Sebopeho

Likaroloana:

1. Ho sebelisa micro electromagnetic pump tin sebōpi, leqhubu la tin le phahame, phallo e kholo, tlhōrō ea maqhubu e tsitsitse, botebo ba ho kenella ha motsoako oa solder bo boholo, 'me matla a ho kolobisa le a soldering a matla.

2. The periphery ea nozzle le bokaholimo ba solder li sirelelitsoe ka ho tlatsoa ha naetrojene, e ka ntlafatsang ho solderability ea solder e se nang lead, ho fokotsa palo ea tin slag e hlahisoang, ho thibela molomo ho koala, le ho boloka litšenyehelo tsa welding le mosebetsi. litšenyehelo.

3. Ho hanyetsa mocheso o phahameng, ho hanyetsa kutu le nozzle e ikhethang, khanyetso e matla ea oxidation, mongobo o motle, nako e tloaelehileng ea tšebeliso e ka fihla likhoeli tse 3.

4. Iketsetse ka tsela e iketsang boemo ba mokelikeli oa solder ho netefatsa hore ho na le litlhōrō tse tsitsitseng tsa maqhubu.

5. E na le solder joint slimming tshebetso.

6. E tla ka mokhoa o tloaelehileng ka lik'hamera tse peli tsa CCD ho beha leihlo boemo ba ho tjheseletsa le lenaneo la boemo ba PCB.

Kakaretso ea melemo ea lenaneo:

n Kaofela mochining o le mong, canamohela3 liboto kapa3 pallet, e 'ngoe ka spray flux, e' ngoe e preheating, e 'ngoe ka soldering, fumana chai e kholoanyane ea tlhahiso.

n Tafole ea ho fafatsa ka motho ka mong le tafole ea solder.

n Boleng bo phahameng ba solder.

n SMEMA khokahanong ea mohala e khonang.

n Taolo e felletseng ea PC.Mekhahlelo eohle e ka beoa ho PC mme ea bolokoa ho menu ea PCB, joalo ka tsela e tsamaeang, mocheso oa solder, mofuta oa flux, mofuta oa solder,N2thempereichara joalo-joalo, bokhoni bo botle ba ho latela mohlala 'me ho bonolo ho fumana boleng ba solder.

Karolo ea 1: Software

- Sistimi eohle ea software e ntlafalitsoeng ke k'hamphani e tsoang USA, e nang le boiphihlelo ba lilemo tse 8 mabapi le ho khetha, e thehiloeng ho sistimi ea Windows7, e nang le bokhoni bo botle ba ho latela mohlala.

- Sebelisa setšoantšo se hlahlobiloeng e le bokamorao bakeng sa lenaneo la tsela, lebelo le tsamaeang, nako ea ho lula, lebelo le se nang letho, bophahamo ba Z, bophahamo ba maqhubu joalo-joalo kaofela li etselitsoe sebaka sa marang-rang se fapaneng.

- Hlahisa ts'ebetso ea solder ka khamera e hlahang.

- Mekhahlelo ea bohlokoa e tlas'a leihlo ka botlalo ke software ea PC, joalo ka mocheso, lebelo, khatello joalo-joalo.

- E ka ntlafatsoa hore e be le ts'ebetso ea calibration ea auto wave height, ho lekola le ho lekanya wave's bophahamo ka mor'a hore mong le e mong pcb itseng, kahoo ho boloka e ntle haholo botsitso ba leqhubu.

- Mabapi le PCB's mochining oa solder, tlhaiso-leseling eohle e tla bolokoa faeleng e le 'ngoe.E tla kenyelletsa boholo ba PCB le setšoantšo, mofuta oa flux o sebelisitsoeng, mofuta oa solder, mofuta oa solder nozzle, mocheso oa solder, mocheso oa N2, tsela ea motsamao le sebaka ka seng.'s amanang leqhubu bophahamo le Z bophahamo joalo-joalo Ha moreki ho solder tšoanang PCB, ba ka fumana boitsebiso bo feletseng mabapi le kamoo e's etsoa historing, hape ho bonolo bakeng sa mohlala.

Karolo ea 2: Sistimi ea motsamao

- Tafole ea boithaopo e nang le aluminium e entsoeng ka tšepe, boima bo bobebe ka lebelo le potlakileng la ho sisinyeha.

-

Panasonic servo motor & driver fana ka matla a ho khanna a tsitsitseng, ka screw pole & linear guild seporo bakeng sa tataiso.Boemo ba bohlokoa, lerata le fokolang, motsamao o tsitsitseng.

- Ka poleiti e thibelang lerole ka holim'a tafole e sisinyehang, kahoo ho qoba flux kapa solder drop ho senya screw ea bolo.

