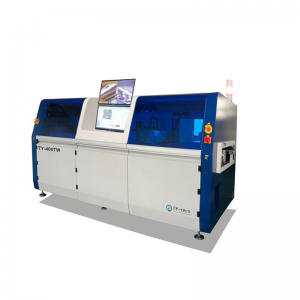

Muuqaal

1. Kombiyuutarka Brand LCD + PLC nidaamka xakamaynta caqli-galnimada ayaa la qaatay, oo leh saxnaanta heerkulka sare ee ± 1 ° C (haddii kombuyuutarku si lama filaan ah u dhaco, shaqada offline-ka ah ayaa la xaqiijin karaa iyada oo aan saameyn ku yeelan wax soo saarka), hubinta xasilloonida iyo kalsoonida nidaamka xakamaynta. ;

2. Windows7 interface interface, xoog badan oo sahlan in lagu shaqeeyo;

3. Furitaanka jirka foornada sare wuxuu qaataa labanlaab mashiinno koronto ah si loo hubiyo badbaadada iyo kalsoonida;

4. Ku qalabaysan qalabka suunka mesh, gaadiidku waa xasiloon yahay, ma ruxmayo, ma qalloocan, hubinta gaadiidka PCB oo siman;

5. Habka gudbinta tareenada hagaha isku midka ah (waxaa lagu xidhi karaa khadka tooska ah ee mashiinka meelaynta) si loo hubiyo hagaha saxda ah hagaajinta ballaca xadiidka iyo nolosha adeegga sare;(xadiidka hagaha ikhtiyaarka ah)

6. Si otomaatig ah u xakamee nidaamka saliidda, kaas oo si toos ah u saliidayn kara silsiladda gudbinta adoo dejinaya wakhtiga shidaal-qaadista iyo qadarka shidaalka;

7. Dhammaan aagagga kuleyliyaha waxaa gacanta ku haya PID kombuyuutar ( aagagga heerkulka si gooni ah ayaa loo furi karaa. Kuleyliyaha waxaa loo qaybin karaa aag si loo yareeyo awoodda bilowga);

8. Gudbinta shabakada/silsiladda waxaa si buuxda u xiran kombuyuutarku, kaas oo buuxin kara wax soo saarka isku mar ah ee noocyada kala duwan ee PCB-yada;

9. Iyada oo leh dhawaaq khaldan iyo shaqeynta digniinta iftiinka;

10. Lagu qalabeeyay ilaaliyaha daadinta si loo hubiyo badbaadada hawlwadeenada iyo nidaamka xakamaynta;

11. UPS-ku-dhisan iyo nidaamka daahitaanka tooska ah ee daahitaanka si loo hubiyo in PCB-ga iyo mishiinka alxanka ee dib-u-qulqulaya aanay dhaawacmin marka korantadu go'do ama la kululeeyo;

12. Qaado HELLER habka kululaynta wareegga hawada kulul, xawaaraha sare ee xawaaraha cadaadiska hawada, si weyn u kordhiso socodka hawada kulul, kor u kaca heerkulka degdega ah (qiyaastii 10 daqiiqo), waxtarka magdhowga kulaylka sare, iyo alxanka heerkulka sare leh iyo daaweynta;

13. Aagga heerkulku wuxuu ku qalabaysan yahay dareeraha dareeme heerkulka madax-bannaan si uu ula socdo loona magdhabo dheelitirka heerkulka aag kasta oo heerkul ah waqtiga dhabta ah;

14. Nidaamka qalliinka ee maareynta erayga sirta ah wuxuu ka hortagayaa shaqaalaha aan la xiriirin inay beddelaan cabbirrada habka, iyo maareynta diiwaanka hawlgalka waxay raadin kartaa habka isbeddelka ee cabbirrada habka, taas oo ku habboon hagaajinta maamulka.Waxay kaydin kartaa adeegsadaha xawaaraha heerkulka jira ee jira iyo qalooca heerkulka hoostiisa, waxayna bedeli kartaa dhammaan xogta daabacan iyo qaloocayada;

15. Daaqad isku dhafan oo kontorool ah, beddelka kombuyuutarka, qalooca tijaabada, qalooca daabacaadda iyo gudbinta xogta dhamaantood waa sahlan tahay in la shaqeeyo, naqshadeyntana waa mid bini'aadantinimo.Ku qalabaysan nidaamka baadhista qalooca heerkulka saddex-channel, kaas oo ogaan kara qalooca heerkulka dhabta ah ee shayga alxanka wakhti kasta (looma baahna in la habeeyo tijaabiyaha qalooca heerkulka);

