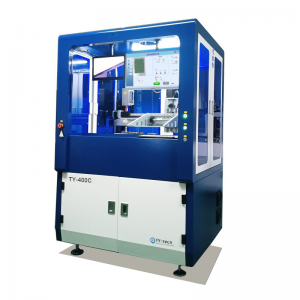

Etella pele Ho Fetisisa Moea o Chesang Oven TYtech 8020

Selelekela:

1. Khomphuta ea brand le Siemens PLC tsamaiso e bohlale ea ho laola, taolo e phahameng ea mocheso o nepahetseng ke ± 1-2 ℃ (haeba kotsi ea kotsi ea k'homphieutha, e ka lemoha mosebetsi oa off-line, e se ke ea ama tlhahiso) le ho etsa bonnete ba hore tsamaiso ea taolo e teng. e tsitsitseng le e ka tšeptjoang;

2. Sehokelo sa tšebetso sa Windows XP se nang le ts'ebetso e matla le e bonolo.

3.E le ho netefatsa tšireletseho le ho tšepahala, 'mele oa silinda o ka phahamisoa ka bohona.

4. Sesebelisoa se na le lebanta la letlooeng, se tsamaisang hantle, ha se sisinyehe ebile ha se na deformation, se netefatsang lipalangoang tsa PCB tse boreleli.Mochine oa phetisetso ea tataiso ea synchronous le khokahano ea inthanete ea mochini oa SMT e netefatsa hore e tataisa ho nepahala ho feto-fetohang le bophelo ba ts'ebeletso e phahameng.

5. Automatic control lubrication system le automatic lubrication transmission chain.

6.Taolo eohle ea ho futhumatsa sebaka ka komporo ea PID (sebaka se kaholimo sa mocheso le sebaka se tlase sa mocheso oa sebaka sa mocheso se ikemetseng, ho bolelang hore se ka arola mocheso oa sebaka sa mocheso, e le ho fokotsa matla a ho qala)

7. Phetiso ea marang-rang / ketane ka komporo ho phethahatsa taolo eohle e koetsoeng ea loop, e ka kopanang le mefuta e fapaneng ea tlhahiso ea PCB ka nako e le 'ngoe.

8. Ka molumo oa phoso le ts'ebetso ea alamo e bobebe.

9. Ka mosireletsi oa leakage, etsa bonnete ba hore ts'ireletso ea ts'ebetso ea basebetsi le tsamaiso ea taolo.

10.The a haha-ka UPS le jarolla ka ho iketsa tieho shutdown tsamaiso tiisetso khutlela welder ka matla kapa overheat u se ke ua senya PCB le mochine.

11. The Jeremane ERSA lefatše etella pele microcirculation futhumatsang mokgwa wa, le ka holimo le ka tlaase ikemetseng moea microcirculation tsamaiso, mocheso tšoanang le mogote puseletso phahameng bokgoni, phahameng sebetsang hantle supercharged accelerated moea duct, haholo ntlafatsa ho potoloha ho potoloha moea o chesang, futhumatsa mocheso ka potlako metsotso e mashome a mabeli), matšeliso a mocheso bakeng sa katleho e phahameng, mocheso o phahameng oa ho cheseletsa le ho phekola;

12. Sebaka se seng le se seng sa mocheso le se tlase se nang le sensor e ikemetseng ea mocheso, tlhahlobo ea nako ea sebele le matšeliso a sebaka se seng le se seng sa mocheso;

Tlhaloso:

| Mohlala | TYtech 8020 | |

| Sistimi ea ho futhumatsa | Palo ea libaka tse futhumatsang | Holimo ho 8/ tlase ho 8 |

| Palo ea libaka tsa ho pholisa | 2 | |

| Bolelele ba libaka tsa ho futhumatsa | 3100 limilimithara | |

| Mokhoa oa ho futhumatsa | Moea o chesang | |

| Mokhoa oa ho Pholisa | Pholiso ea moea e qobelloang | |

| Molumo oa Exhaust | 10m³/min * 2 exhauss | |

| Sistimi ea Conveyor | Max.Bophara ba PCB | 400mm |

| Bophara ba lebanta la Mesh | 500 limilimithara | |

| Tataiso ea phetiso | L→R(khetho: R→L) | |

| Phetiso Net Height | 900±20mm | |

| Mofuta oa phetiso | Mesh le ketane | |

| Bophara ba seporo | 50-400 limilimithara | |

| Lebelo la conveyor | 0-2000mm/min | |

| Auto/manual Lubrication | Standard | |

| Lehlakore la terene le tsitsitseng | Seporo se ka pele se tsitsitse (khetho: seporo sa ka morao se tsitsitse) | |

