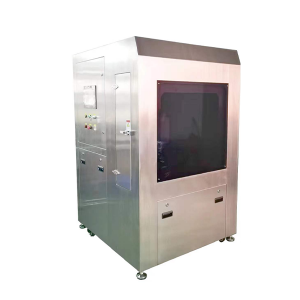

Sebopeho

● Sesebelisoa sa ho fafatsa se nang le khatello e phahameng se sebelisoa ka ho khetheha bakeng sa mokelikeli oa ho hloekisa ka metsi ho hloekisa skrine, poleiti e fosahetseng, mochine oa khatiso oa mochine le mekhoa e meng.

● Tanka e nang le metsi a mabeli, e nang le sesebelisoa sa ho futhumatsa, ho finyella litlhoko tsa ho hloekisa, ho hlatsoa le ho omisa moea o chesang.

● Phallo ea ts'ebetso: ho hloekisa - ho itšehla thajana ka lik'hemik'hale - ho hlatsoa ka mokhoa o thata (ho buloa / ho koalehile loop) - ho hlatsoa hamonate (ho butsoe / ho koetsoe loop) - ho omisa.

● Tokisetso ea software e tsoetseng pele ka ho feletseng ea ts'ebetso ea skrine ea ho ama, lifaele tsa lenaneo lia bolokoa, 'me tšebeliso e bonolo haholo.

● Ts'ebetso ea ho bala tsamaiso, e ka bokellang palo ea li-stencil tsa ho hloekisa le palo ea linako tse potolohang tsa ho hloekisa.

● Khatello ea metsi le pompo e ka bontšoa ka mochine oa khatello ea phanele, 'me boemo ba ts'ebetso ea thepa bo ka feptjoa ka nako.

● Khatello ea spray e hlahlojoa ke mochine oa khatello, 'me ho tla fanoa ka alamo haeba khatello e feta tekanyo ea khatello e behiloeng.

●Mokelikeli o khutla ka kotloloho ho fokotsa tšebeliso ea metsi

● 'Mele oa tšepe o sa hloekang ka kakaretso o tiile ebile o tšoarella nako e telele, o hanana le asiti, alkali le maro a mang a hloekisang.the

● Mohatla o phahameng oa khatello + o omisa moea o chesang, phello ea ho omisa e potlakile le ho feta.

● Litšenyehelo tse tlase tsa ts'ebetso, ke 50-200ml feela ea metsi e hlokahalang bakeng sa tlhoekiso e 'ngoe le e' ngoe, 'me moea o hatelitsoeng o sebelisetsoa ho khutlisa mokelikeli o setseng pompong le pompo ka mor'a ho hloekisa, e ka fokotsang tšebeliso ea metsi ka 50%.

Mosebetsi:

1. Mokhoa oa ho hloekisa lisebelisoa: ka letsohong le letšehali le ka ho le letona mohala o nang le mahlakore a mabeli a lekanang a khatello ea metsi a mabeli, mochine o nka mochine oa optical axis, high-precision ball screw, e khannoang ke ho hatakela motlakase ho etsa hore matla a le letšehali le a nepahetseng a khutlisetse, ho etsa bonnete ba hore o nepahetse. reset nako le nako le nako e telele bophelo , ho le bonolo ho boloka kapa ho nkela sebaka, tsamaisa bareng spray reciprocating le letšehali le le letona ho fafatsa, o ka khetha sebaka sa sebakeng seo ho finyella targeted spraying, le tsitsipano ea tšepe letlooeng ke ke a ameha ka mor'a ho hloekisa.

2. Litšila tsa solder paste li arotsoe ka mokhoa o hlophisehileng, 'me tšebeliso ea fiber adsorption le liphello tsa filtration e etsa hore tlhokomelo e be bonolo haholoanyane.

3. Ponahalo, ts'ebetso eohle ea ho hloekisa, ts'ebetso ea skrine ea ho ama e bonolo haholoanyane, ts'ebetso ea memori ea lenaneo.

4. Mochine o entsoe ka mokhoa oa ho hloekisa, mokhoa oa ho itšeha, mokhoa oa ho hlatsoa, mochine oa ho omisa le mokhoa oa ho hloekisa.Mochine o sebelisa motlakase le khase e le mehloli ea matla, ka letsoho o kenya stencil ka kamoreng ea ho hloekisa, ka mor'a ho beha ho hloekisa, ho hlatsoa, ho omisa le likarolo tse ling tse amanang le skrine ea ho ama, tobetsa konopo ea ho qala, stencil e tla hloekisoa, e hlatsuoe le ho hlatsuoa. omisitsoeng .Ha ts'ebetso ea ho hloekisa e felile, e tla emisa ho sebetsa le ho qala bocha ho hlokomela ts'ebetso e latelang ea ts'ebetso.Mosebetsi oa software oa mochine o matla haholo, o ka bolokang tlhahisoleseding e tobileng ea ho hloekisa skrine (nako, makhetlo a mangata, nako ea ho itšeha, maqhubu, nako ea ho hlatsoa, maqhubu, nako ea mocheso oa ho omisa, maqhubu, joalo-joalo) ea skrine ea ho hloekisa.Mochine o loketse haholo bakeng sa opereishene ho hloekisa Stencil, molekane oa pele ho ntlafatsa katleho ea tlhahiso le boleng.Ke mofuta o mocha oa lisebelisoa tsa ho itlhoekisa ka boiketsetso tse sebetsang hantle haholo.Thepa e sebelisa metsi a thehiloeng metsing kapa DI metsi e le sesebelisoa sa ho hloekisa, ntle le kotsi leha e le efe ea polokeho 'me ha ho kotsi ho basebetsi.

