Muuqaal

1. Mashiinka kormeerka mesh birta ee si buuxda otomaatig ah u ah waa aalad wax lagu cabbiro oo adeegsata tignoolajiyada aqoonsiga sawirka tooska ah si ay u ururiso cabbirrada sida cabbirka mesh mesh birta, booska, iyo gidaarka daloolka, oo barbar dhigaya kala duwanaanshaha khaladka iyo qiimaha tixraaca ee lagu dejiyay barnaamijka lagu go'aaminayo in furitaanka mesh birta uu buuxiyo shuruudaha.

2. Habka soo jireenka ah ee baadhitaanka buuggu ma dammaanad qaadi karo saxnaanta kormeerka, si sax ah uma cabbiri karo oo is barbardhigi karo, mana laha diiwaan xog iyo isbarbardhigga falanqaynta.Suurtagal ma aha in la sameeyo cilmi baaris sax ah oo ku saabsan saameynta daaweynta mesh mesh kala duwan ee habka daawaynta tayada inta lagu jiro isticmaalka;

3. Qalabku waa sahlan yahay in la shaqeeyo, habka kormeerkuna si buuxda ayuu otomaatig ah u yahay, taas oo aan si weyn u hagaajinaynin saxnaanta iyo xawaaraha ogaanshaha, laakiin sidoo kale waxay ka fogaanaysaa arrimaha xukunka bini'aadamka, bixinta xogta tooska ah iyo ujeeddooyinka qiyaasta ee lagu qiimeeyo tayada mesh birta;

4. Inta badan meshes birta cusub, cabbir oo qiimee saxnaanta iyo caqli-galnimada mesh mesh birta, oo la soco tayada meshes birta ee la isticmaalo, horay u soo ogow dhibaatooyinka tayada leh, kana ilaali dhibaatooyinka habka dufcadda ay keento tayada mesh birta;

5. Tijaabo toos ah oo diiwangeli, kaydi warbixinnada tijaabada, oo la soco isbeddelada saxsanaanta mesh birta;

6. Hubi oo la soco dhumucda mesh ee talaabada iyo meshes birta caadiga ah si aad u hubiso tayada mesh birta alaabta soo gasha iyo saxnaanta habka;

7. Isticmaal PCB GERBER iyo birta mesh GERBER\CAD faylasha, iwm

8. Hagaajinta awooda xakamaynta iswada, kahortaga wakhtiga, hel, oo xakamaysa dhibaatooyinka tayada iyo waxtarka leh ee ay sababaan dhibaatooyinka mesh birta;

9. Hagaajinta habka furitaanka mesh birta, xalliso dhibaatada mashiinka daabacaadda, oo wanaaji heerka gudbinta ogaanshaha SPI;

10. Si faahfaahsan u diiwaangeli xogta ogaanshaha, oo soo saar noocyo kala duwan oo warbixinno ah si loo hagaajiyo isku xirka falanqaynta habraaca iyo bixinta taageerada horumarinta habka wax soo saarka;

Halabuurka nidaamka

Qaybta ugu weyn: madal marmar ah + qaab dhismeedka gantry tuurista;

Qaybta xakamaynta: guddiga xakamaynta dhaqdhaqaaqa + kumbuyuutarka xakamaynta;

Qaybta wadista: darawalka mootada;

Qaybta guuritaanka: matoor, suunka, birta hagaha, jiididaha;

Qaybta jawaab-celinta: qalabka korontada ku shaqeeya, dareeraha, wareejinta calaamadda, xakamaynta saxan sare;

Qaybta indhaha: kamarad, muraayad, isha iftiinka, xakamaynta isha iftiinka, habka dhaqdhaqaaqa iftiinka;

