Feature

Features:

1. Using a micro electromagnetic pump tin furnace, the tin wave is high, the flow is large, the wave peak is stable, the solder joint penetration depth is large, and the wetting and soldering power is strong.

2. The periphery of the nozzle and the surface of the solder are protected by nitrogen filling, which can improve the solderability of lead-free solder, reduce the amount of tin slag generated, prevent the nozzle from clogging, and save welding costs and labor costs.

3. High temperature resistance, corrosion resistance and unique nozzle, strong oxidation resistance, good wettability, normal use time can reach 3 months.

4. Automatically detect the solder liquid level to ensure stable wave peaks.

5. It has solder joint slimming function.

6. Comes standard with two CCD cameras to monitor welding status and PCB positioning programming.

Overview of program advantages:

n All in one machine, can accommodate 3 boards or 3 pallet, one in spray flux, one is preheating, another in soldering, get bigger production yield.

n Individual spray flux table & soldering table.

n High soldering quality.

n SMEMA in line connection capable.

n Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,N2 temperature etc, best trace-ability and easy to get repeat soldering quality.

Part1: Software

- All software system developed by company from USA, with our 8 years experience about selective soldering, base on Windows7 system, with good trace-ability.

- Use scanned picture as background for path programming, moving speed, dwell time, empty move speed, Z height , wave height etc all programmed for different solder site.

- Show solder process with live on camera.

- Critical parameters are totally under monitoring by PC software, like temperature, speed, pressure etc.

- Can upgraded to be with auto wave height calibration function, to check & calibrate wave’s height after every certain pcb, so to keep a very good stability of wave.

- About PCB’s menu in soldering machine, all information will be stocked in one file. It will include PCB dimension and picture, used flux type, solder type, solder nozzle type, solder temperature, N2 temperature, motion path and each site’s related wave height and Z height etc. When customer to solder same PCB, they can get full information about how it’s done in history, also easy for trace.

Part2: motion system

- Self design motion table with cast aluminum, lighter weight with quick motion speed.

-

Panasonic servo motor & driver provide stable driving power, with screw pole & linear guild rail for guidance. Precious position, less noise, stable movement.

- With dust proof plate above motion table, so to avoid flux or solder drop to damage ball screw.

Part 3: fluxing system

- Standard equipped with imported jet valve to get precious fluxing result with small flux dot, please note flux solid content should be less than 10%.

- Flux is stocked by PP plastic pressure tank, make sure pressure stable without influenced of amount of flux.

Part 4: Preheat

- At conveyor top & bottm equipped with IR preheating. Position is adjustable.

- Heating ratio is adjustable by PC, from 0 ---100%

Part 5: dual solder pot

- TWO solder pot system with individual temperature control, N2 temperature control, wave height control. All installed in one same table. The distance between two solder pot can be adjusted.

- Solder temperature, N2 temperature, wave height, wave calibration etc all able to set in software.

- Solder pot is made of Ti, not leakage. With cast iron heater outside, robust & quick heat up.

- Solder pot is wired with quick connector. When exchange solder pot without re-wiring required, just plug & play.

- N2 online heating system, to wet the soldering perfectly and reduce the solder dross.

- With solder level checking & alarm.

Part 6: conveyor

- Stepper motor drive for fixed & movable conveyor.

- With stainless steel roller for conveyor, not wearable with long term usage. Also make sure solder nozzle can approach to board’s edge 3mm.

- With PCB clamping system at conveyor.