5. Ho omisa moea o chesang: Fane e nang le khatello e phahameng e kena ka thipa ea moea ka lebokose la ho futhumatsa ho omisa likarolo tse hloekisitsoeng kapele.

Setšoantšo se qaqileng

Litlhaloso

| Mohlala | TY-S750 |

| Tekanyo ea Mochini | 1220mm(L)*1120mm(W)*1850mm(H) |

| Boima ba Mochini | 580KG |

| StencilSize | Max750*750*40mm |

| CtshetlehileQbonngoe | 1pc |

| SrapelaPthoba maikutlo | 2-3KG (boleng bo felletseng ba khatello) |

| Bophahamo bo phahameng ba tanka ea metsi | 50L*2PCS |

| Tšebeliso e Ntle ea Mokelikeli | 40L*2PCS |

| Bonyane bo phahameng ba tharollo ea ts'ebetso | 20L*2PCS |

| Npalo ea lipompo | 3likhomphutha(Pompo e le 'ngoe ea solvent, pompo e le 'ngoe ea ho hlatsoa, pompo e le 'ngoe ea metsi) |

| Tsamaiso / Tsamaiso ea Ts'ebetso | Mitsubishi PLC + China Taiwan Weilun touch screen |

| CtshetlehileStsamaiso | Pompo e ikemetseng ea khatello e phahameng ea motlakase ho ntša mokelikeli + ka ho le letšehali le ka ho le letona e ka suthehang ka mahlakoreng a mabeli a isobaric nozzle nozzle e hloekisang ka khatello e phahameng ea khatello. (Pompo e ikemetseng e ka qoba ho tsamaisa metsi ka nepo le ho fokotsa maqhubu a ts'ebetso ea pompo ho eketsa makhetlo a ts'ebeliso) |

| Sistimi ea ho khutlisa | Beha nako ea reflux ho metsotsoana e 40-60 (ka ho feletseng lumella moemeli oa ho hloekisa ho khutlela tanka ea solvent ho boloka potion) |

| Rtsamaiso ea methapo | Pompo e ikemetseng ea motlakase e phahameng ea khatello ea ho ntša metsi a hlatsuoang + ka ho le letšehali le ka ho le letona e ka suthehang ka mahlakoreng a mabeli a isobaric nozzle nozzle e hloekisang ka khatello e phahameng ea khatello. (Pompo e ikemetseng e ka qoba ho tsamaisa metsi ka nepo le ho fokotsa maqhubu a ts'ebetso ea pompo ho eketsa makhetlo a ts'ebeliso) |

| Dtsamaiso ea ho lla | Ho futhumala ha lebokose le futhumatsang + moea o chesang oa moea o ka morao + ho kuta ka ho le letšehali le ka ho le letona ho tsamaisang moea |

| Ftsamaiso ea ho hloekisa | Tlhophiso e phahameng Sefe ea Boemo ba 1: Sefa litšila le lileibole Filtration ea mekhahlelo e 2: sefate sa solder le likaroloana tsa rosin Filtration ea mekhahlelo e 3: likaroloana tsa 1μm tse kang solder paste, rosin, sekhomaretsi se sefubelu le litšila. |

| Ho hloekisaPrinciple | Ho hloekisa ka khatello e phahameng + ho hlatsoa |

| CtshetlehileMethod | Pompe ea motlakase ea diaphragm e ntša ntho e hloekisang ka mor'a ho sefa, ebe e fafatsa hlooho ea sefaha ka har'a kholomo ea metsi e bōpehileng joaloka fene holim'a sethala sa isobaric se ka letsohong le letšehali ho hloekisa letlooeng la tšepe le scraper, le ho tlosa sekhomaretsi se sefubelu, sekhomaretsi se sefubelu. , enke, resin le litšila tse ling Hlakola, ebe u hlatsoa ka mokhoa o ts'oanang |

| Lisebelisoa tsa Lisebelisoa | E na le li-caster tse tsitsitseng tse khethehileng |

| Thepa ea thepa | 304 thepa ea tšepe e sa hloekang (botenya ba 1.5mm) |

| Lisebelisoa tsa phala ea lisebelisoa | Lintho tse bonahalang tsa PPH (Bophelo bo bolelele, ho hanyetsa mocheso o phahameng, acid e matla le khanyetso ea alkali, ha ho na sekhahla, ho bonolo ho e nkela sebaka, joalo-joalo) |

