Mbali

1. Kompyuta ya Brand LCD + PLC intelligent control system imatengedwa, yokhala ndi kutentha kwapamwamba kwambiri kwa ± 1 ° C (ngati kompyuta ikuphwanyidwa mosayembekezereka, ntchito yapaintaneti imatha kuchitika popanda kukhudza kupanga), kuonetsetsa kukhazikika ndi kudalirika kwa dongosolo lowongolera. ;

2. Mawindo 7 ntchito mawonekedwe, wamphamvu ndi yosavuta kugwiritsa ntchito;

3. Kutsegula kwa thupi la ng'anjo yapamwamba kumatenga makina awiri amagetsi a jacking kuti atsimikizire chitetezo ndi kudalirika;

4. Okonzeka ndi mauna lamba tensioning chipangizo, mayendedwe ndi khola, palibe kugwedeza, palibe mapindikidwe, kuonetsetsa kayendedwe yosalala PCB;

5. Synchronous guide njanji transmission mechanism (ikhoza kulumikizidwa pa intaneti ndi makina oyika okha) kuonetsetsa kusintha kolondola kwa njanji ndi moyo wautali wautumiki;(posankha njanji yowongolera)

6. Kuwongolera mokhazikika dongosolo lopaka mafuta, lomwe limatha kupatsanso mafuta unyolo pokhazikitsa nthawi yamafuta ndi kuchuluka kwamafuta;

7. Magawo onse otenthetsera ndi PID olamulidwa ndi kompyuta (malo otentha amatha kutsegulidwa padera. Kutentha kumatha kugawidwa m'magawo kuti muchepetse mphamvu yoyambira);

8. Kutumiza kwa maukonde / unyolo kumakhala kotsekedwa kwathunthu koyendetsedwa ndi kompyuta, yomwe imatha kukumana ndi kupanga munthawi yomweyo mitundu yosiyanasiyana ya ma PCB;

9. Ndi phokoso lolakwika ndi ntchito ya alamu yopepuka;

10. Okonzeka ndi kutayikira mtetezi kuonetsetsa chitetezo cha ogwira ntchito ndi dongosolo ulamuliro;

11. UPS womangidwa ndi makina otsekemera ochedwa kuti atsimikizire kuti PCB ndi reflow soldering makina sizidzawonongeka pamene mphamvu ikudulidwa kapena kutenthedwa;

12. Landirani njira yotentha ya HELLER yotenthetsera mpweya wotentha, wothamanga kwambiri wothamanga kwambiri, amawonjezera kwambiri kutuluka kwa mpweya wotentha, kutentha kwachangu (pafupifupi mphindi 10), kutentha kwakukulu kwa kutentha, ndi kuwotcherera ndi kuchiritsa;

13. Malo otentha amakhala ndi chojambulira chodziyimira pawokha chowunikira kutentha kuti chiwunikire ndikulipira kutentha kwagawo lililonse la kutentha munthawi yeniyeni;

14. Njira yogwiritsira ntchito ndi kasamalidwe ka mawu achinsinsi imalepheretsa ogwira ntchito osagwirizana kuti asinthe magawo a ndondomekoyi, ndipo kasamalidwe ka mbiri ya ntchito akhoza kufufuza kusintha kwa magawo a ndondomekoyi, yomwe ili yabwino kuti ipititse patsogolo kasamalidwe.Ikhoza kusunga kutentha komwe kulipo kwa wogwiritsa ntchito ndi piritsi la kutentha pansi pa zoikamo, ndipo ikhoza kusintha zonse Zosindikiza ndi ma curve;

15. Mawindo ophatikizika owongolera, kusintha kwa makompyuta, kupindika kwa mayeso, kupindika kosindikiza ndi kufalitsa deta zonse ndizosavuta kugwiritsa ntchito, ndipo kapangidwe kake kamakhala kogwirizana ndi anthu.Okonzeka ndi njira zitatu kutentha pamapindikira pa Intaneti kuyezetsa dongosolo, amene angathe kudziwa kwenikweni kutentha pamapindikira chinthu kuwotcherera pa nthawi iliyonse (palibe chifukwa sintha kutentha pamapindikira Tester);