| Likarolo tse phahameng | Ka holimo le tlase 25mm | |

| Tsamaiso ea taolo | Phepelo ea motlakase | 5 line 3 phase 380V 50/60HZ |

| Matla a qalang | 38KW | |

| Tšebeliso e tloaelehileng ea matla | 6-9KW | |

| Nako ea ho futhumala | 20 mets | |

| Temp.setting range | Ho tloha mocheso oa kamore.Ho fihlela ho 300 ℃ | |

| Temp.mokhoa oa ho laola | PID haufi le taolo ea loop & ho khanna SSR | |

| Temp.ho laola ka nepo | ±1℃ | |

| Temp.ho kheloha ho PCB | ±2℃ | |

| Polokelo ea data | Ts'ebetso ea data le boemo ba polokelo (80GB) | |

| Letlapa la nozzle | Aluminium Alloy Plate | |

| Alamo e sa tloaelehang | Mocheso o sa tloaelehang (mocheso o phahameng haholo / o tlase haholo) | |

| Boto e ile ea liha alamo | Tower light:Ho futhumala ha mosehla, Botala-tloaelehileng, Bofubelu-bo sa tloaelehang | |

| Kakaretso | Dimension(L*W*H) | 5300*1320*1490mm |

| Boima ba 'mele | 2000kg | |

| Mmala | K'homphieutha e bohlooho | |

Delivery: ka leoatle.

Nako ea ho tsamaisa: 10-25 matsatsi a ho sebetsa.

Sephutheloana: Lebokose la lehong.

Mantsoe a sehlooho: Mochine oa SMT,mochini o kopanyang oa pcb,mochini o etsang led,led reflow ontong,pcb reflow ontong,smt reflow ontong,reflow soldering ontong,mochini o futhumatsang oa onto,tlhahiso ea ontong ea reflow, Lead free smt reflow oven, hot air reflow ontong, China reflow ontong moetsi, solder ontong bakeng sa smd.

TYtech automation e ka fana ka lisebelisoa tse felletseng tsa smt ho kenyelletsa mochini oa solder,ho khetha le ho beha mochini,mochine oa khatiso oa solder,mochini o tsamaisang smt,AOI/SPI,lisebelisoa tsa smt peripheral,likarolo tsa smt etc, any requirement please contact us by call, wechat, whatsapp: 008615361670575, email: frank@tytech-smt.com.

LBH:

Q. Tlhokahalo ea hau ea MOQ bakeng sa mochini ke efe?

A. 1 beha tlhokahalo ea moq bakeng sa mochine.

P. Lena ke lekhetlo la pele ke sebelisa mochini oa mofuta ona, na o bonolo ho o sebetsa?

A: Ho na le bukana ea Senyesemane kapa video e tataisang e u bontšang mokhoa oa ho sebelisa mochine.

P: Haeba mochine o na le bothata leha e le bofe ka mor'a hore re o fumane, re ka etsa joang?

A: Moenjiniere oa rona o tla thusa ho e rarolla pele, 'me likarolo tsa mahala li u romella ka nako ea tiiso ea mochine.

P: Na u fana ka tiisetso efe kapa efe bakeng sa mochine?

A: E, tiisetso ea selemo sa 1 e tla fanoa bakeng sa mochine.

P: Nka odara joang ho uena?

A: O ka re fihlela ka lengolo-tsoibila, whatsapp, wechat le ho netefatsa theko ea hae ea ho qetela, mokhoa oa ho romella le nako ea ho lefa, ebe re tla u romella invoice ea proforma e nang le lintlha tsa rona tsa banka ho uena.

-

Automatic pcb itšeha mochini phahameng ho nepahala Vc...

-

PCBA Cleaning Machine Bakeng sa SMT Machine Line PCB ...

-

Top quality Siplace TX Pick And Place Machine

-

Mochini oa PCB Flip Reversak

-

Sistimi e le 'ngoe ea 4 ea Flying Probes Test System TY-4T

-

TYtech High Quality Offline Selective Wave E Rekisitsoe...