Karolo ea 3: Sistimi ea fluxing

- Tekanyetso e nang le li-valve tsa jet tse tsoang kantle ho naha ho fumana sephetho sa boleng bo holimo se nang le letheba le lenyane la flux, ka kopo hlokomela hore litaba tse tiileng ha lia lokela ho ba ka tlase ho 10%.

- Flux e na le tanka ea khatello ea polasetiki ea PP, etsa bonnete ba hore khatello e tsitsitse ntle le tšusumetso ea bongata ba phallo.

Karolo ea 4: Preheat

- Ho conveyor top & bottm e nang le preheating ea IR.Boemo bo ka fetoha.

- Karolelano ea mocheso e ka fetoloa ke PC, ho tloha 0 ---100%

Karolo ea 5: pitsa ea solder e habeli

- MABELISisteme ea pitsa ea solder e nang le taolo ea mocheso oa motho ka mong, taolo ea mocheso oa N2, taolo ea bophahamo ba maqhubu.Tsohle li kentsoe tafoleng e le 'ngoe.Sebaka se pakeng tsa lipitsa tse peli tsa solder se ka fetoloa.

- Thempereichara ea solder, mocheso oa N2, bophahamo ba maqhubu, calibration ea wave joalo-joalo kaofela li khona ho kenya software.

- Pitsa ea solder e entsoe ka Ti, eseng ho lutla.E na le heater ea tšepe ka ntle, e matla ebile e chesa ka potlako.

- Pitsa ea solder e hoketsoe ka sehokelo se potlakileng.Ha o fapanyetsana pitsa ea solder ntle le hore o boele o kenye likhoele, feela plug & play.

- Sistimi ea ho futhumatsa ea N2 inthaneteng, ho kolobisa solder ka mokhoa o phethahetseng le ho fokotsa manya a solder.

- Ka ho hlahloba boemo ba solder & alamo.

Karolo ea 6: conveyor

- Stepper motor drive bakeng sa conveyor e tsitsitseng le e tsamaeang.

- E na le rolara ea tšepe e sa hloekang bakeng sa conveyor, e ke keng ea aparoa ka tšebeliso ea nako e telele.Hape etsa bonnete ba hore nozzle ea solder e ka atamela boto'bolelele ba 3mm.

- Ka PCB clamping sistimi ho conveyor.

