mphika wa solder ukhoza kusinthidwa.

- Kutentha kwa solder, kutentha kwa N2, kutalika kwa mafunde, kusintha kwa mafunde ndi zina zonse zomwe zimatha kukhazikitsa mapulogalamu.

- Mphika wa solder umapangidwa ndi Ti, osati kutayikira.Ndi chotenthetsera chachitsulo choyatsidwa kunja, chotenthetsera champhamvu & mwachangu.

- Mphika wa solder uli ndi mawaya ndi cholumikizira mwachangu.Mukasinthana poto ya solder popanda kuyimitsanso waya wofunikira, ingolumikizani ndikusewera.

- Makina otenthetsera pa intaneti a N2, kuti anyowetse zowotchera bwino ndikuchepetsa dothi la solder.

- Ndi macheke a solder & alarm.

Gawo 6: conveyor

- Stepper motor drive yama conveyor okhazikika & osunthika.

- Ndi chodzigudubuza chachitsulo chosapanga dzimbiri chotumizira, chosavala ndikugwiritsa ntchito nthawi yayitali.Komanso onetsetsani kuti solder nozzle imayandikira pa board'm'mphepete 3mm.

- Ndi PCB clamping system pa conveyor.

Tsatanetsatane Chithunzi

Zofotokozera

| Chitsanzo | TY-400TW-2 |

| General | |

| Dimension | L3100 * W1650 * H1650mm |

| Mphamvu zonse | 28kw pa |

| Kugwiritsa ntchito mphamvu | 6-10kw |

| Magetsi | Atatu gawo asanu waya dongosolo 380V |

| Kalemeredwe kake konse | 350KG |

| Zofunika mpweya | 3-5 Mipiringidzo |

| Kuyenda kwa mpweya kumafunika | 8-12L/mphindi |

| Kuthamanga kwa N2 kumafunika | 3-4 Mipiringidzo |

| Kuthamanga kwa N2 kumafunika | > 4 kiyubiki mita / ola |

| Zofunika N2 chiyero | 》99.998% |

| Kutopa kumafunika | Pamwamba pa kutsitsi: 800---1000cbm/h Pamwamba pa ng'anjo ya malata: 600---800cbm/h |

| Cchotengera kapena PCB | |

| Wonyamula | Zofunikira |

| Kukula kwakukulu kwa PCB | L450 * W230MM * 2 Zindikirani: W ndiye njira yofikira makina |

| Kukula kochepa konyamulira | L450 * W450MM Zindikirani: W ndiye njira yofikira makina |

| Max solder dera | L500 * W230MM * 2 Zindikirani: W ndiye njira yofikira makina |

| pcb pa | 3 mm kapena kuposa |

| Ckuyang'anira & conveyor | |

| Kulamulira | PLC + wowongolera |

| Conveyor m'lifupi | 300-600 mm |

| Mtundu wa conveyor | Pin unyolo conveyor kwa fluxing & preheating, wodzigudubuza conveyor kwa soldering |

| Conveyor wandiweyani | 1---4 mm |

| Mayendedwe a conveyor | Kumanzere kupita kumanja |

| Kuwongolera kwa conveyor | 100MM |

| Conveyor pansi chilolezo | 30 mm |

| Katundu wa conveyor | <10kg |

| Sitima ya conveyor | Sitima ya Aluminium |

| Kutalika kwa conveyor | 900+/-30mm |

| Zoyenda tebulo(kuyenda) | |

| Mzere woyenda | X, Y |

| Kuwongolera kuyenda | Servo control |

| Kulondola kwamalo | + / - 0.05 mm |

| Chassis | kuwotcherera zitsulo |

| Kuwongolera kwa Flux | |

| Flux nozzle | valavu ya jet |

| Nozzle durability | chitsulo chosapanga dzimbiri |

| Mphamvu ya tanki ya Flux | 1L |

| Flux tank | tank pressure |

| Preheat | |

| Preheat njira | Kutentha kwapamwamba & pansi kwa IR |

| Mphamvu ya heater | 16kw pa |

| Kutentha kosiyanasiyana | 25--240c digiri |

| Zoyenda tebulo (soldering) | |

| Mzere woyenda | X, Y, Z |

| Kuwongolera kuyenda | servo control |

| Makina oyenda | Panasonic servo motor |

| Mpira konda | Hiwin |

| Kulondola kwamalo | + / - 0.05 mm |

| Chassis | Kuwotcherera zitsulo |

| Smphika wakale | |

| Nambala ya pot yokhazikika | 2 |

| Kuchuluka kwa mphika wa solder | 13 kg / mphika * 2 |

| Kutentha kwa solder | PID |

| Nthawi yosungunuka | 60-70 Mphindi |

| Kutentha kwakukulu kwa solder | 350 ℃ |

| Solder chotenthetsera | 1.2kw*2 |

| Snozzle wamkulu | |

| Nozzle mdima | makonda |

| Zakuthupi | high carbon alloy |

| Standard zida nozzle | Standard kasinthidwe: 5 zidutswa / ng'anjo (m'mimba mwake 3mm, 4mm, 5mm, 6mm, 8mm) |

| Utsogoleri wa N2 | |

| N2 heater | muyezo zida |

| Nitrogen PID control N2 temp range | 0 - 350 ℃ |

| N2 kudya | 1-2m3/h/mphika wonse: 4 m3/h |

-

8 Magawo Otenthetsera Ubwino Wowonjezera Wowonjezera Wowonjezera O ...

-

Mirtec 3D Inline SPI Inspection Machine MS-11

-

PCBA Cleaning Machine Pakuti SMT Machine Line PCB ...

-

Hanwha Multi Functional Chip Mounter HM520W

-

Wave Soldering Insertion Production Line 2.4M

-

China Wholesales Reflow Oven, SMT Reflow Solder...