| Mokelikeli o sebetsang oa ho hloekisa | mohloekisi oa metsi |

| Tahlehelo ea potoloho e le 'ngoe / leqephe | <200ml Ho itšetlehile ka boholo, bongata, nako ea ho hloekisa, le mocheso oa mocheso oa sehlahisoa sa ho hloekisa |

| Imatla a nput | AC380V 50HZ 50A |

| Tmatla a otal | 25KW |

| Ikhatello ea moea | 0.4-0.6MPa |

| Abophahamo ba modumo | 200 L/min @ Ho hloekisa (ho sebelisoa nakong ea ho hloekisa) 600L/min @ Drying (ho omisa tshebediso ya ho fokotsa moya) |

| Litlhoko tsa Exhaust Velocity | 7.5m³/min, kenya feela phala ea ho qeta Φ125 |

| Pipeline | Lipompompe tse tharo le lipeipi tse tharo (Pompo e ikemetseng e ka qoba ho tsamaisa metsi ka nepo le ho fokotsa maqhubu a ts'ebetso ea pompo ho eketsa makhetlo a ts'ebeliso) |

| Dmokhoa oa ho lla | thipa ea moea e sehang metsi + ho omisa moea o chesang (Ntlafatsa phello ea ho omisa le ho fokotsa nako ea ho omisa) |

| Ho omisa molao-motheo | Ho futhumala ha tube e futhumatsang, moea o chesang o khutlela morao, ka ho le letšehali le ka ho le letona ho tsamaea ka mahlakoreng a mabeli. |

| Dmocheso o llang | mocheso oa kamore -60 ° (Ka mor'a liteko tse pheta-phetoang, ho feta 60 ° ho tla senya sekhomaretsi sa foreimi ea skrine, 'me moeli o ka holimo oa lenaneo ke 60 ° ho qoba tšenyo ea foreimi ea skrine e bakoang ke ts'ebetso e sa lokelang) |

| Palo ea li-nozzles | 22likhomphutha |

| Palo ea litanka tsa ho hloekisa | 1pc |

| Palo ea litanka tsa ho hlatsoa | 1pc |

| Ho koala mokhoa oa ho hloekisa tanka | Lera la pele: tiiso ea monyako oa tšepe Lera la bobeli: E tiisitsoe ka lesale la ho thibela ho bola, 'me valve ea tšireletso e tsoang linaheng tse ling e koetsoe ho sireletsa ka katleho tšireletso ea mokhanni le sehlahisoa. |

| Cbokgoni ba ho itshetleha | Sekhomaretsi sa solder, sekhomaretsi se khubelu le enke li ka hloekisoa ka ho feletseng |

| Hlatsoa + Nako e omileng | Ho hloekisa ka ho qhibiliha: metsotso e 2-5 (bakeng sa litšupiso feela) Rinse: metsotso e 1-3 (bakeng sa litšupiso feela) Ho omisa: Metsotso e 2-5 (bakeng sa litšupiso feela) 1-999S nako ea ho hloekisa le ho omisa e ka behoa ka thoko |

| Mokhoa oa ho hloekisa mokelikeli | E na le phaephe e khethehileng bakeng sa ho ntšoa ka boiketsetso |

| Mokhoa oa ho hloekisa tharollo ea tharollo | E na le phaephe e khethehileng bakeng sa ho ntšoa ka boiketsetso |

| Viewport | E, (kamore ea ho hloekisa e na le mabone a LED bakeng sa ho lemoha habonolo phello ea ho hloekisa) |

| Ophanele ea peration | Thepa skrine, likonopo, setopong sa tšohanyetso, konopo ea ho qala, konopo ea ho seta bocha |

| E sebelisoa ho hloekisa stencil ea COB | EE |

| Lintho tse ka sebelisoang | Moemeli oa ho hloekisa ka metsi, ntho ea filthara |

| Lintho tsa tlhokomelo, khafetsa le nako e jang | 1. Filter element: 1 khoeli (ho nka metsotso e 5 ho fetola) 2. Ho nkela solvent sebaka: Likhoeli tse 3 (ho nkela sebaka se nka metsotso e 30) 3. Ho hloekisa hlooho ka sefafatsi: Likhoeli tse 6 (ho hloekisa ho nka metsotso e 10) Lintlha tse ka holimo ke tsa litšupiso feela, 'me li ka nkeloa sebaka ka mokhoa o ikhethileng ho latela khafetsa ea ho hloekisa sehlahisoa. |

-

PCBA Cleaning Machine Bakeng sa SMT Machine Line PCB ...

-

Mochini oa ho Hloekisa Nozzle oa SMT Full Automatic Nozzle TYte...

-

Mochini oa ho Hloekisa Stencil oa Pneumatic TY-750

-

Full Automatic Off-line PCBA Cleaning Machine T...

-

TY-7000 Online PCBA Mochine oa ho Hloekisa ka Metsi

-

Mochini oa ho Hloekisa oa Solder Pallets TY-C800