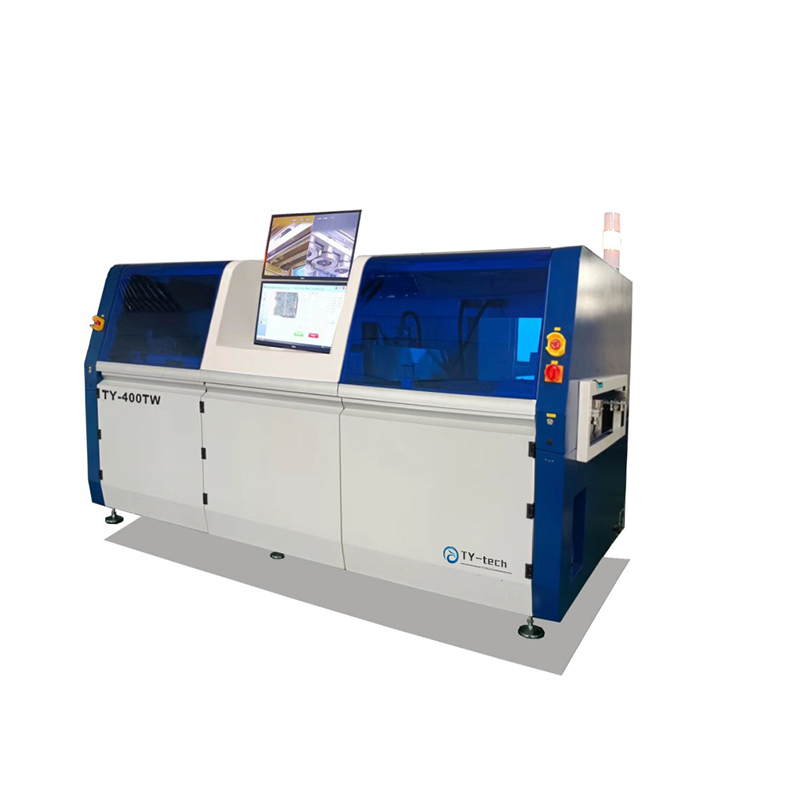

Setšoantšo se qaqileng

Litlhaloso

| Mohlala | TY-400TW-2 |

| Kakaretso | |

| Boemo | L3100 * W1650 * H1650mm |

| Kakaretso ea matla | 28kw |

| Tšebeliso ea matla | 6--10kw |

| Phepelo ea motlakase | Sistimi ea terata ea mekhahlelo e meraro ea 380V |

| Boima bo kahare | 350KG |

| Mohloli oa moea o hlokahalang | 3-5 Libara |

| Phallo ea moea e hlokahalang | 8-12L/min |

| Ho hlokahala khatello ea N2 | 3-4 Libara |

| Phallo e hlokahalang ea N2 | > 4 cubic metres ka hora |

| E hlokehang N2 bohloeki | 》99.998% |

| Ho hloka matla | Ka holimo ho spray: 800---1000cbm/h Ka holim'a sebōpi sa thini: 600---800cbm/h |

| Csebapali kapa PCB | |

| Mojari | Ho hlokahala |

| Boholo ba PCB | L450 * W230MM*2 Tlhokomeliso: W ke tataiso ea bophara ba mochini |

| Boholo bo fokolang ba mopalami | L450 * W450MM Tlhokomeliso: W ke tataiso ea bophara ba mochini |

| Sebaka se seholo sa solder | L500 * W230MM * 2 Tlhokomeliso: W ke tataiso ea bophara ba mochini |

| PCb moeli | 3mm kapa ho feta |

| Controlling & conveyor | |

| Ho laola | PLC + molaoli |

| Bophara ba conveyor | 300-600MM |

| Mofuta oa conveyor | Pin chain conveyor bakeng sa fluxing & preheating, rolara conveyor bakeng sa soldering |

| Conveyor e tenya | 1----4mm |

| Tataiso ea conveyor | Ho tloha ho le letšehali ho ea ho le letona |

| Kopo ea ho tsamaisa thepa | 100MM |

| Conveyor tlase clearance | 30MM |

| Mojaro oa conveyor | <10kg |

| Seporo sa conveyor | Seporo sa aluminium |

| Bophahamo ba conveyor | 900+/-30mm |

| Tafole ya tshisinyo(ho phalla) | |

| Motsamao oa motsamao | X, Y |

| Taolo ya motsamao | Taolo ea servo |

| Ho nepahala ha boemo | +/ - 0.05 limilimithara |

| Chassis | tjheseletsa ka tshepe |

| Tsamaiso ea phallo | |

| Nozzle ea flux | jete valve |

| Nozzle durability | ts'epe e sa beng le mabali |

| Bokhoni ba tanka ea Flux | 1L |

| Tanka ea metsi | tanka ea khatello |

| Preheat | |

| Preheat mokhoa | ho futhumatsa IR holimo le tlase |

| Matla a heater | 16kw |

| Boemo ba mocheso | 25--240c likhato |

| Tafole ea Motion(Soldering) | |

| Motsamao oa motsamao | X, Y, Z |

| Taolo ya motsamao | taolo ea servo |

| Enjene e tsamaeang | Panasonic servo motor |

| Sekoti sa bolo | Hiwin |

| Ho nepahala ha boemo | +/ - 0.05 limilimithara |

| Chassis | Ho chesoa ka tšepe |

| Spitsa e kgolohadi | |

| Nomoro ea pitsa e tloaelehileng | 2 |

| Bophahamo ba pitsa ea solder | 13kg/pitsa*2 |

| Mocheso oa mocheso oa solder | PID |

| Nako ea ho qhibiliha | 60--70 Metsotso |

| Mocheso o moholo oa solder | 350 ℃ |

| Solder heater | 1.2kw*2 |

| Smolomo o moholo | |

| Nozzle e fifala | customized |

| Lintho tse bonahalang | motsoako o phahameng oa carbon |

| Nozzle e tloaelehileng e nang le lisebelisoa | Tlhophiso e tloaelehileng: likotoana tse 5 / sebōpi (bophara bo ka hare 3mm, 4mm, 5mm, 6mm, 8mm) |

| Tsamaiso ea N2 | |

| N2 heater | maemo a hlomelloa |

| Naetrojene PID e laola mofuta oa mocheso oa N2 | 0 - 350 ℃ |

| Tšebeliso ea N2 | 1-2m3/h/pot kakaretso: 4 m3/h |

-

8 Heating Zones High Quality Reflow Soldering O...

-

Mochini oa Tlhahlobo oa Mirtec 3D Inline SPI MS-11

-

PCBA Cleaning Machine Bakeng sa SMT Machine Line PCB ...

-

Hanwha Multi Functional Chip Mounter HM520W

-

Mohala oa Tlhahiso ea Wave Soldering Insertion 2.4M

-

China Wholesales Reflow Oven, SMT Reflow Solder...