Feature

Features:

1. Uchishandisa micro electromagnetic pump tin furnace, iyo tini wave yakakwira, kuyerera kwakakura, iyo wave peak yakagadzikana, iyo solder yekubatanidza yekupinda yakadzika yakakura, uye kunyorova uye solder simba rakasimba.

2. Periphery yemhino nepamusoro pesolder inodzivirirwa nenitrogen kuzadza, iyo inogona kuvandudza kutengesa-isina lead solder, kuderedza huwandu hwemarata anogadzirwa, kudzivirira muromo kubva pakuvharika, uye kuchengetedza mutengo wewelding uye kushanda. mari.

3. High tembiricha kuramba, ngura kuramba uye yakasarudzika nozzle, yakasimba oxidation kuramba, yakanaka wettability, yakajairika kushandisa nguva inogona kusvika 3 mwedzi.

4. Ziva otomatiki chiyero chemvura inotengeswa kuti ive nechokwadi chekugadzikana kwemafungu epamusoro.

5. Iine solder joint slimming basa.

6. Inouya yakajairwa nemakamera maviri eCCD kuti atarise chimiro chewelding uye PCB yekumisikidza hurongwa.

Mhedziso yezvakanakira chirongwa:

n Zvese mumushini mumwe, zvinogonaaccommodate3 mapuranga kana3 pallet, imwe iri muspray flux, imwe irikupisa, imwe mu soldering, kuwana goho rakakura rekugadzira.

n Yega yakapfapfaidza flux tafura & solder tafura.

n High soldering quality.

n SMEMA mumutsara yekubatanidza inokwanisa.

n Full PC kutonga.Ese ma paramita anogona kuseta muPC uye akachengetwa kuPCB menyu, senge nzira inofamba, tembiricha yekutengesa, flux mhando, solder mhando,N2tembiricha etc, yakanyanya kunaka-kugona uye nyore kuwana inodzokorora solder mhando.

Chikamu 1: Software

- Yese software system yakagadziridzwa nekambani kubva kuUSA, iine makore 8 ruzivo nezve yakasarudzika soldering, yakavakirwa paWindows7 system, ine yakanaka yekutevera-kugona.

- Shandisa pikicha yakaongororwa semashure ekuronga nzira, kukurumidza kufamba, nguva yekugara, isina chinhu kumhanya, Z urefu, wave kureba nezvimwe zvese zvakagadzirirwa nzvimbo dzakasiyana dzekutengesa.

- Ratidza solder process ine live pane kamera.

- Akakosha ma paramita ari pasi pekutariswa nePC software, senge tembiricha, kumhanya, kudzvanywa nezvimwe.

- Inogona kukwidziridzwa kuve neauto wave kureba calibration basa, kutarisa & calibrate wave's kureba pashure ose imwe pcb, saka kuchengeta yakanaka chaizvo kugadzikana kwemafungu.

- Pamusoro pePCB's menyu mumuchina wekutengesa, ruzivo rwese ruchaiswa mufaira rimwe chete.Ichasanganisira PCB dimension uye mufananidzo, yakashandiswa flux mhando, solder mhando, solder nozzle mhando, solder tembiricha, N2 tembiricha, inofamba nzira uye yega saiti.'s ane chokuita masaisai kureba uye Z urefu etc. Kana mutengi solder zvakafanana PCB, vanogona kuwana mashoko akazara sei'zvakaitwa munhoroondo, zvakare zviri nyore kutsvaga.

Chikamu 2: hurongwa hwekufamba

- Self dhizaini inofamba tafura ine yakakandwa aluminium, yakareruka huremu nekukasira kufamba.

-

Panasonic servo mota & mutyairi inopa yakagadzikana simba rekutyaira, ine screw pole & linear guild njanji yekutungamira.Nzvimbo yakakosha, ruzha rushoma, kufamba kwakagadzikana.

- Iine guruva proof plate pamusoro petafura inofamba, saka kudzivirira flux kana solder kudonha kukuvadza bhora sikuru.

