Feature

SIPLACE X-Series S Machine description

Intelligent placement solutions for maximum standards

Maximum flexibility, top performance or placement quality: The SIPLACE X-Series Shas state-of-the-art technology to master any challenge arising in SMT production. It offers all the innovations and features to ensure efficient electronics production today and in the future, and provides previously unavailable ways to increase both efficiency and productivity.

Maximum modularity for every need

The compact design of the SIPLACE X-Series S forms the ideal basis for new, future-oriented production concepts which keep pace with dynamically developing customer requirements, without the need for time-consuming conversion as in traditional SMT production lines.

The X-Series S placement machines are available in four different variants

• SIPLACE X2 S (520210)

• SIPLACE X3 S (520310)

• SIPLACE X4 S (520480)

• SIPLACE X4i S (520440)

The numbers in the type name indicate the number of gantries used. Each gantry has one placement head. The SIPLACE X-Series S covers the entire range of common components with only three placement heads.

The placement head CPP is now available as the ideal addition to the well-established placement head TWIN and the ultra-fast placement head CP20 P2.

The user benefits from different PCB conveyor variants:The single conveyor and the flexible dual conveyor.

Board conveyor Placement modes

Synchronous mode in synchronous mode, two boards are transported into the placement position at the same time. They are proessed as a common panel.

When using products with greatly differing placement content, common optimization increases the performance of the whole contention both boards.

Asynchronous mode

In asynchronous mode, only one board is processed on one of the conveyor lanes. At the same time, another board on the second conveyor lane is moved into the placement position. This saves the full conveying time of one board, thus consider ably increasing performance, particularly for boards with a short cycle time.

I-Placement

The SIPLACE line achieves top placement performance with the use of I-Placement. In this mode, the two heads work simultaneously and populate the PCB on the corresponding conveyor side, totally independently of one another. Short distances further increase the output.

Borrow Performance.

By facilitating simultaneous production of two boards with different contents in one line, Borrow Performance is the ideal addition to I-Placement. In placement machines with Borrow Performance, both heads place the same board in alternation The board inthe other conveyor lane is simply transported through the system. This makes it possible to achieve the same cycle time for both boards, despite the different placement contents.

Detail Image

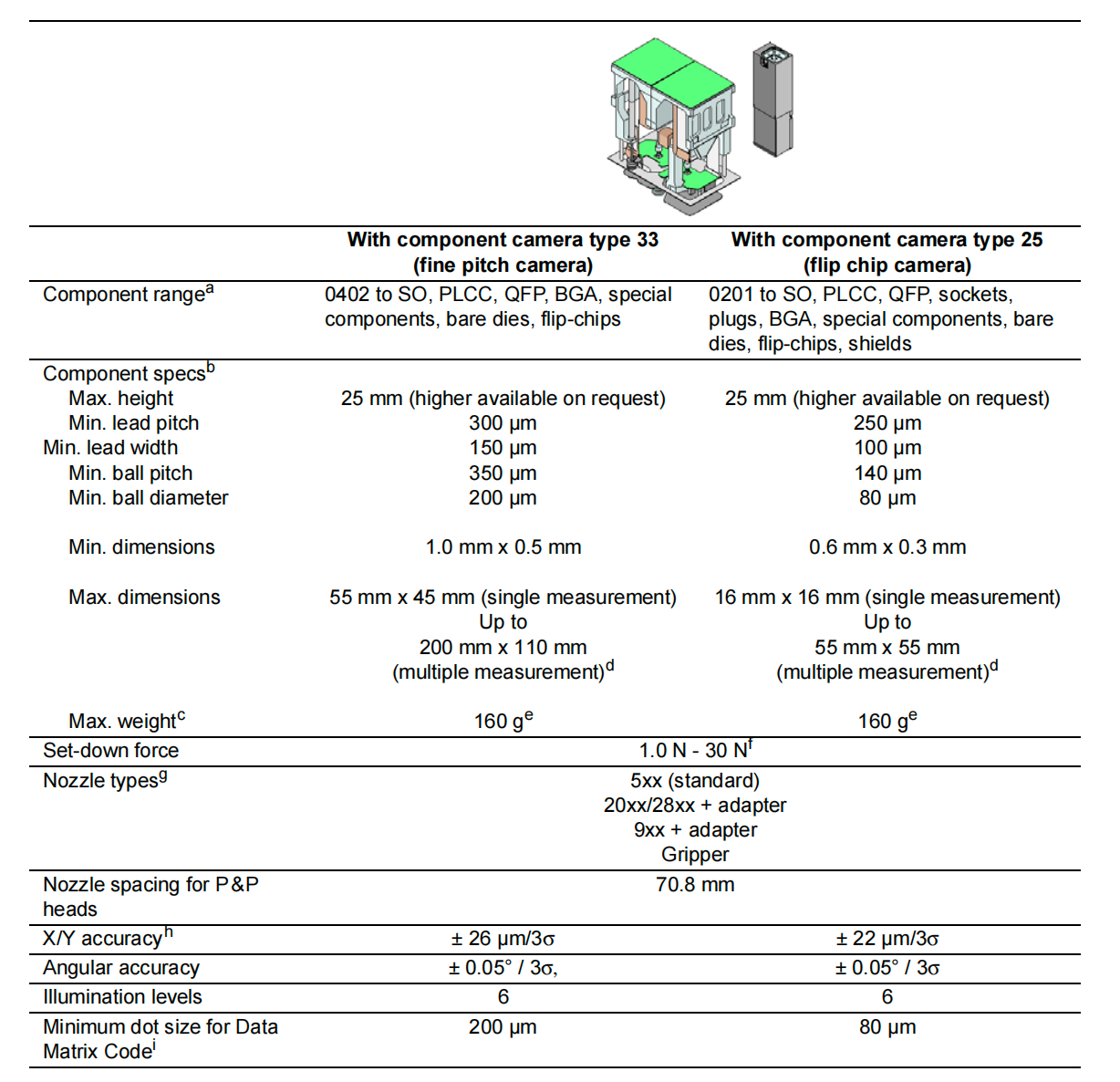

Specifications