Reflow soldering ke mokhoa o sebelisoang ka ho fetesisa oa ho hokela likarolo tsa holim'a marulelo ho liboto tsa potoloho tse hatisitsoeng (PCBs).Sepheo sa ts'ebetso ke ho theha manonyeletso a amohelehang ka ho qala pele ho futhumatsa likarolo / PCB / solder peista ebe o qhibilihisa solder ntle le ho baka tšenyo ka ho chesa.

Lintlha tse ka sehloohong tse lebisang ts'ebetsong e sebetsang ea reflow soldering ke tse latelang:

- Mochini o loketseng

- Boemo bo amohelehang ba ho khutlisa

- PCB/component footprint Design

- PCB e hatisitsoeng ka hloko ho sebelisoa stencil e entsoeng hantle

- Ho beoa ho phetoang ha likarolo tsa holim'a thaba

- PCB ea boleng bo botle, likarolo le peista ea solder

Mochini o loketseng

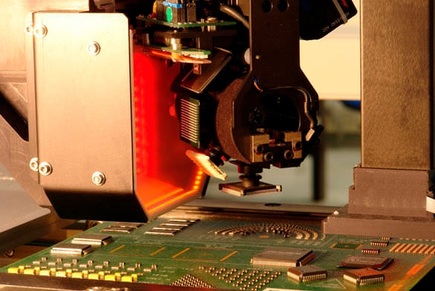

Ho na le mefuta e fapaneng ea mochini oa ho hlabolla o fumanehang ho latela lebelo la mohala o hlokahalang le moralo / thepa ea likopano tsa PCB tse lokelang ho sebetsoa.Setofo se khethiloeng se hloka ho ba sa boholo bo loketseng ho sebetsana le sekhahla sa tlhahiso ea thepa ea ho khetha le ho beha.

Lebelo la mohala le ka baloa joalo ka ha ho bonts'itsoe ka tlase: -

Lebelo la mola (bonyane) =Liboto ka motsotso x Bolelele ka boto

Load Factor (sebaka pakeng tsa liboto)

Ho bohlokoa ho nahana ka ho pheta-pheta ha ts'ebetso mme kahoo 'Moroalo oa Moroalo' hangata o hlalosoa ke moetsi oa mochini, lipalo tse bontšitsoeng ka tlase:

Ho khona ho khetha boholo bo nepahetseng reflow ontong lebelo la ts'ebetso (le hlalositsoeng ka tlase) le tlameha ho ba kholo ho feta lebelo le lekantsoeng la mohala.

Lebelo la ts'ebetso =Kamore ea ontong halefile bolelele

Nako ea nako ea ts'ebetso

Ka tlase ke mohlala oa lipalo ho theha boholo bo nepahetseng ba onto: -

Sekopanyi sa SMT se batla ho hlahisa mapolanka a 8-inch ka sekhahla sa 180 ka hora.Moetsi oa peista ea solder o khothaletsa metsotso e 4, profil ea mehato e meraro.Ke hloka onto ea nako e kae ho sebetsa liboto mosebetsing ona?

Liboto ka motsotso = 3 (180/hora)

Bolelele ka boto = 8 inches

Load Factor = 0.8 (sebaka sa 2-inch lipakeng tsa liboto)

Mokhoa oa ho lula nako = metsotso e 4

Bala Lebelo la Mohala:(3 liboto/mots) x (8 lisenthimithara/boto)

0.8

Lebelo la mola = 30 inches/ motsotso

Ka hona, ontong ea reflow e tlameha ho ba le lebelo la ts'ebetso bonyane lisenthimithara tse 30 ka motsotso.

Etsa qeto ea bolelele ba kamore ea ontong ka lebelo la lebelo la equation:

30 ho/mots =Kamore ea ontong halefile bolelele

Metsotso e 4

Bolelele bo futhumetseng ba onto = lisenthimithara tse 120 (maoto a 10)

Hlokomela hore bolelele bohle ba ontong bo tla feta maoto a 10 ho kenyelletsa le karolo ea pholileng le likarolo tsa ho kenya conveyor.Palo ke ea HATETED LENGTH – HASE KAOFELA OVEN LENGTH.

1. Mofuta oa conveyor - Hoa khoneha ho khetha mochine o nang le mesh conveyor empa ka kakaretso li-conveyor tse bohale li hlalositsoe ho nolofalletsa onto hore e sebetse ka mohala le ho khona ho sebetsana le likopano tse mahlakoreng a mabeli.Ho phaella ho conveyor ea bohale setsi-ts'ehetso-boto hangata e kenyelelitsoe ho thibela PCB hore e se ke ea sisinyeha nakong ea ts'ebetso ea reflow - bona ka tlase.Ha o sebetsana le likopano tse nang le mahlakoreng a mabeli a sebelisa mochine oa conveyor tsamaiso ea bohale e tlameha ho nkoa e le hore e se ke ea senya likarolo tse ka tlaase.