Chikamu 3: fluxing system

- Yakashongedzerwa neiyo jet vharuvhu inotengeswa kunze kwenyika kuti uwane yakakosha yekuyerera mhedzisiro ine diki flux dot, ndapota cherechedza flux yakasimba yemukati inofanira kunge iri pasi pegumi%.

- Flux yakarongedzerwa nePP epurasitiki yekumanikidza tangi, ita shuwa kusimba kugadzikana pasina kufurirwa huwandu hwekuyerera.

Chikamu 4: Preheat

- Paconveyor pamusoro & bottm yakashongedzerwa neIR preheating.Position inochinjika.

- Kupisa chiyero chinogadziriswa nePC, kubva ku0 ---100%

Chikamu 5: mbiri solder poto

- PIRIsolder poto system ine yega tembiricha control, N2 tembiricha kutonga, wave kureba kutonga.Yese yakaiswa mune imwechete tafura.Nharaunda pakati pehari mbiri solder inogona kugadziriswa.

- Solder tembiricha, N2 tembiricha, wave kureba, wave calibration nezvimwe zvese zvinokwanisa kuseta musoftware.

- Solder poto inogadzirwa neTi, kwete kuvuza.Iine heater yesimbi kunze, yakasimba & inokurumidza kupisa.

- Solder poto ine tambo ine chinongedzo chinokurumidza.Kana uchichinjana solder poto pasina kudzokorora wiring inodiwa, ingo plug & tamba.

- N2 yepamhepo yekudziya sisitimu, kunyorovesa solder zvakakwana uye kuderedza marara ekutengesa.

- Iine solder level yekutarisa & alarm.

Chikamu 6: conveyor

- Stepper mota dhiraivha yeyakagadziriswa & inotakurika conveyor.

- Iine Stainless simbi roller ye conveyor, isingapfeki nekushandiswa kwenguva refu.Zvakare ita shuwa kuti solder nozzle inogona kusvika pabhodhi's kumucheto 3mm.

- NePCB clamping system pane conveyor.