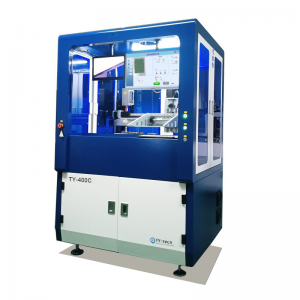

Sawirka Faahfaahin

Tilmaamaha

| Summada | TYtech | |

| Qaabka | TY-SI80 | |

| Test Tilmaamaha | Tijaabiujeedo | Saxnaanta furitaanka Stencil cusub, hubinta tayada, ogaanshaha saamaynta nadiifinta hore ee Stencil, ogaanshaha shayga shisheeye, cabbirka kacsanaanta, isbarbardhigga saxda ah ee Stencil, cabbirka dhumucda; |

| Tijaabi nuxurka | Booska, cabbirka, saxda ah, jidhka shisheeye, kacsanaanta, burka, daloolka; | |

| Boodhka buuxa ee godadka badan | Saxan buuxa kormeer godad badan | |

| Xawaaraha tijaabi | 0.8s/FOV | |

| Saxnaanta kormeerka | Saxnaanta cabbirka | 6.9 μm (la mid ah xallinta FOV: 0.345 μm) |

| Saxnaanta cabbirka aagga | <1%,GR&R<5% | |

| Saxnaanta booska | GR&R<5%,xallinta miisaanka grating ± 1 μm,meelayntasaxsanaanta: ± 10 μm | |

| Soo hel goobta tijaabada | Qaab dhismeedka guuritaanka wuxuu ku dhamaanayaa muunad | |

| Habka meelaynta baabuurka | Muunad joogto ah oo dhammaystiran | |

| Ogaanshaha xiisadda | mitirka saxda ah ee saxda ah, imtixaan kasta oo meelo badan leh;Saxnimada: ± 0.1N.cm, kala duwanaanshaha xiisadda: 0 ~ 50 Isticmaalka saxanka muraayadda ee gudaha qalabka) | |

| Daahfurka ugu yar ee μm | 80 μm * 80 μm | |

| Fogaanta ogaanshaha ugu yar | 80 μm | |

| Daahfurka ugu sarreeya | 10mm * 7mm (by 6.9 μm) | |

| Tirada ugu badan ee furitaanka ogaanshaha | 500000 | |

| Nidaamka indhaha | Kamarada | 5 megapixel camera |

| Lens | 10M muraayad laba-geesood ah oo telecentric indhaha ah | |

| Iftiinka sare | Ring LED iftiinka sare, isha iftiinka LED coaxial | |

| Iftiinka hoose | Iftiinka cagaaran ee tamarta sare leh coaxial LED | |

| Qaraarka | 6.90 μm /pixel | |

| Diirada tooska ah ee leysarka, kala duwan | Shaqooyinka kala duwan ee diiradda laser toos ah | |

| Cabbirka FOV | 16.9mm*13.9mm | |

| Tilmaamaha Stencil | Cabbirka jir ee ugu sarreeya | 813*813*60mm |

| Tirada ugu badan ee cabbirka | 570*570mm | |

| Qeexitaannada Qalabka | Cabirka | 1245*1330*1445mm |

| Miisaanka | <1080KG | |

| Qaab dhismeedka qalabka | Madal marmar ah oo sax ah oo heer sare ah + qaab dhismeedka wax tuurista,Sare-dammaanadda cabbirka saxda ah | |

| Qaab dhismeedka Gantry | Tuur qaabdhismeedka gantry nolosha dheer | |

| Nidaamka gudbinta | Matoorka DC + kontoroolka loop-ka ee xidhan ee shabagga aan lala xidhiidhin | |

| Kombiyuutarka | Nidaamka hawlgalka | Windows 7/10 X64 Edition Professional |

| Kormeeraha kumbuyuutarka | LCD E5 Xeon,32G,2TB+500G,22' LCD | |

| Shaqada software | Habka barnaamijka | Gerber file programming, CAD soo dejinta |

| Waqtiga akhrinta faylka Gerber | 200,000 god gudahood: 5S | |

| Wakhtiga jawaabta shaqada ee faylka Gerber | Gudaha 200,000 godad: 0.3S | |

| Waqtiga barnaamijka | 10000 godad gudahood:2 ilaa 5 daqiiqo | |

| Barnaamijyada khadka tooska ah | Barnaamijyada khadka tooska ah | |

| Barnaamij toos ah | Waxay leedahay barnaamijyo toos ah iyo hawlo barnaamij toos ah oo toos ah | |