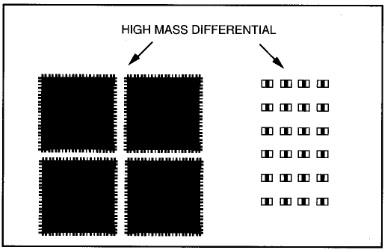

2. Taolo ea loop e koetsoeng bakeng sa lebelo la li-fans tsa convection - Ho na le liphutheloana tse ling tse holim'a holim'a metsi tse kang SOD323 (sheba ho kenya) tse nang le sebaka se senyenyane sa ho kopana le tekanyo ea boima e ka 'nang ea khathatsoa nakong ea ts'ebetso ea ho tsosolosa.Taolo ea lebelo e koetsoeng ea li-fans tsa likopano ke khetho e khothalletsoang bakeng sa likopano tse sebelisang likarolo tse joalo.

3. Taolo e ikemetseng ea li-conveyor le li-center-board-support widths - Mechini e meng e na le phetoho ea bophara ba matsoho empa haeba ho na le likopano tse ngata tse fapaneng tse lokelang ho sebetsoa ka bophara bo fapaneng ba PCB joale khetho ena e khothalletsoa ho boloka ts'ebetso e tsitsitseng.

Profaele e Amohelehang ea Reflow

- Mofuta oa solder paste

- Lisebelisoa tsa PCB

- Botenya ba PCB

- Palo ea lihlopha

- Bongata ba koporo ka har'a PCB

- Palo ea likarolo tsa holim'a thaba

- Mofuta oa likarolo tsa holim'a thaba

Bakeng sa ho theha "reflow profile thermocouples" li hokahane le kopano ea sampole (hangata e nang le solder e phahameng ea mocheso) libakeng tse 'maloa ho lekanya mefuta e fapaneng ea mocheso ho pholletsa le PCB.Ho khothaletsoa ho ba le bonyane thermocouple e le 'ngoe e lutseng holim'a pad ho ea pheletsong ea PCB le thermocouple e le 'ngoe e lutseng holim'a pad ho ea bohareng ba PCB.Hantle-ntle li-thermocouples tse ngata li lokela ho sebelisoa ho lekanya mefuta eohle ea mocheso ho pholletsa le PCB - e tsejoang e le 'Delta T'.

Ka har'a profil e tloaelehileng ea reflow soldering hangata ho na le mekhahlelo e mene - Preheat, soak, reflow le cooling.Sepheo se seholo ke ho fetisetsa mocheso o lekaneng ka har'a kopano ho qhibilihisa solder le ho theha manonyeletso a solder ntle le ho baka tšenyo ea likarolo kapa PCB.

PreheatNakong ena likarolo, PCB le solder kaofela li futhumatsoa sebakeng se itseng sa soak kapa mocheso o lulang o le hlokolosi hore o se ke oa futhumatsa ka potlako (hangata ha o fete 2ºC / motsotsoana - hlahloba database ea solder paste).Ho futhumala kapele haholo ho ka baka liphoso tse joalo ka likaroloana hore li phatlohe le peista ea solder ho splatter e bakang libolo tsa solder nakong ea reflow.

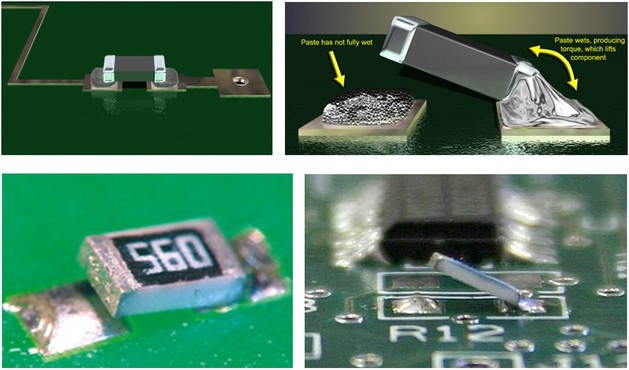

Soak- Sepheo sa mohato ona ke ho etsa bonnete ba hore likarolo tsohle li fihla mocheso o hlokahalang pele o kena sethaleng sa reflow.Soak hangata e nka metsotsoana e 60 ho isa ho e 120 ho latela "phapang ea bongata" ea kopano le mefuta ea likarolo tse teng.Ha ho fetisoa ha mocheso ho sebetsa hantle haholo nakong ea soak ho hloka nako e fokolang.

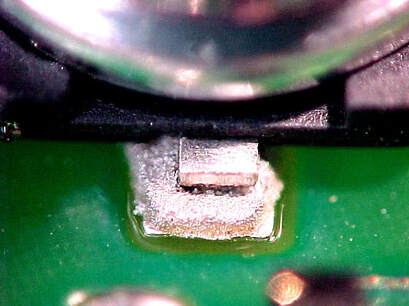

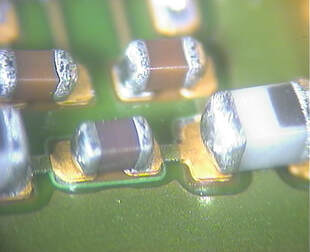

Phoso e tloaelehileng ea solder ka mor'a ho phalla hape ke ho thehoa ha libolo / lifaha tse bohareng ba chip joalokaha ho ka bonoa ka tlase.Tharollo ea sekoli sena ke ho fetola moralo oa stencil -lintlha tse ling li ka bonoa mona.