Detail Image

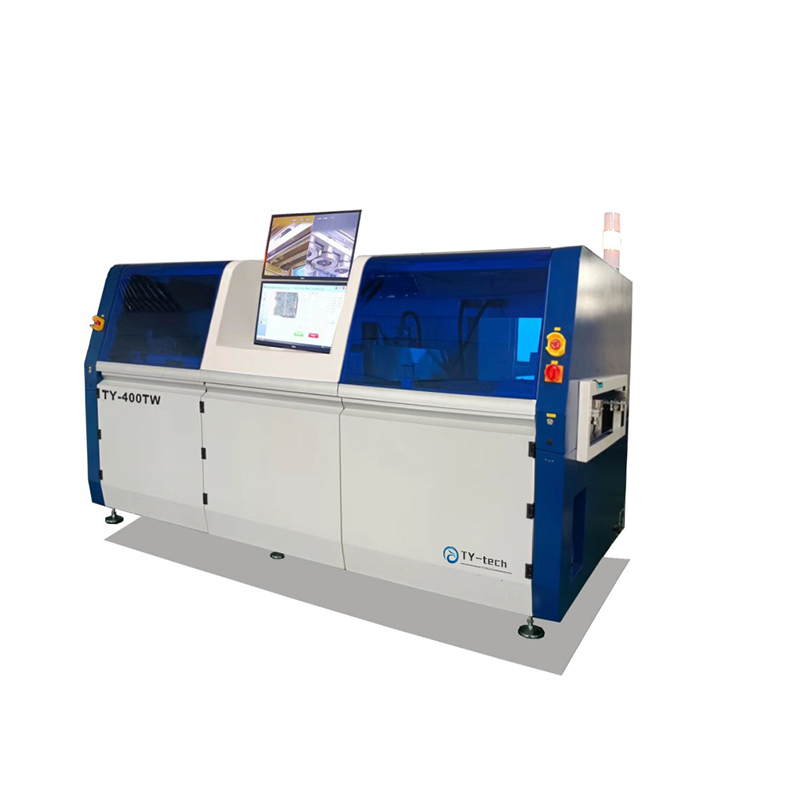

Zvinotsanangurwa

| Model | TY-400TW-2 |

| General | |

| Dimension | L3100 * W1650 * H1650mm |

| General simba | 28kw |

| Kushandisa simba | 6--10kw |

| Magetsi | Nhatu-chikamu cheshanu-waya system 380V |

| Net uremu | 350KG |

| Inodiwa mweya source | 3-5 Mabhawa |

| Kuyerera kwemhepo kunodiwa | 8-12L/min |

| Inodiwa N2 pressure | 3-4 Bhara |

| Inodiwa N2 kuyerera | > 4 cubic metres / awa |

| Inodiwa N2 kuchena | 》99.998% |

| Kunodiwa kupera simba | Pamusoro pekupfapfaidza: 800---1000cbm/h Pamusoro pevira rerata: 600---800cbm/h |

| Cmutakuri kana PCB | |

| Mutakuri | Necessary |

| Yakanyanya PCB saizi | L450 * W230MM*2 Cherechedza: W ndiyo nzira yehupamhi hwemuchina |

| Min mutakuri saizi | L450 * W450MM Cherechedza: W ndiyo nzira yehupamhi hwemuchina |

| Max solder nzvimbo | L500 * W230MM * 2 Cherechedza: W ndiyo nzira yehupamhi hwemuchina |

| Pcb kumucheto | 3mm kana kupfuura |

| Controlling & conveyor | |

| Kudzora | PLC + controller |

| Conveyor width | 300-600MM |

| Conveyor type | Pini cheni conveyor yekugezesa & preheating, roller conveyor ye soldering |

| Conveyor gobvu | 1----4mm |

| Conveyor direction | Kuruboshwe kuenda kurudyi |

| Conveyor up clearance | 100MM |

| Conveyor pasi clearance | 30MM |

| Conveyor load | <10kg |

| Conveyor njanji | Aluminium njanji |

| Conveyor urefu | 900+/-30mm |

| Motion table(kuyerera) | |

| Motion axis | X, Y |

| Motion control | Servo control |

| Kururama kwenzvimbo | +/ - 0.05 mm |

| Chassis | metal welding |

| Flux manejimendi | |

| Flux nozzle | jet valve |

| Nozzle durability | simbi isina ngura |

| Flux tank kugona | 1L |

| Flux tank | pressure tank |

| Preheat | |

| Preheat nzira | kumusoro & pasi IR kudziyisa |

| Simba reheater | 16kw |

| Tembiricha range | 25--240c dhigirii |

| Motion tafura (soldering) | |

| Motion axis | X, Y, Z |

| Motion control | servo control |

| Motion mota | Panasonic servo mota |

| Ball screw | Hiwin |

| Kururama kwenzvimbo | +/ - 0.05 mm |

| Chassis | Metal welding |

| Spoto yakura | |

| Nhamba yepoto yakajairika | 2 |

| Solder poto kugona | 13kg/poto*2 |

| Solder tembiricha range | PID |

| Nguva yekunyunguduka | 60--70 Maminitsi |

| Max solder tembiricha | 350 ℃ |

| Solder hita | 1.2kw*2 |

| Smuromo mukuru | |

| Nozzle dim | customized |

| Material | high carbon alloy |

| Standard akashongedzerwa nozzle | Kugadziriswa kwakajairwa: 5 zvidimbu / vira (mukati dhayamita 3mm, 4mm, 5mm, 6mm, 8mm) |

| N2 manejimendi | |

| N2 heater | mwero wakashongedzerwa |

| Nitrogen PID inodzora N2 temp renji | 0 - 350 ℃ |

| N2 kushandiswa | 1-2m3/h/hari yose: 4 m3/h |