| Faylka Gerber | RS-274,RS-274X | |

| Waqtiga beddelka moodeelka | In ka yar 2 daqiiqo, waxaad akhrin kartaa barnaamijka bybarcode/RF | |

| Algorithmamka ugu weyn | Ku xisaabi booska isku-dubbaridka ee sixitaanka MARK Xisaabi booska joometeriga iyo cabbirka faraqa u dhexeeya furitaanka iyo Geberka dhabta ah ee sawirka vector algorithm | |

| Habka tijaabada aaladda | Imtixaanka khadka tooska ah | |

| Tijaabi doorashada waxa ku jira | Nuxurka tijaabada iyo cabirrada waxaa lagu dooran karaa iyadoo loo eegayo cabbirka, nooca, A/R, W/T | |

| Habka tijaabada | Hababka ogaanshaha badan iyo dejinta heerka tijaabada; Qaybaha kala duwan ayaa si gaar ah loo qeexi karaa waxaana lagu tijaabin karaa heerka qaybta,Oo ay ku jiraan bedka, cabbirka, booska, xiisadda, iwm; | |

| Xogta lagu ogaanayo | Keydi magaca barnaamijka, barcode, hawlwadeenka, aagga furitaanka, cabbirka, isku-duwayaasha, dhimista, xogta xiisadda, sawirrada, iwm.; | |

| Xuquuqda isticmaalaha | Heerarka mudnaanta isticmaale waxaa lagu qeexi karaa iyadoo loo eegayo baahida macaamiisha | |

| Ku xidhan nidaamka gudaha ee shirkadda | Taageerada soo dejinta xogta, interface xogta gaarka ah, qaab dhismeedka xogta, habka isgaarsiinta sida loo baahan yahay | |

| Shaqada iskaanka ee Stencil barcode | Akhrinta barnaamijyada iyo maaraynta xogta iyada oo la sawirayo barcode-ka birta ah | |

| Stencil Gerbercontrast PCB Gerberfunction | Isbarbardhigga Stencil GERBER iyo PCB Gerber waxay hubinayaan saxnaanta Stencil GERBER | |

| Taariikhda Stencil | Habka faylku wuxuu diiwaangeliyaa habka tijaabada iyo xogta natiijada, oo wuxuu arki karaa natiijooyinka imtixaanka offline | |

| SPC xogta statisticssoftware | Booska, aagga, cabbirka, falanqaynta xogta SPC, warbixino kooban, warbixinnada saxda ah ee CPK&Grr, jaantusyada kala firdhisan, isugeynta ballaadhinta iyo qandaraasyada, iyo xogta iyo jaantusyada kale; | |

| Xaaladda baahida qalabka | Voltage | AC 220V ± 10% (hal waji), 50/60Hz, 1000VA |

| Hawadacadaadis | Looma baahna cadaadiska hawada | |

| Gariirku ma saameeyaa saxnaanta? | Gariirka Heerka A ee ka hooseeya 50DB ma saameeyo | |

| Adeegga qalabka | Muddada dammaanadda | Hal sano oo dammaanad ah |

| Wareegga hagaajinta qalabka | La saxay hal sano ka dib ama ka dib aaladda moobaylka | |

| Adeegga cusboonaysiinta software | cusboonaysiinta bilaashka ah ee wakhtiga software-ka caadiga ah | |

-

Tayada ugu sareysa ee Siplace TX Pick And Place Machine

-

TYtech Tayada Sare ee Khadka Tooska ah ee Mawjada Xulashada

-

Mashiinka Alxanka Mawjada Mini Dual Wave Alxan...

-

SMT Semi Auto Stencil Solder Paste Daabacaadda Mac...

-

Jumlada Shiinaha ee dib-u-qulqulaya foornada, Iibka Dib-u-qulqulka SMT...

-

Mashiinka wax lagu gooyo ee Kapacitor weyn