I-Reflow soldering yeyona ndlela isetyenziswa kakhulu yokuncamathelisa amacandelo omgangatho wentaba kwiibhodi zesekethe eziprintiweyo (PCBs).Injongo yale nkqubo kukwenza i-solder eyamkelekileyo ngokufudumeza kuqala amacandelo / i-PCB / i-solder paste kwaye unyibilikise i-solder ngaphandle kokwenza umonakalo ngokufudumeza.

Imiba ephambili ekhokelela kwinkqubo esebenzayo ye-reflow soldering yile ilandelayo:

- Umatshini ofanelekileyo

- Iprofayile eyamkelekileyo yokubuyisela kwakhona

- I-PCB/icandelo lophawu loYilo

- I-PCB eprintwe ngononophelo kusetyenziswa istensile eyilwe kakuhle

- Ukubekwa okuphindaphindiweyo kwamacandelo okunyuka komphezulu

- Umgangatho olungileyo we-PCB, amacandelo kunye ne-solder paste

Umatshini ofanelekileyo

Kukho iintlobo ezahlukeneyo zomatshini wokuphinda udibanise umatshini okhoyo ngokuxhomekeke kwisantya somgca ofunekayo kunye noyilo / izinto zeendibano zePCB eziza kuqhutyelwa phambili.I-oven ekhethiweyo kufuneka ibe yisayizi efanelekileyo yokusingatha izinga lokuvelisa i-pick kunye nendawo yezixhobo.

Isantya somgca singabalwa njengoko kubonisiwe ngezantsi:-

Isantya somgca (ubuncinci) =Iibhodi ngomzuzu x Ubude kwibhodi nganye

Umthwalo weFactor (isithuba phakathi kweebhodi)

Kubalulekile ukuqwalasela ukuphinda-phinda kwenkqubo kwaye ke 'iFactor yomthwalo' idla ngokuchazwa ngumenzi womatshini, ubalo oluboniswe ngezantsi:

Ukuze ukwazi ukukhetha ubungakanani obuchanekileyo be-oveni yokubuyisela kwakhona isantya senkqubo (esichazwe ngezantsi) kufuneka sibe sikhulu kunesantya esincinci esibaliweyo somgca.

Isantya senkqubo =Igumbi le-oveni ubude obushushu

Ixesha lokuhlala kwinkqubo

Apha ngezantsi ngumzekelo wokubala ukuseka ubungakanani obuchanekileyo be-oveni: -

Umhlanganisi we-SMT ufuna ukuvelisa iibhodi ezi-8-intshi ngesantya se-180 ngeyure.Umenzi we-solder paste ucebisa umzuzu we-4, iprofayili yamanyathelo amathathu.I-oveni ifuna ixesha elingakanani ukwenza iibhodi kolu gqibo?

Iibhodi ngomzuzu = 3 (180/yure)

Ubude bebhodi nganye = 8 intshi

Umthwalo weFactor = 0.8 (2-inch space phakathi kweebhodi)

Inkqubo yokuHlala ixesha = imizuzu emi-4

Bala isantya somgca:(3 iibhodi/min) x (8 intshi/ibhodi)

0.8

Isantya somgca = 30 intshi/ngomzuzu

Ngoko ke, i-oven reflow kufuneka ibe nesantya senkqubo ubuncinane ubuncinane be-intshi ezingama-30 ngomzuzu.

Qinisekisa ubude begumbi le-oveni elishushu ngesantya seequation:

30 kwi/min =Igumbi le-oveni ubude obushushu

Imizuzu emi-4

Ubude be-oven eshushu = 120 intshi (10 feet)

Qaphela ukuba ubude obupheleleyo be-oven buya kudlula iinyawo ze-10 kubandakanywa necandelo lokupholisa kunye namacandelo okulayishwa kwe-conveyor.Isibalo sesobude be-Oveni OKUSHISAYO - AYIKHO UBUDE BOKUGQIBELA.

