Reflow soldering ndiyo inonyanya kushandiswa nzira yekubatanidza pamusoro pegomo zvinhu kune akadhindwa edunhu mabhodhi (PCBs).Chinangwa chemaitiro acho ndechekugadzira majoini anogamuchirika ekutengesa nekutanga pre-kupisa zvikamu / PCB / solder paste uyezve kunyungudutsa solder pasina kukuvadza nekupisa.

Izvo zvakakosha zvinotungamira kune inoshanda reflow soldering maitiro ndeaya anotevera:

- Inokodzera muchina

- Inogamuchirwa reflow profile

- PCB/chikamu footprint Dhizaini

- Kunyatsodhindwa PCB uchishandisa stencil yakagadzirwa zvakanaka

- Kudzokororwa kuiswa kwepamusoro-soro zvikamu

- Yakanaka mhando PCB, zvikamu uye solder paste

Inokodzera Machine

Kune mhando dzakasiyana dze reflow soldering muchina unowanikwa zvichienderana neinodiwa mutsara kumhanya uye dhizaini / zvinhu zvePCB maassemblies kuti agadziriswe.Ovheni yakasarudzwa inoda kuve yehukuru hwakakodzera kubata mwero wekugadzira wepiki uye nzvimbo yemidziyo.

Kumhanya kwemutsara kunogona kuverengerwa sezvinoratidzwa pazasi: -

Kumhanya kwemutsara (zvishoma) =Mabhodhi paminiti x Kureba pabhodhi

Load Factor (nzvimbo pakati pemapuranga)

Izvo zvakakosha kuti titarise kudzokorora kwemaitiro uye saka iyo 'Load Factor' inowanzotsanangurwa nemugadziri wemuchina, kuverenga kunoratidzwa pazasi:

Kuti ukwanise kusarudza saizi chaiyo reflow ovheni kukurumidza kwekuita (kunotsanangurwa pazasi) kunofanirwa kunge kwakakura kudarika kudiki kwakaverengerwa mutsara kumhanya.

Process speed =Ovheni kamuri kudziyisa kureba

Process yekugara nguva

Pazasi pane muenzaniso wekuverenga kumisa saizi chaiyo yeovheni: -

SMT assembler inoda kugadzira 8-inch board pamwero we180 paawa.Iyo solder paste mugadziri anokurudzira 4 maminetsi, matatu nhanho mbiri.Inguva yakadii hovhoni yandinofanira kugadzira mabhodhi pakubuda uku?

Mabhodhi paminiti = 3 (180/awa)

Kureba pabhodhi = 8 inches

Load Factor = 0.8 (2-inch nzvimbo pakati pemapuranga)

Process Kugara Nguva = 4 maminitsi

Kuverenga Kumhanya Kwemutsetse:(3 mapuranga/miniti) x (8 inches/bhodhi)

0.8

Kumhanya kwemutsara = 30 inches/miniti

Naizvozvo, ovheni yereflow inofanira kunge iine kukurumidza kukurumidza kweinenge 30 inches paminiti.

Sarudza hurefu hwekamuri yekudziya ne process speed equation:

30 mu/min =Ovheni kamuri kudziyisa kureba

4 maminitsi

Hurefu hwakapisa huni = 120 inches (10 tsoka)

Ziva kuti hurefu hwehovhoni huchapfuura 10 tsoka kusanganisira yekutonhora chikamu uye conveyor kurodha zvikamu.Iko kuverenga ndeyeKUPISWA KUREREVA - KWETE KWEOVEN LENGTH.

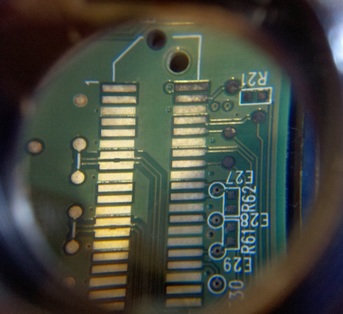

1. Conveyor type - Zvinogoneka kusarudza muchina une mesh conveyor asi kazhinji madhiri emupendero anotsanangurwa kuti ovheni ishande mumutsara uye inokwanisa kugadzira magungano ane mativi maviri.Pamusoro pemupendero mutakuri wepakati-bhodhi-rutsigiro kazhinji inosanganisirwa kumisa PCB kubva mukudonha panguva yekuyerera kwekuita - ona pazasi.Paunenge uchigadzira maviri mativi magungano uchishandisa kumucheto conveyor system kutarisirwa kunofanirwa kutorwa kuti isakanganise zvikamu zviri pasi.