16. Nidaamka qaboojinta degdega ah ee tiknoolajiyada caalamiga ah waxay qabataa weyneynta nooca muraayadda ah ee dhexdhexaadinta iyo qaboojinta degdegga ah, xawaaraha qaboojinta wuxuu gaari karaa 3.5 ~ 6 ° C / sec, maamulkuna waa mid aad u habboon;Qalabka qaboojinta qasabka ah ee dibadda ayaa hubisa saameynta crystallization ee kala-goysyada alxanka (Ikhtiyaarka ikhtiyaariga ah, qaabka caadiga ah ayaa lagu qasbay qaboojinta hawada dabiiciga ah);

17. Nidaamka soo kabashada Rosin: Rosin waxay u socotaa hab jihayn, taas oo aad ugu habboon beddelka iyo nadiifinta.Dhuumaha gaarka ah ayaa loo isticmaalaa in lagu gudbiyo gaaska qiiqa, taas oo aan dayactir lahayn nolosha;

18. Qaab dhismeedka gaadiidka hawada cadaadisay gaar ah iyo qaab gaar ah design silig kululaynta, buuq la'aan, gariir la'aan, heerka sarrifka kulaylka sare, farqiga heerkulka △t u dhexeeya hoose ee BGA iyo guddiga PCB waa mid aad u yar, taas oo si fiican u buuxisa adag. shuruudaha habka-lead-la'aanta , gaar ahaan alaabooyinka aan macdanta "lead" lahayn ee leh shuruudaha alxanka ee adag.

Sawirka Faahfaahin

Tilmaamaha

| Qaabka | TYtech 6010 | |

| Nidaamka Kululaynta | Tirada aagagga kuleylka | KOR 6/HOOS 6 |

| Tirada aagagga qaboojinta | Sare 1/BOOTTOM 1 | |

| Dhererka aagagga kuleylka | 2500MM | |

| Habka kululaynta | hawo kulul | |

| Qaabka qaboojinta | Hawada xoog | |

| Nidaamka Gaadhida | Max.Baaxadda PCB | 300mm |

| Ballaca suunka mesh | 400mm | |

| Jihada Gudbinta | L→R(ama R→L) | |

| Dhererka Net Gudbinta | 880± 20mm | |

| Nooca gudbinta | Mesh iyo silsilad | |

| Kala duwanaanshaha ballaca tareenka | 0-300mm | |

| Xawaaraha wareejinta | 0-1500mm/min | |

| Dhererka qaybta | Sare 35mm, hoose 25mm | |

| Saliid toos ah/Manual | heerka | |

| Habka daboolka sare | Dabool koronto oo otomaatig ah | |

| Dhinaca tareenka go'an | Xadiidka hore ayaa go'an (ikhtiyaarka: tareenka gadaal ayaa go'an) | |

| Qaybaha sare | Sare iyo hoose 25mm | |

| Nidaamka xakamaynta | Korontada | 5line 3 waji 380V 50/60Hz |

| Awood bilawga | 18kw | |

| Isticmaalka tamarta caadiga ah | 4-7KW | |

| Waqtiga diirimaad | Qiyaastii 20 daqiiqo | |

| Heerkulkabaaxadda dejinta | Heerkulka qolka-300 ℃ | |

| Heerkulkahabka xakamaynta | PLC & PC | |

| Heerkulkaxakamaynta saxda ah | ±1℃ | |

| Heerkulkaleexashada PCB | ±2℃ | |

| Kaydinta xogta | Habka xogta iyo kaydinta heerka (80GB) | |

| saxan sanka | Aluminium Aloy Plate | |

| Alaarmiga aan caadiga ahayn | Heerkul aan caadi ahayn.(ku-kulul-sare/dheeraad-hooseeya.) | |

| Guddidu waxay tuurtay alaarmiga | Iftiinka Tower: Jaalle-kulul, Cagaar-caadi, Casaan-aan caadi ahayn | |

| Guud ahaan | Cabirka (L*W*H) | 3600×1100×1490mm |

| Miisaanka | 900KG | |

| Midabka | Computer cawlan | |