16. Dongosolo lozizira kwambiri lochokera kuukadaulo wapadziko lonse lapansi limatengera kukulitsa kwagalasi-mtundu wapakati komanso kuziziritsa kofulumira, liwiro lozizira limatha kufika 3.5 ~ 6 ° C / sec, ndipo kasamalidwe ndi kothandiza kwambiri;kunja kukakamizidwa kuzirala chipangizo amaonetsetsa crystallization zotsatira za olowa solder (Njira kusankha, muyezo kasinthidwe amakakamizika zachilengedwe kuzirala);

17. Rosin Recovery System: Rosin imayenda molunjika, yomwe ili yabwino kwambiri m'malo ndi kuyeretsa.Mapaipi apadera amagwiritsidwa ntchito potumiza mpweya wotulutsa mpweya, womwe umakhala wopanda ntchito kwa moyo wonse;

18. Kapangidwe kapadera kamene kamayendera mpweya ndi mawonekedwe apadera a waya wotentha, palibe phokoso, palibe kugwedezeka, kutentha kwakukulu, kusiyana kwa kutentha △t pakati pa pansi pa BGA ndi bolodi la PCB ndi laling'ono kwambiri, lomwe limakumana ndi zovuta kwambiri. Zofunikira panjira yopanda chitsogozo, makamaka pazinthu zopanda kutsogolera zomwe zimakhala zovuta kwambiri pakuwotchera.

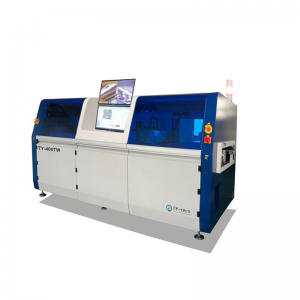

Tsatanetsatane Chithunzi

Zofotokozera

| Chitsanzo | Mtengo wa TYtech 6010 | |

| Heating System | Chiwerengero cha madera otentha | UP 6/PASI 6 |

| Chiwerengero cha madera ozizira | Pamwamba pa 1/PASI 1 | |

| Kutalika kwa madera otentha | 2500MM | |

| Kutentha mode | mpweya wotentha | |

| Njira Yozizirira | Mphamvu mpweya | |

| Conveyor System | Max.Mtengo wapatali wa magawo PCB | 300 mm |

| Mesh lamba m'lifupi | 400 mm | |

| Njira yotumizira | L→R(kapena R→L) | |

| Transmission Net Height | 880 ± 20mm | |

| Mtundu wotumizira | Mesh ndi unyolo | |

| M'lifupi mwake njanji | 0-300 mm | |

| Liwiro la conveyor | 0-1500mm / mphindi | |

| Kutalika kwa gawo | Pamwamba 35mm, pansi 25mm | |

| Auto/Manual Lubrication | muyezo | |

| Njira yopangira hood | Chovala chamagetsi chamoto | |

| Mbali ya njanji yokhazikika | Sitima yakutsogolo yokhazikika (njira: njanji yakumbuyo yokhazikika) | |

| Zigawo zapamwamba | Pamwamba ndi pansi 25mm | |

| Dongosolo lowongolera | Magetsi | 5line 3phase 380V 50/60Hz |

| Mphamvu yoyambira | 18kw pa | |

| Kugwiritsa ntchito mphamvu mwachizolowezi | 4-7KW | |

| Nthawi yofunda | Pafupifupi mphindi 20 | |

| Temp.kuyika range | Kutentha kwa chipinda -300 ℃ | |

| Temp.njira yolamulira | PLC ndi PC | |

| Temp.kuwongolera molondola | ±1℃ | |

| Temp.kusintha kwa PCB | ±2℃ | |

| Kusungirako deta | Sinthani Data ndi malo osungira (80GB) | |

| Nozzle mbale | Aluminium Alloy Plate | |

| Alamu yachilendo | Kutentha kwachilendo.(kutentha kwambiri / kutsika kwambiri.) | |

| Board idatsitsa alarm | Tower kuwala: Yellow-kutentha, Green-yachibadwa, Red-abnormal | |

| General | Dimension(L*W*H) | 3600 × 1100 × 1490mm |

| Kulemera | 900KG | |

| Mtundu | Kompyuta imvi | |