Detail Image

Specifications

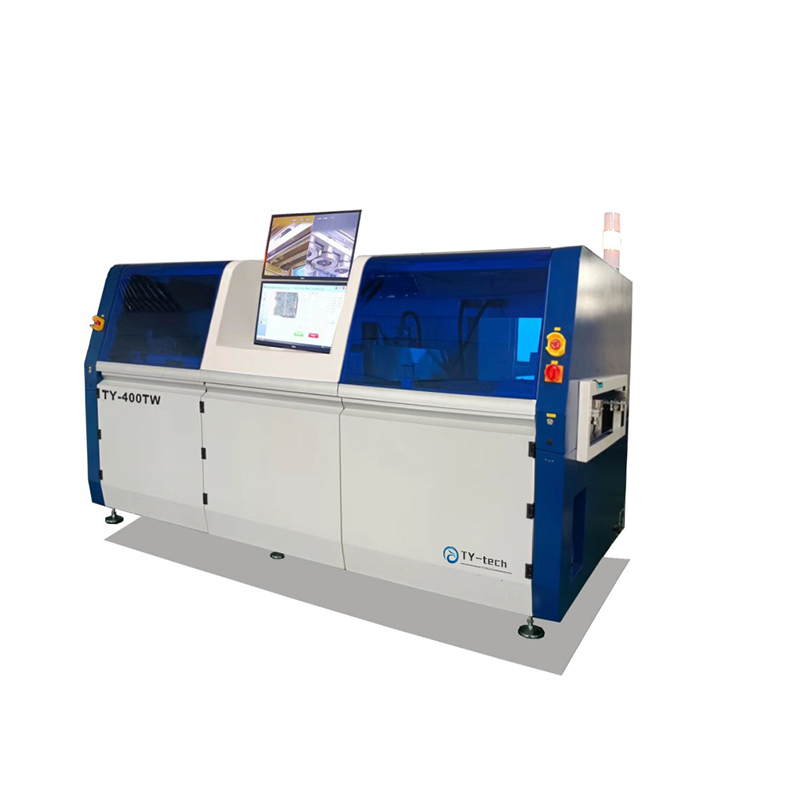

| Model | TY-400TW-2 |

| General | |

| Dimension | L3100 * W1650 * H1650mm |

| General power | 28kw |

| Consumption power | 6--10kw |

| Power supply | Three-phase five-wire system 380V |

| Net weight | 350KG |

| Required air source | 3-5 Bars |

| Required air flow | 8-12L/min |

| Required N2 pressure | 3-4 Bars |

| Required N2 flow | >4 cubic meters/hour |

| Required N2 purity | 》99.998% |

| Required exhausting | Above the spray: 800---1000cbm/h

Above the tin furnace: 600---800cbm/h |

| Carrier or PCB | |

| Carrier | Necessary |

| Max PCB size | L450 * W230MM*2 Note: W is the machine width direction |

| Min carrier size | L450 * W450MM Note: W is the machine width direction |

| Max solder area | L500 * W230MM *2 Note: W is the machine width direction |

| Pcb edge | 3mm or more |

| Controlling & conveyor | |

| Controlling | PLC + controller |

| Conveyor width | 300-600MM |

| Conveyor type | Pin chain conveyor for fluxing & preheating, roller conveyor for soldering |

| Conveyor thick | 1----4mm |

| Conveyor direction | Left to right |

| Conveyor up clearance | 100MM |

| Conveyor bottom clearance | 30MM |

| Conveyor load | <10kg |

| Conveyor rail | Aluminum rail |

| Conveyor height | 900+/-30mm |

| Motion table(fluxing) | |

| Motion axis | X, Y |

| Motion control | Servo control |

| Position accuracy | + / - 0.05 mm |

| Chassis | metal welding |

| Flux management | |

| Flux nozzle | jet valve |

| Nozzle durability | stainless steel |

| Flux tank capacity | 1L |

| Flux tank | pressure tank |

| Preheat | |

| Preheat method | upper & bottom IR heating |

| Heater’s power | 16kw |

| Temperature range | 25--240c degree |

| Motion table(soldering) | |

| Motion axis | X, Y, Z |

| Motion control | servo control |

| Motion motor | Panasonic servo motor |

| Ball screw | Hiwin |

| Position accuracy | + / - 0.05 mm |

| Chassis | Metal welding |

| Solder pot | |

| Standard pot number | 2 |

| Solder pot capacity | 13 kg /pot*2 |

| Solder temperature range | PID |

| Melting time | 60--70 Minutes |

| Max solder temperature | 350 ℃ |

| Solder heater | 1.2kw*2 |

| Solder nozzle | |

| Nozzle dim | customized |

| Material | high carbon alloy |

| Standard equipped nozzle | Standard configuration: 5 pieces/furnace (inner diameter 3mm, 4mm, 5mm, 6mm, 8mm) |

| N2 management | |

| N2 heater | standard equipped |

| Nitrogen PID control N2 temp range | 0 - 350 ℃ |

| N2 consumption | 1-2m3/h/pot total: 4 m3/h |

-

High Quality SMT Selective Soldering Machine TY...

-

SMD Pick And Place Machine With 4 Placement Hea...

-

PCBA Cleaning Machine For SMT Machine Line PCB ...

-

Offline PCBA Router Machine Single Table TY-330

-

China Wholesale Lead Free Reflow Soldering Oven...

-

JT Full-Tunnel Entire Nitrogen Wave Soldering S...