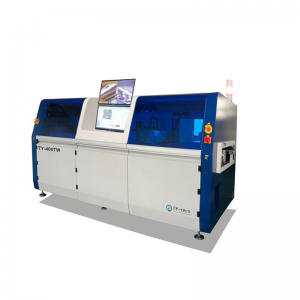

Leedh foornada dib ugu soo qulqulaya hawada kulul ee bilaashka ah TY-1220

Hordhac:

1. Computer brand iyo Siemens PLC nidaamka xakamaynta caqliga, xakamaynta heerkulka sare ee saxda ah waa ± 1-2 ℃ (haddii shilka kombiyuutarka, waxay ogaan kartaa shaqada ka baxsan, ma saameynayso wax soo saarka) iyo si loo hubiyo in nidaamka xakamaynta uu yahay deggan oo la isku halayn karo;

2. Windows XP interface interface oo leh hawlgal xoog badan oo fudud.

3.Si loo hubiyo badbaadada iyo isku halaynta, jidhka dhululubada ayaa si toos ah kor loogu qaadi karaa.

4. Qalabku wuxuu ku qalabaysan yahay suunka mesh, si habsami leh u qaada, ma ruxayo iyo wax qalloocan, kaas oo hubinaya in PCB-ga uu siman yahay.Habka gudbinta hagaha isku midka ah iyo isku xirka mashiinka SMT ee tooska ah ee khadka tooska ah ayaa hubiya hagaha la hagaajin karo saxnaanta ballaaran iyo nolosha adeeg sare.

5. Nidaamka sifaynta tooska ah ee xakamaynta iyo silsiladda gudbinta si toos ah.

6.Dhammaan xakamaynta aagga kulaylka ee kombuyuutar PID (aagga heerkulka sare iyo heerkulka hoose fulinta xakamaynta heerkulka madax-bannaan, taas macnaheedu waa inay kala qaybin karto kulaylka aagga, si loo yareeyo awoodda bilowga)

7. Isku-gudbinta shabakadda/silsiladda kombuyuutar si loo fuliyo dhammaan xakamaynta wareegga xiran, kaas oo la kulmi kara noocyada kala duwan ee wax soo saarka PCB isku mar.

8. Iyada oo leh dhawaaq khaldan iyo shaqeynta alaarmiga iftiinka.

9. Ilaaliyaha daadinta, hubi in shaqaalaha hawlgalka iyo nidaamka xakamaynta ay badbaadiyaan.

10.UPS-ku-dhisan iyo nidaamka daahitaanka otomaatiga ah ee daahitaanka dammaanad qaadista alxanka soo celinta tamarta ama kulaylka badan ma waxyeelo PCB iyo mishiinka.

11. Jarmalka ERSA adduunka oo hogaaminaya habka kuleyliyaha microcirculation, iyo nidaamka microcirculation hawada sare iyo hoose ee madax banaan, lebis heerkulka iyo kuleyl ah ee waxtarka sare leh, heer sare ah oo tayo sare leh supercharged hawo degdeg ah, si weyn u wanaajiso socodka hawada kulul wareegga, kululeeyo heerkulka si degdeg ah (ku saabsan. labaatan daqiiqo), magdhowga kulaylka ee waxtarka sare leh, alxanka heerkulka sare iyo daaweynta;

12. Sare iyo hoose ee aag kasta oo heerkul ah oo leh dareeraha heerkulka madaxa banaan, la socodka wakhtiga dhabta ah iyo magdhowga dheelitirka aaga heerkulka;

13. Hayso maamulka furaha sirta ah ee nidaamka qalliinka, si looga hortago in shaqaalaha aan khusayn isbedel ku saabsan xuduudaha habka, hawlgalka diiwaanada nidaamka raadraaca habraaca beddelo habka, hagaajinta maamulka habboon.Si aad u kaydiso isticmaaleha hadda jira ee xawaaraha heerkulka iyo Dejinta qalooca heerkulka, waxaana loo isticmaali karaa dhammaan xogta iyo daabacaadda qalooca;

14. Daaqadda kontoroolka isku-dhafan, kombuyuutarka beddelka, qalooca tijaabada, qalooca daabacaadda iyo gudbinta xogta ayaa si fudud u shaqaynaysa, naqshad bini'aadminimo.Ku qalabaysan nidaamka baadhista qalooca heerkulka saddex-channel, laga yaabaa in wakhti kasta lagu hubiyo alxanka walxaha by qalooca heerkulka dhabta ah (iyada oo aan la mid ah kale ee heerkulbeegga tijaabiyaha qalooca);

15. Laga soo bilaabo tignoolajiyada caalamiga ah ee nidaamka qaboojinta degdega ah, isticmaal nooca muraayadda weynaynta qaboojinta degdegga ah ee waxtarka leh, xawaaraha qaboojinta wuxuu gaari karaa 3.5 ~ 6 ℃ / SEC, maarayn waa mid aad u habboon;Qalabka qaboojinta qasabka ah ee dibadda, hubi in saamaynta kristal (Ikhtiyaarka la doortay walxaha, qaabeynta caadiga ah ee qaboojinta dabiiciga ah ee qasabka ah).