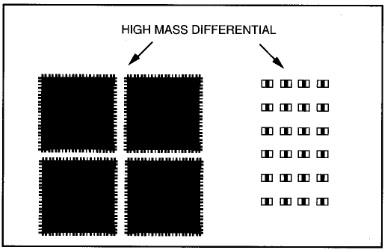

2. Yakavharwa loop control yekumhanyisa mafeni econvection - Kune mamwe mapeji epamusoro epamusoro seSOD323 (ona kuisa) ayo ane nzvimbo diki yekusangana kusvika kuhuwandu hwehuwandu iyo inogona kukanganiswa panguva yekuyerera.Yakavharwa loop yekumhanyisa kudzora yevatevedzeri vegungano isarudzo inokurudzirwa kumagungano anoshandisa zvikamu zvakadaro.

3. Automatic control of conveyor and center-board-support widths - Mimwe michina ine manual hupamhi gadziriso asi kana paine akawanda akasiyana maassembly kuti agadziriswe nekusiyana PCB hupamhi saka iyi sarudzo inokurudzirwa kuchengetedza maitiro anoenderana.

Inogamuchirwa Reflow Profile

- Mhando ye solder paste

- PCB zvinhu

- PCB ukobvu

- Nhamba yezvikamu

- Kuwanda kwemhangura mukati mePCB

- Nhamba yezvikamu zvekukwira pamusoro

- Mhando yezvikamu zvekukwira pamusoro

Kuti ugadzire reflow profile thermocouples akabatana nesample assembly (kazhinji ine tembiricha solder) munzvimbo dzinoverengeka kuyera huwandu hwetembiricha mhiri kwePCB.Zvinokurudzirwa kuve neinenge imwe thermocouple iri padhi yakananga kumucheto kwePCB uye imwe thermocouple iri pane padhi yakananga pakati pePCB.Zvakanakisa mamwe thermocouples anofanirwa kushandiswa kuyera huwandu hwakazara hwetembiricha mhiri kwePCB - inozivikanwa se'Delta T'.

Mukati meyakajairwa reflow solder profile pane kazhinji matanho mana - Preheat, soak, reflow uye kutonhora.Chinangwa chikuru chiri chekuendesa kupisa kwakakwana mugungano kuti rinyungudutse solder uye kugadzira majoini ekutengesa pasina kukuvadza kune zvikamu kana PCB.

Preheat- Munguva iyi zvikamu, PCB uye solder zvese zvinopiswa kune yakatarwa soak kana kugara tembiricha uchichenjerera kuti usakurumidza kupisa (kazhinji haipfuuri 2ºC/sekondi - tarisa solder paste datasheet).Kupisa nekukasira kunogona kukonzera kuremara kwakadai sezvikamu kutsemuka uye solder paste kuti splatter ichikonzera solder mabhora panguva yekuyerera.

Soak- Chinangwa chechikamu ichi ndechekuona kuti zvikamu zvese zviri kusvika kune tembiricha inodiwa usati wapinda padanho rekuyerera.Soak inowanzotora pakati pemasekonzi 60 ne120 zvichienderana ne 'kusiyana kukuru' kwegungano uye mhando dzezvikamu zviripo.Kunyanya kushanda kwekupisa kwekushisa panguva yekunyorova nguva shoma inodiwa.

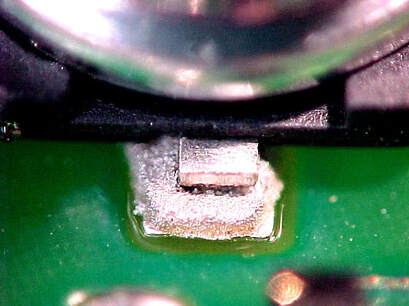

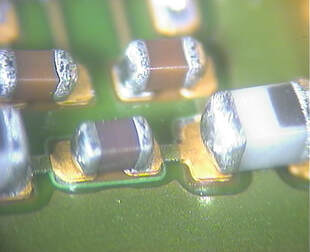

A common soldering defect mushure me reflow ndiko kuumbwa kwe mid-chip solder balls/beads sezvinoonekwa pazasi.Mhinduro yekukanganisika uku ndeyekugadzirisa stencil dhizaini -mamwe mashoko anogona kuonekwa pano.

Kutonhora- Iri rinongova danho panguva iyo gungano rinotonhodzwa asi zvakakosha kuti usatonhodze gungano nekukurumidza - kazhinji mwero unokurudzirwa wekutonhora haufanire kudarika 3ºC/sekondi.

