Feature

Features

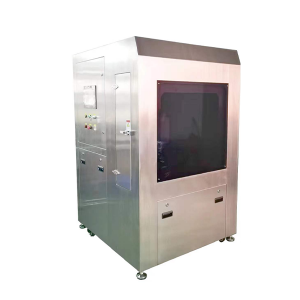

The TY-5500 online PCBA water-based cleaning machine is a cost-effective batch cleaning system that can remove various residues in electronic products, including but not limited to: water-soluble residues, RMA (medium active rosin), no-rinse residues Lead flux, plating salt, fingerprints, dust and loose solder balls, etc. This cleaning machine is designed using the American TDC online medium, low pressure and large flow cleaning process concept. It has the characteristics of high cleaning efficiency and low cost. The nozzles and nozzles are all designed with humanization and are easy to install and maintain.

Machine Feetures

1. PLC+touch screen friendly man-machine platform.

2. Adopting online production method, high efficiency and stable product quality.

3. Adopting the working design principle of medium and low pressure and large flow, it saves cleaning agent consumption, reduces the use cost of production consumables, and has economical and efficient cleaning capabilities.

4. Integrated design, with high scalability, flexible line assembly, and high cost performance, suitable for customer requirements with different production capacity needs.

5. The whole machine is made of corrosion-resistant PP material and is durable.

6. The nozzle adopts quick connector method.

7. The nozzles are made of polyethylene, with dense nozzle arrangement, medium and low pressure, uniform flow and large flow rate.

8. The angle and height of the wind knife are adjustable, and the wind cutting efficiency is high and the noise is low.

9. Optional chemical proportioning system with quantitative automatic rehydration function.

10. The structure adopts humanistic design, such as fans, filters, etc., are reserved for installation and maintenance, which is convenient for repair and maintenance.

Cleaning process

TY-5500 online water-based cleaning machine is divided into three process sections, such as chemical washing and cleaning section, pure water rinsing section and powerful hot air drying section. The whole machine is divided into isolation or chemical pre-cleaning, chemical cycle cleaning, isolation air cutting, Rinse and isolate, isolate air knife DI pre-wash, DI water circulation rinse, final clean water wash, one-stage air cutting and air drying, two stages of air cutting and air drying, three stages of air cutting and air drying, and plate out.

Detailed cleaning process: entering the board → entering the board and isolating → chemical washing one → chemical washing two → isolating → air cutting and isolating → flushing and isolating → air knife isolating → DI water pre-rinsing → DI water rinse one → DI water rinse two → final rinse →Isolation→One stage of high-pressure hot air→Second stage of high-pressure hot air→Three stages of high-pressure hot air→Plate out

Detail Image

Specifications

| Project name | Technical indicators | |

|

1 |

Machine dimension | L5500*W1600*H1620mm |

|

2 |

Power | ~115kw |

|

3 |

Cleaning product size | 2000mm(L)*500mm(W)*80mm(H) |

|

4 |

Cleaning fluid consumption | 1.0-2.5L/H |

|

5 |

DI water consumption | 5L-10L/min |

|

6 |

Conveyor speed | 10mm/min-1500mm/min |

|

7 |

Control method | Touch screen + PLC control |

|

8 |

Body material | Corrosion-resistant imported PP material |

|

9 |

Mesh belt material | Stainless steel SUS316 |

|

10 |

Air source requirements | 0.4-0.7(Mpa) |

|

11 |

Power requirements | 3PH, 380 VAC, 5 wires |

|

12 |

Weight | ~2200kg |

|

13 |

DI water quality requirements | >15MΩ (Depending on customer products) |

|

14 |

DI water inlet requirements | 1.0 m3/h |

|

15 |

Exhaust air volume requirements | 1200 CFM |

|

16 |

Noise | < 70 Db |

|

17 |

Chemical washing area spray pressure | 25-50psi |

|

18 |

DI rinse zone spray pressure | 25-50psi |

|

19 |

Product weight | <10kg |

|

20 |

Water tank temperature in chemical washing section | 25-75℃ |

|

21 |

Wind knife angle | Angle adjustable, lift adjustable |

|

22 |

Nozzle installation method | Quick connector method for easy replacement |

|

24 |

Belt width | 500mm, customizable |

|

25 |

Water pipe installation method | Quick connection method for easy maintenance |

|

26 |

Filtration precision (level 3) | Minimum 10μm filter element |