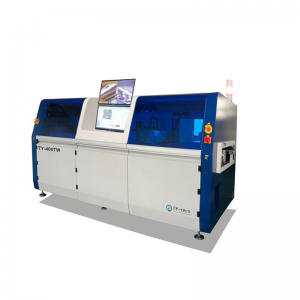

Tungamira Yemahara Inopisa Mhepo Inoyerera Ovheni TY-1220

Nhanganyaya:

1. Iyo brand komputa uye Nokia PLC yakangwara yekudzora sisitimu, yakakwirira chaiyo tembiricha kutonga iri ± 1-2 ℃ (kana mutsaona yekombuta, inogona kuona basa rekunze, haikanganisi kugadzirwa) uye kuve nechokwadi kuti iyo control system iri yakagadzikana uye yakavimbika;

2. Windows XP inoshandisa interface ine simba uye nyore kushanda.

3.Kuitira kuve nechokwadi chekuchengetedza uye kuvimbika, cylinder body inogona kusimudzwa kumusoro.

4. Mudziyo wakashongedzerwa mesh bhandi, kutakura zvakanaka, hapana kuzununguka uye hapana deformation, inova nechokwadi chekufambisa kwePCB.Synchronous gwara rekufambisa nzira uye otomatiki SMT muchina wepamhepo yekubatanidza inova nechokwadi chekuti inotungamira inogadziriswa yakafara chaizvo uye hupenyu hwesevhisi.

5. Automatic control lubrication system uye otomatiki lubrication kutapurirana cheni.

6.Yese inodziya nzvimbo yekudzora nekombuta PID (yepamusoro tembiricha zone uye yakadzika tembiricha zone kuitiswa yakazvimirira tembiricha kutonga, zvinoreva kuti inogona kugovera tembiricha yenzvimbo yekupisa, kuitira kuderedza kutanga simba)

7. Mambure / cheni kutapurirana nekombuta kuita iyo yese yakavharwa loop control, iyo inogona kusangana nemhando dzakasiyana dzePCB kugadzirwa panguva imwe chete.

8. Nekukanganisa inzwi uye chiedza aramu basa.

9. Nekudzivirira kwekudzivirira, chengetedza kuti vashandi vekushanda uye kudzora system kuchengetedza.

10.Iyo yakavakirwa-mukati UPS uye otomatiki kunonoka kudzima system garandi yekudzorera welder musimba kana overheat haina kukuvadza PCB uye muchina.

11. Nyika yeGerman ERSA inotungamira microcirculation kudziyisa modhi, uye yekumusoro uye yakaderera yakazvimirira mhepo microcirculation system, tembiricha kufanana uye kupisa kwemoto muripo wakanyanya kushanda, yakakwirira inoshanda supercharged accelerated air duct, inovandudza zvakanyanya kutenderera kwemhepo inopisa, kupisa kupisa nekukurumidza (pamusoro pe. maminitsi makumi maviri), muripo wekupisa kwekushanda kwepamusoro, kupisa kwekushisa kwepamusoro uye kurapa;

12. Yepamusoro uye yakadzikira tembiricha yega yega ine yakazvimirira tembiricha inductive sensor, chaiyo-nguva yekutarisa uye muripo yega yega tembiricha chiyero;

13. Iva nepassword kutonga kweiyo inoshanda sisitimu, kudzivirira iyo isingakodzeri shanduko yevashandi kune maitiro paramita, oparesheni marekodhi manejimendi traceability process paramita shanduko, kuvandudza manejimendi zviri nyore.Yekuchengetedza mushandisi aripo tembiricha yekumhanyisa kuseta uye Zvirongwa zvetembiricha curve, uye inogona kushandiswa kune ese data uye curve kudhinda;

14. Yakabatanidzwa inodzora hwindo, switch yekombuta, test curve, print curve uye data transmission zviri nyore kushanda, humanized dhizaini.Yakashongedzerwa nematatu-channel tembiricha curve online yekuyedza system, inogona chero nguva yekutarisa welding zvinhu neiyo chaiyo tembiricha curve (pasina imwe match tembiricha curve tester);

15. Kubva kune tekinoroji yepasirese yekukurumidza kutonhora sisitimu, shandisa yekukudza girazi mhando inoshanda nekukurumidza kutonhora, kutonhora kumhanya kunogona kusvika 3.5 ~ 6 ℃/ SEC, manejimendi ari nyore kwazvo;Iyo yekunze yekumanikidza yekutonhodza mudziyo, ive nechokwadi chekuti gwapa rekristaro mhedzisiro (Sarudzo yakasarudzwa zvinhu, iyo yakajairwa gadziriso yekumanikidza echisikigo kutonhora kwemhepo).