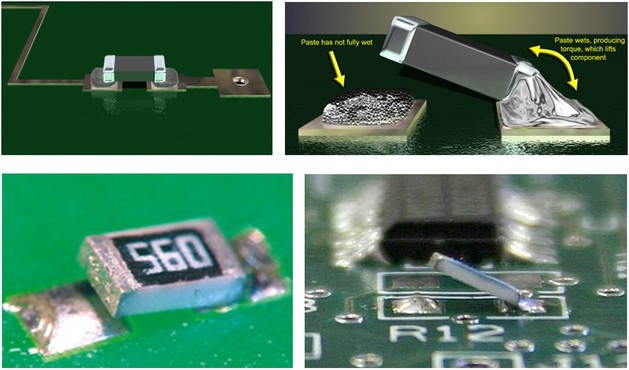

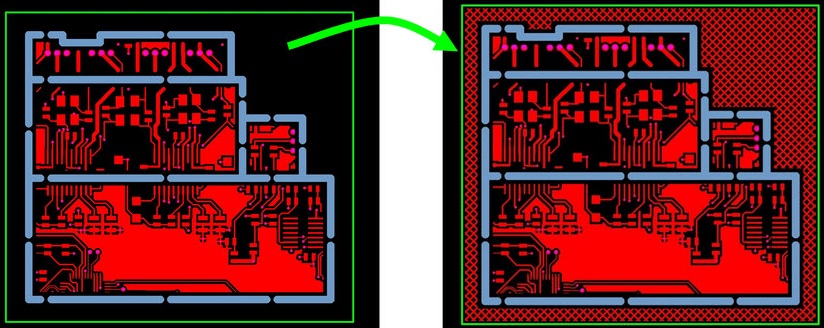

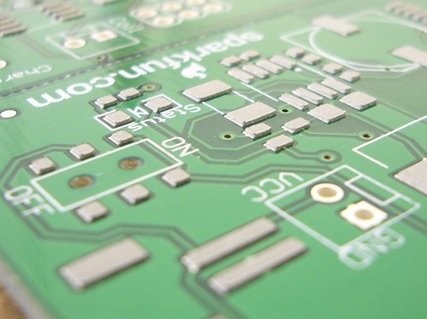

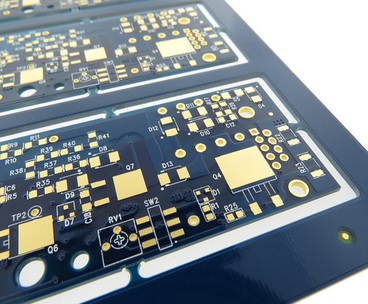

PCB/Component Footprint Dhizaini

Kunyatsodhindwa PCB uchishandisa stencil yakagadzirwa zvakanaka

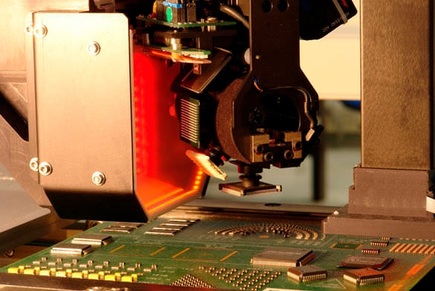

Kudzokororwa kuiswa kwepamusoro-soro zvikamu

Zvirongwa zvekuisa zvikamu zvinogona kugadzirwa uchishandisa pick nekuisa michina asi maitiro aya haana kururama sekutora ruzivo rwecentroid kubva kuPCB Gerber data.Kazhinji iyi data yecentroid inotumirwa kunze kubva kuPCB dhizaini software asi imwe nguva haisi kuwanikwa uye saka iyosevhisi yekugadzira iyo centroid faira kubva kuGerber data inopihwa neSurface Mount process.

Michina yese yekuisa michina ichave ne 'Placement Accuracy' inotsanangurwa senge:-

35um (QFPs) kusvika 60um (chips) @ 3 sigma

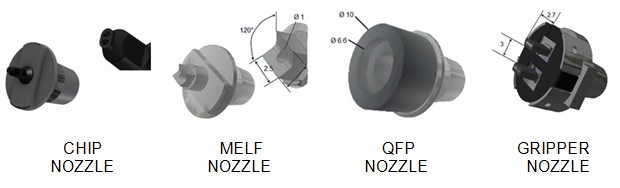

Izvo zvakakoshawo kuti muromo wakakodzera usarudzwe kuti rudzi rwechikamu chiiswe - huwandu hweakasiyana echikamu chekuisa nozzles anogona kuonekwa pazasi:-

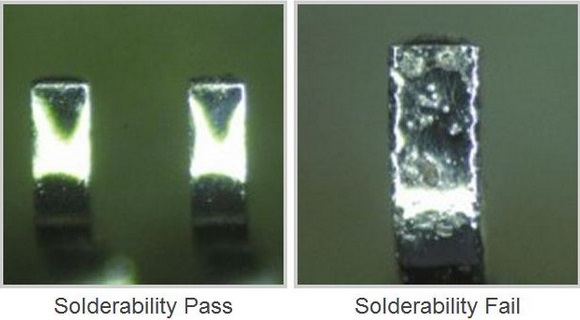

Yakanaka mhando PCB, zvikamu uye solder paste

Nguva yekutumira: Jun-14-2022