Ho phodisaSena ke feela mohato oo kopano e pholisoang ka oona empa ke habohlokoa hore ho se ke ha pholisoa kopano ka potlako - hangata tekanyo e khothaletsoang ea ho pholisa ha ea lokela ho feta 3ºC/motsotsoana.

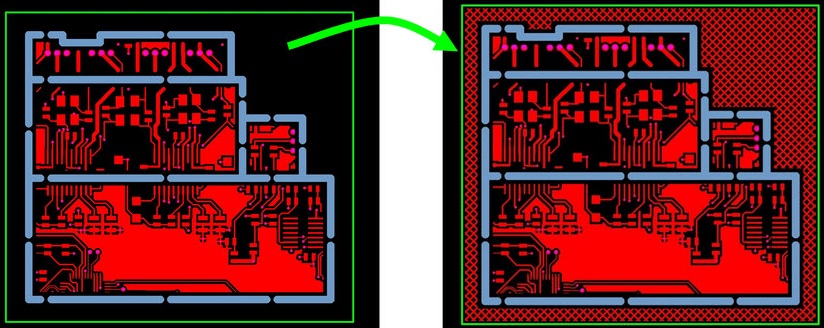

PCB / Component Footprint Design

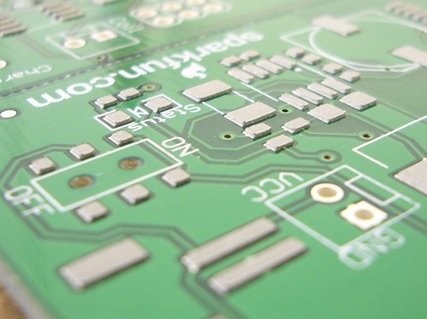

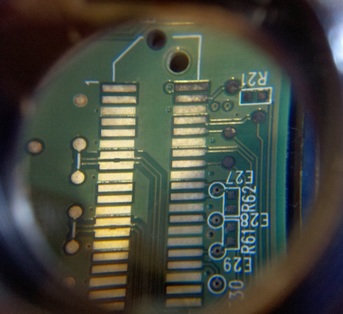

PCB e hatisitsoeng ka hloko ho sebelisoa stencil e entsoeng hantle

Ho beoa ho phetoang ha likarolo tsa holim'a thaba

Mananeo a ho beha likarolo a ka bōptjoa ho sebelisoa mochine oa ho khetha le ho beha empa mokhoa ona ha oa nepahala joaloka ho nka boitsebiso ba centroid ka ho toba ho data ea PCB Gerber.Hangata data ena ea centroid e romelloa kantle ho naha ho tsoa ho software ea moralo ea PCB empa ka nako e 'ngoe ha e fumanehetšebeletso ea ho hlahisa faele ea centroid ho data ea Gerber e fanoa ke Surface Mount Process.

Mechini eohle e behang likarolo e tla ba le 'Pono ea Maemo' e boletsoeng joalo ka:-

35um (QFPs) ho isa ho 60um (chips) @ 3 sigma

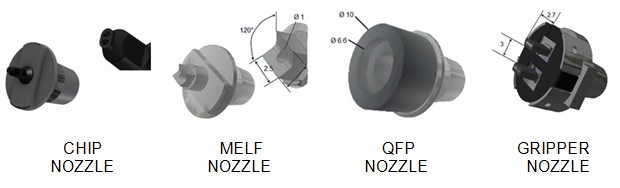

Ho bohlokoa hape hore ho khethoe molomo o nepahetseng bakeng sa mofuta oa motsoako o lokelang ho beoa - mefuta e mengata e fapaneng ea li-nozzle e ka bonoa ka tlase:

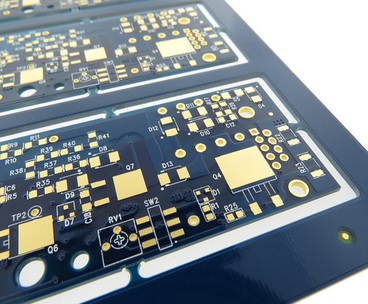

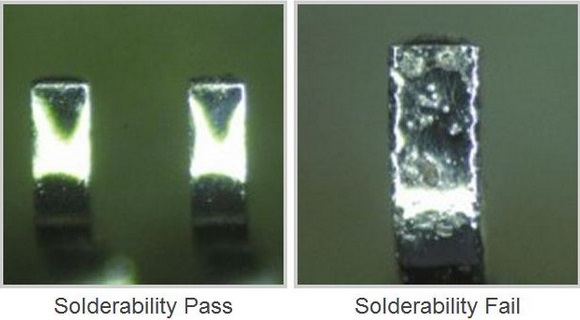

PCB ea boleng bo botle, likarolo le peista ea solder

Nako ea poso: Jun-14-2022