Tsanangudzo:

| Model | TY-Tech 1220 | ||

| Heating System | Nhamba yenzvimbo dzekupisa | Kumusoro 12/ pasi 12 | |

| Nhamba yenzvimbo dzekutonhodza | 2 | ||

| Kureba kwenzvimbo dzekudziya | 4640mm | ||

| Heating mode | Hot air | ||

| Cooling Mode | Kutonhodzwa kwemhepo | ||

| Exhaust Volume | 10m³/min * 2 kupera simba | ||

| Conveyor System | Max.Kufara kwePCB | 400mm | |

| Mesh bhandi upamhi | 450mm | ||

| Transmission Direction | L→R(sarudzo: R→L) | ||

| Transmission Net Height | 900±20mm | ||

| Transmission type | Mesh uye cheni | ||

| Range yehupamhi hwenjanji | 400mm | ||

| Conveyor speed | 0-2000mm/min | ||

| Auto/manual Lubrication | Standard | ||

| Fixed njanji divi | Front njanji yakagadziriswa (sarudzo: njanji yekumashure yakagadziriswa) | ||

| Zvikamu zvakakwirira | Pamusoro uye pasi 25mm | ||

| Kudzora system | Magetsi | 5 mutsetse 3 chikamu 380V 50/60HZ | |

| Total power | 48KW | ||

| Kazhinji kushandiswa kwesimba | 10-12KW | ||

| Nguva yekudziya | 20 mins | ||

| Temp.setting range | Kubva mukamuri temp.Kusvika ku300 ℃ | ||

| Temp.control method | PID yekuvhara loop control & SSR kutyaira | ||

| Temp.kudzora nemazvo | ±1℃ | ||

| Temp.kutsauka paPCB | ±2℃ | ||

| Kuchengetedza data | Gadzirisa Dhata uye mamiriro ekuchengetedza (80GB) | ||

| Nozzle ndiro | Aluminium Alloy Plate | ||

| Abnormal Alarm | Tembiricha isina kujairika (yakawedzera-yakakwirira/yakawedzera-yakadzika tembiricha) | ||

| Board yakadonhedza alarm | Tower light:Yero-kudziya,Green-yakajairika, Tsvuku-zvisina kujairika | ||

| General | Dimension(L*W*H) | 6300*1320*1490mm | |

| Kurema | 2600kg | ||

| Color | Computer grey | ||

Keywords:SMT Reflow oven, Lead free Reflow Oven, High end reflow oven, Reflow Soldering Oven, Reflow Oven Manufacture, Led Reflow Oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Lane Reflow oven, China Reflow Oven, PCB Soldering Machine.

FAQ:

Q. Chii chako MOQ chinodiwa pamushini?

A. 1 set moq zvinodiwa pamushini.

Q. Aka ndekekutanga kushandisa muchina werudzi urwu, uri nyore kushanda here?

A: Kune bhuku reChirungu kana vhidhiyo yekutungamira inokuratidza mashandisiro emuchina.

Mubvunzo: Kana muchina wacho uine dambudziko mushure mekunge taugamuchira, tingaita sei?

A: Injiniya yedu ichabatsira kuigadzirisa kutanga, uye zvikamu zvemahara zvinotumira kwauri munguva yemuchina waranti.

Mubvunzo: Iwe unopa chero waranti yemuchina here?

A: Hongu 1 gore waranti ichapihwa kumushini.

Q: Ndingaisa sei odha newe?

A: Unogona kusvika kwatiri neemail, whatsapp, wechat uye kusimbisa mutengo wekupedzisira, nzira yekutumira uye nguva yekubhadhara, tobva takutumira invoice yeproforma ine ruzivo rwekubhengi kwauri.