Feature

1. Brand LCD computer + PLC intelligent control system is adopted, with a high temperature control accuracy of ±1°C (if the computer crashes unexpectedly, offline work can be realized without affecting production), ensuring the stability and reliability of the control system;

2. Windows7 operation interface, powerful and easy to operate;

3. The opening of the upper furnace body adopts double electric jacking machinery to ensure safety and reliability;

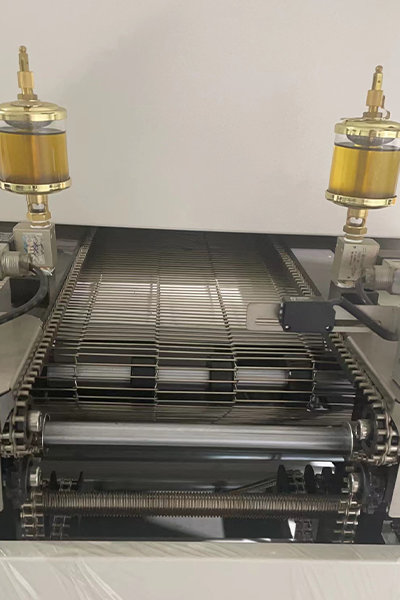

4. Equipped with mesh belt tensioning device, the transportation is stable, no shaking, no deformation, ensuring smooth transportation of PCB;

5. Synchronous guide rail transmission mechanism (can be connected online with the automatic placement machine) to ensure accurate guide rail width adjustment and high service life; (optional guide rail)

6. Automatically control the lubrication system, which can automatically lubricate the transmission chain by setting the refueling time and refueling amount;

7. All heating zones are PID controlled by computer (the temperature zones can be opened separately. The heating can be divided into zones to reduce the starting power);

8. The network/chain transmission is fully closed-loop controlled by the computer, which can meet the simultaneous production of different types of PCBs;

9. With fault sound and light alarm function;

10. Equipped with leakage protector to ensure the safety of operators and control system;

11. Built-in UPS and automatic delay shutdown system to ensure that the PCB and reflow soldering machine will not be damaged when the power is cut off or overheated;

12. Adopt HELLER hot air circulation heating method, high-efficiency pressurized acceleration air duct, greatly increase the flow of circulating hot air, rapid temperature rise (about 10 minutes), high thermal compensation efficiency, and high-temperature welding and curing;

13. The temperature zone is equipped with an independent temperature sensing sensor to monitor and compensate the temperature balance of each temperature zone in real time;

14. The operating system with password management prevents unrelated personnel from changing the process parameters, and the operation record management can trace the change process of the process parameters, which is convenient for improving management. It can store the user's existing temperature speed setting and the temperature curve under the setting, and can change all Print data and curves;

15. Integrated control window, computer switch, test curve, print curve and data transmission are all easy to operate, and the design is humanized. Equipped with a three-channel temperature curve online testing system, which can detect the actual temperature curve of the welding object at any time (no need to configure a temperature curve tester);

16. The rapid cooling system from international technology adopts magnifying glass-type centralized and efficient rapid cooling, the cooling speed can reach 3.5~6°C/sec, and the management is very convenient; the external forced cooling device ensures the crystallization effect of solder joints (Option optional, the standard configuration is forced natural air cooling);

17. Rosin recovery system: Rosin flows in a directional manner, which is very convenient for replacement and cleaning. Special pipelines are used to transmit exhaust gas, which is maintenance-free for life;

18. Special pressurized air transport structure and special-shaped heating wire design, no noise, no vibration, high heat exchange rate, the temperature difference △t between the bottom of the BGA and the PCB board is extremely small, which best meets the strict requirements of the lead-free process , especially for lead-free products with high difficulty soldering requirements.

Detail Image

Specifications

| Model |

TYtech 6010 |

|

| Heating System | Number of heating zones | UP 6/BOTTOM 6 |

| Number of cooling zones | Up 1/BOTTOM 1 | |

| Length of heating zones | 2500MM | |

| Heating mode | hot air | |

| Cooling Mode | Force air | |

| Conveyor System | Max. Width of PCB | 300mm |

| Mesh belt width | 400mm | |

| Transmission Direction | L→R(or R→L) | |

| Transmission Net Height | 880±20mm | |

| Transmission type | Mesh and chain | |

| Range of rail width | 0-300mm | |

| Conveyor speed | 0-1500mm/min | |

| The component height | Top 35mm ,bottom 25mm | |

| Auto/manual Lubrication | standard | |

| Upper hood method | Auto electric hood | |

| Fixed rail side | Front rail fixed(option: rear rail fixed) | |

| Components high | Top and bottom 25mm | |

| Control system | Power supply | 5line 3phase 380V 50/60Hz |

| Starting power | 18kw | |

| Normal power consumption | 4-7KW | |

| Warming time | About 20 mins | |

| Temp. setting range | Room temperature-300℃ | |

| Temp. control method | PLC & PC | |

| Temp. control precision | ±1℃ | |

| Temp. deviation on PCB | ±2℃ | |

| Data storage | Process Data and status storage(80GB) | |

| Nozzle plate | Aluminum Alloy Plate | |

| Abnormal Alarm | Abnormal temperature. (extra-high/extra-low temp.) | |

| Board dropped alarm | Tower light: Yellow-warming, Green-normal, Red-abnormal | |

| General | Dimension(L*W*H) | 3600×1100×1490mm |

| Weight | 900KG | |

| Color | Computer gray | |