Faahfaahin:

| Qaabka | TY-Tech 1220 | ||

| Nidaamka Kululaynta | Tirada aagagga kuleylka | Kor 12/ hoose 12 | |

| Tirada aagagga qaboojinta | 2 | ||

| Dhererka aagagga kuleylka | 4640mm | ||

| Habka kululaynta | Hawo kulul | ||

| Qaabka qaboojinta | Qaboojinta hawada qasabka ah | ||

| Mugga Daminta | 10m³/daqiiqo * 2 daal | ||

| Nidaamka Gaadhida | Max.Baaxadda PCB | 400mm | |

| Ballaca suunka mesh | 450mm | ||

| Jihada Gudbinta | L→R (ikhtiyaarka: R→L) | ||

| Dhererka Net Gudbinta | 900± 20mm | ||

| Nooca gudbinta | Mesh iyo silsilad | ||

| Kala duwanaanshaha ballaca tareenka | 400mm | ||

| Xawaaraha wareejinta | 0-2000mm/min | ||

| Saliid toos ah/Manual | Heerka | ||

| Dhinaca tareenka go'an | Xadiidka hore ayaa go'an (ikhtiyaarka: tareenka gadaal ayaa go'an) | ||

| Qaybaha sare | Sare iyo hoose 25mm | ||

| Nidaamka xakamaynta | Korontada | 5 line 3 wajiga 380V 50/60HZ | |

| Wadarta awooda | 48KW | ||

| Isticmaalka tamarta caadiga ah | 10-12KW | ||

| Waqtiga diirimaad | 20 daqiiqo | ||

| Heerkulkabaaxadda dejinta | Laga soo bilaabo heerkulka qolka.Ilaa 300 ℃ | ||

| Heerkulkahabka xakamaynta | PID kontoroolka wareegga dhow & wadista SSR | ||

| Heerkulkaxakamaynta saxda ah | ±1℃ | ||

| Heerkulkaleexashada PCB | ±2℃ | ||

| Kaydinta xogta | Habka xogta iyo kaydinta heerka (80GB) | ||

| saxan sanka | Aluminium Aloy Plate | ||

| Alaarmiga aan caadiga ahayn | Heerkulka aan caadiga ahayn (heerkulka-sare-dheeraad ah) | ||

| Guddidu waxay tuurtay alaarmiga | Nalka Tower:Jaalle-kulul,Cagaar-caadi, Casaan-aan caadi ahayn | ||

| Guud ahaan | Cabirka (L*W*H) | 6300*1320*1490mm | |

| Miisaanka | 2600kg | ||

| Midabka | Computer cawlan | ||

Erayada FurahaFoornada Dib-u-soo-celinta ee SMT, Foornada Dib-u-soo-celinta Ledhka, Foornada Dib-u-soo-celinta Dhammaadka Sare, Dib-u-soo-celinta Foornada, Soo-saarka Foornooyinka Dib-u-soo-celinta, Foornada Dib-u-soo-celinta ee Dib-u-soo-celinta, Foornada Dib-u-soo-celinta ee PCB, Foornada Dib-u-soo-celinta Nitrojiinka, Foornada Dib-u-soo-celinta Dual Lane, Foornada Dib-u-soo-celinta Shiinaha, Mashiinka Alxanka PCB

FAQ:

Q. Waa maxay shuruudaha MOQ ee mashiinka?

A. 1 dhigay shuruudaha moq ee mashiinka.

S. Kani waa kii ugu horeeyay ee aan isticmaalo mishiinka noocaan ah, ma fududahay in la shaqeeyo?

J: Waxa jira buug-gacmeed Ingiriisi ah ama fiidiyoow hage oo ku tusaya sida loo isticmaalo mishiinka.

S: Haddii mishiinka uu leeyahay wax dhibaato ah ka dib markii aan helno, sideen samayn karnaa?

A: Injineerkeena ayaa kaa caawin doona inuu xalliyo marka hore, iyo qaybo bilaash ah ayaa kuu soo diri doona muddada dammaanadda mashiinka.

S: Ma bixisaa wax dammaanad ah mashiinka?

J: Haa 1 sano oo dammaanad ah ayaa la siin doonaa mashiinka.

S: Sideen kuugu dalban karaa?

J: Waxaad nagula soo xiriiri kartaa email ahaan, whatsapp, wechat oo aad ku xaqiijin kartaa qiimaha ugu dambeeya, habka dhoofinta iyo muddada lacag bixinta, ka dib waxaan kuu soo diri doonaa qaansheegta proforma oo leh faahfaahinta bangigayaga.