Muuqaal

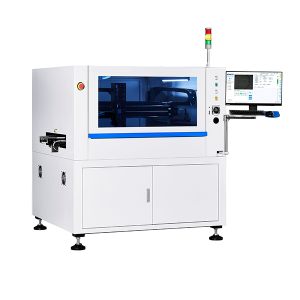

Soo-saare Shiinaha SMT Saxeexa Sare ee GKG Si Buuxda Oo Toomaatig Ah Looga Iibiyo

1. GKG G9+ shaqada ogaanshaha mashiinka daabacaadda koollada tooska ah ee alxanka:

Iyada oo la fulinayo magdhowga isha iftiinka ee ka sarreeya stencilka, CCD waxaa loo isticmaalaa in lagu hubiyo godadka mesh ee stencilka wakhtiga dhabta ah, si si dhakhso ah loo ogaado oo loo xukumo in stencilku xiran yahay nadiifinta ka dib, iyo in la sameeyo nadiifin toos ah, taas oo ah ogaanshaha 2D. habka loogu talagalay looxyada PCB.Buuxi

2. GKG G9+ mashiinka daabacaadda koollada tooska ah ee nidaamka qaybinta tooska ah:

Marka loo eego shuruudaha habraaca daabacaadda ee kala duwan, ka dib daabacaadda, bixinta saxda ah, bixinta daasadaha, sawirida khadka, buuxinta iyo hawlgallada kale ee shaqada ayaa lagu samayn karaa guddiga PCB;Isla mar ahaantaana, madaxa qaybinta ayaa sidoo kale lagu qalabeeyaa shaqada kuleylka, kaas oo loo isticmaali karo heerkulka hoose ee deegaanka Marka xabagta la kululeeyo, dareeraha xabagta ayaa la wanaajiyaa.

3. GKG G9+ mashiinka daabacaadda alxanka tooska ah nooca dhalada buuxinta tooska ah iyo shaqada ogaanshaha koollada:

Si toos ah ugu dar koollada alxanka waqtiyo go'an si loo hubiyo tayada koollada alxanka iyo cadadka koollada alxanka ee ku jira stencilka.Si loo hubiyo tayada daabacaadda macaamiisha iyo horumarinta wax soo saarka.Iyada oo loo marayo dareemayaasha, qadarka koollada alxanka ee stencil waa la maarayn karaa, tayada waa la dejin karaa.

Sawirka Faahfaahin

Tilmaamaha

| Waxqabadka mashiinka | |

| Ku celi saxnaanta booska | ± 10um@6 σ , CPK≥2.0 |

| Saxnaanta daabac | ±18um@6 σ , CPK≥2.0 |

| NCP-CT | 7s |

| HCP-CT | 18s/pcs |

| Habka CT | 4 daq |

| Beddel khadka CT | 2 daqiiqo |

| Halbeegga farsamaynta substrate | |

| Cabbirka guddiga ugu sarreeya | 450*340mm |

| Cabirka guddiga min | 50*50mm |

| Dhumucda looxa | 0.4 ~ 6mm |

| Kala duwanaanshaha farsamada kamarada | 450*340mm |

| Miisaanka looxa ugu badan | 3kg |

| Nadiifinta guddiga | 2.5mm |

| Dhererka looxa | 15mm |

| Xawaaraha gaadiidka | 900± 40mm |

| (Max) Xawaaraha gaadiidka | 1500mm/s ugu badnaan |

| Jihada gaadiidka | Hal marxalad |

| Jihada gudbinta | Bidix ilaa midig |

| Midig ilaa bidix | |

| Gudaha iyo dibaddaba isku mid | |

| Nidaamka taageerada | Magnetic pn |

| Taageerada xannibaadda | |

| Miiska gacanta-sare | |

| Guddi qoyan | Isku dhejinta tooska ah |

| Xajinta dhinaca | |

| Shaqada adsorption | |

| Xuduudaha daabacaadda | |

| Xawaaraha daabac | 10-200mm/s |

| Cadaadiska daabacaadda | 0.5-10kg |

| Habka daabacaadda | Hal/laba jeer |

| Nooca Queegee | Caag, daab xoqan (xagal 45/55/60) |

| Deg deg | 0-20mm |

| Xawaaraha sanp | 0-20mm/s |

| Cabbirka qaab-dhismeedka qaab-dhismeedka | 470*370mm-737*737mm ( dhumucdiisuna waa 20-40mm) |

| Qaabka meelaynta mesh birta | Meelaynta jihada tooska ah ee Y |

| Hababka nadiifinta | |

| Nidaamka nadiifinta | Qalalan, qoyan, faaruq ah, saddex nooc |

| Nadiifinta xawaaraha sare | Nadiifinta isku dhafan & tidde |

| Nidaamka nadiifinta | Nooca buufinta dhinaca |

| Nadiifinta istaroogga | Jiilka tooska ah |

| Meesha nadiifinta | Nadiifinta ka hor |

| Xawaaraha nadiifinta | 10-200mm/s |

| Nadiifinta isticmaalka dareeraha | Gacanta lagu hagaajin karo |

| Nadiifinta isticmaalka aabbaha | Gacanta lagu hagaajin karo |

| Halbeegyada aragga | |

| CCD FOV | 10*8mm |

| Nooca kamarada | 130 kun CCD kamarad dijital ah |

| Nidaamka kamarada | Kor/hoos u xidh qaab-dhismeedka indhaha |

| Waqtiga wareegga kamarada | 100ms |

| Noocyada calaamadaynta | Qaabka caamka caamka ah |

| Wareeg, afar gees ah, dheeman, iskutallaab | |

| Pad iyo profile | |

| Calaamadee cabbirka | 0.1-6mm |

| Calaamadee lambarka | Max.4pcs |

| Ka fogow nambar | Max.1pc |

| Halbeegga mashiinka | |

| Isha tamarta | AC 220 ± 10%, 50/60Hz 2.2KW |

| Cadaadiska hawada | 4 ~ 6kgf/cm² |

| Isticmaalka hawada | ~5L/daqiiqo |

| Heerkulka shaqada | -20°C~+45°C |

| Qoyaanka deegaanka oo shaqaynaya | 30%-60% |

| Cabirka mashiinka (la'aanteed iftiin ubax) | 1172 (L)*1385(W)*1530(H)mm |

| Miisaanka mashiinka | Qiyaastii 1000kg |

| Shuruudaha xajinta qalabka | 650kg/m² |