Feature

Equipment detection function mechanism description

1. Multi-angle detection function: the ray source + FPD rotate concentrically, and the platform is horizontal and does not tilt

2. Maximum tilt angle between X-ray tube and FPD: 60°

This method is a multi-angle detection method upgraded from the previous two methods of platform tilting and the detector tilting while the ray source is stationary. The advantages are:

a. It is easier to operate than the platform tilting method. It does not need to fix the product, there is no risk of falling, the detection range remains unchanged when the angle is changed, and there is no risk of collision between the radiation source and the platform.

b. It makes better use of the central ray of the ray source than the method of tilting the detector while keeping the ray source stationary. When changing the angle for detection, the central ray of the ray source is always irradiated, the intensity does not decrease, and no distortion or distortion occurs.

3. The optional stage can be rotated 360° horizontally, and used with the 60° tilt function of the X-ray source and detector, making detection more convenient and intuitive.

Feature:

1. 90KV radiation source

2. High resolution digital flat panel detector (FPD)

3. One-key navigation, convenient and fast operation

4. Six-axis linkage control system

5. Optional stage horizontal 360° rotation function

6. Industry-leading multi-angle detection function: (no distortion, no energy loss, no compression of detection range)

7. Maximum tilt angle 60°

8. Stage size: 550mm*450mm

9. Multiple types of measurement functions (distance, diameter, void ratio, solder creep height, etc.)、

10. Multi-point CNC editing and positioning function

11. Test point step NG, OK marking

Detail Image

Specifications

|

Technical Parameters |

||

|

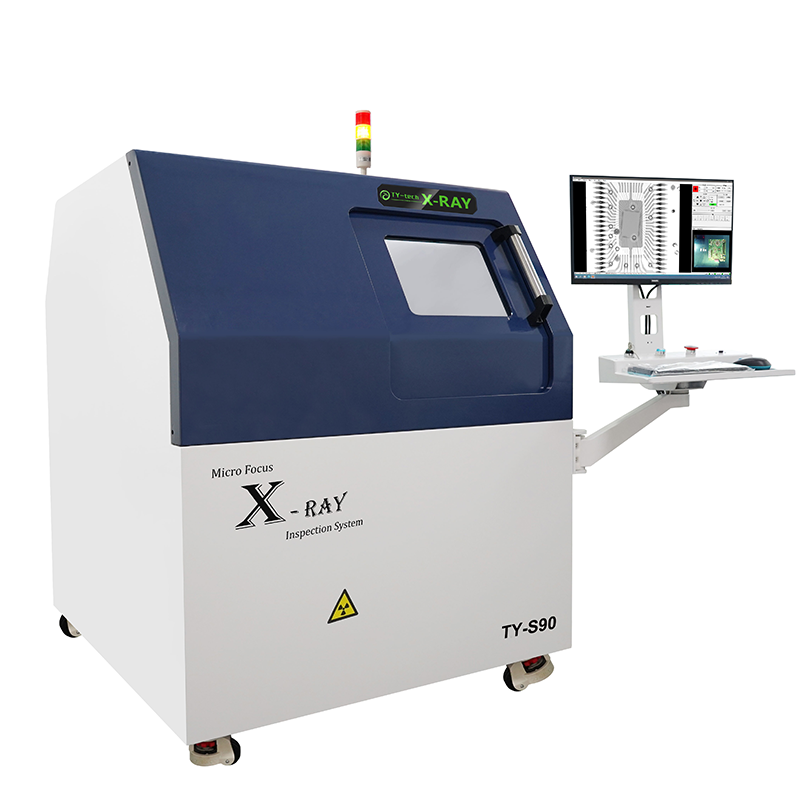

Model |

TY-S90 |

|

|

Main technical indicators |

X-ray tube |

X-ray tube type: Microfocus sealed tube |

| X-ray tube maximum voltage: 90KV | ||

| X-ray tube maximum current: 200UA | ||

| X-ray tube focal size: 5μm | ||

| X-ray tube power: 8W | ||

|

Detector |

Detector Type: High-resolution digital flat panel detector (FPD) | |

| Detector resolution: 5.8LP/mm | ||

| Detector pixel size: 85μm | ||

| Pixel matrix: 1536*1536 | ||

| Image size: 130mm*130mm | ||

| Frame rate: 20fps | ||

| AD conversion bit: 16bit | ||

|

Multi-angle detection function |

Multi-angle detection function: the ray source + FPD rotate concentrically, and the platform is horizontal and does not tilt; | |

| Maximum tilt angle between X-ray tube and FPD: 60° | ||

|

Stage |

Stage size: 550mm*450mm

(When equipped with 360° horizontal rotation function, the stage size is Φ450mm) |

|

| Maximum load-bearing weight of the loading platform: 10KG | ||

|

Machine parameters |

Equipment dimensions: 1200mm (L)*1210mm (W)*1460mm (H) | |

| Equipment weight: about 1000kg | ||

| Power supply: 220VAC, 50/60Hz | ||

| Working environment: 0℃~40℃ / 30~85RH | ||

| Equipment power: 1.3KW | ||

|

Industrial Computer |

Industrial computer operating system: Win10 | |

| Industrial computer memory: 8GB | ||

| Industrial computer hard disk capacity: 1TB | ||

| Monitor: 24-inch widescreen monitor | ||

| Control method: mouse, keyboard | ||

|

Safety interlock function |

Equipment door safety interlock anti-fool measures: If the door is not closed, the X-ray cannot be started / When the X-ray is started, the front door will be automatically locked and cannot be opened / When the X-ray is started, if the door is forced to open by external force, the X-ray will be forced to shut down before the door is opened | |

|

Software Features |

Image processing software: self-developed multifunctional image processing system | |

| Software language: Chinese/English one-click switch | ||

| Navigation system: HD automatic navigation plus real-time location tracking function, accurately and quickly move to the selected test point | ||

| Multi-point editing function: Position editing and saving of location programs based on multi-product measurements, which can be called up at any time. More than 1,000 models can be added and saved based on product requirements. | ||

| Test point step NG, OK marking: When automatically moving the test according to the edited program, you can choose to move at intervals or personnel judge NG, and then proceed to the next point test after OK, which effectively prevents personnel from missing inspections | ||

| Different colors are used to record the position information of the judgment points: When the automatic positioning test is performed according to the edited program, the judgment results are recorded with different colors on the simulated position diagram according to the judgment results of the operator, which is convenient for selection. | ||

| Software measurement functions: void calculation, three-point diameter measurement, parallel distance measurement, polygon measurement function | ||

| Software annotation function: arrow standard, text annotation standard | ||

| Software 3-level authority management: administrator, engineer, operator | ||

|

Radiation safety |

X-ray leakage: ﹤1μSv/h | |