1. Uhlobo lweConveyor – Kuyenzeka ukuba ukhethe umatshini onemesh conveyor kodwa ngokuqhelekileyo i-edge conveyors ichaziwe ukwenzela ukuba i-oven isebenze emgceni kwaye ikwazi ukucubungula iindibano zamacala amabini.Ukongeza kwi-edge conveyor i-center-board-support idla ngokubandakanywa ukumisa i-PCB ekudakaleni ngexesha lenkqubo yokubuyisela kwakhona - jonga ngezantsi.Xa kusetyenzwa iindibano zamacala amabini usebenzisa i-edge conveyor system care kufuneka ithathwe ukuze ingaphazamisi amacandelo angaphantsi.

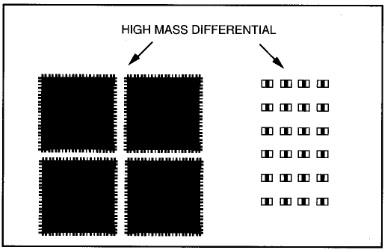

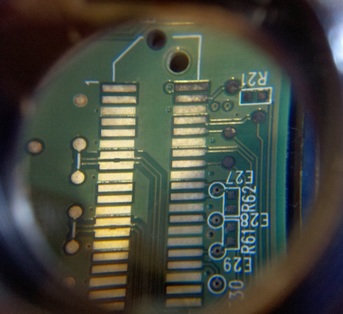

2. Ukulawulwa kwe-loop evaliweyo kwisantya sabalandeli be-convection - Kukho iipakethi ezithile zokunyuka kwendawo efana ne-SOD323 (jonga i-insert) enendawo encinci yokudibanisa kwi-mass ratio enokuthi iphazamiseke ngexesha lenkqubo yokubuyisela kwakhona.Ukulawulwa kwesantya se-loop esivaliweyo sabalandeli bendibano lukhetho olucetyiswayo kwiindibano ezisebenzisa iindawo ezinjalo.

3. Ulawulo oluzenzekelayo lwe-conveyor kunye ne-center-board-support wides - Abanye oomatshini banohlengahlengiso lobubanzi bemanuwali kodwa ukuba kukho iindibano ezininzi ezahlukeneyo eziza kucutshungulwa ngobubanzi obuhlukeneyo bePCB ngoko olu khetho luyacetyiswa ukuba kugcinwe inkqubo engaguqukiyo.

Iprofayile yeReflow eyamkelekileyo

- Uhlobo lwe-solder paste

- Izinto zePCB

- PCB ubukhulu

- Inani leeleya

- Isixa sobhedu ngaphakathi kwePCB

- Inani lamalungu okunyuka komphezulu

- Uhlobo lwamacandelo okunyuka komphezulu

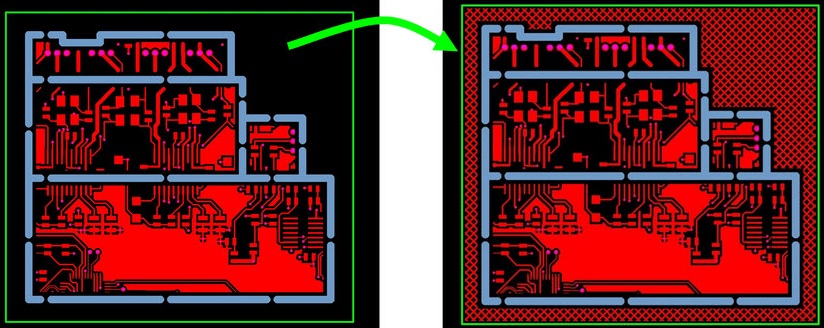

Ukuze udale iprofayile ye-reflow thermocouples idityaniswe kwindibano yesampulu (idla ngokuba ne-solder yobushushu obuphezulu) kwiindawo ezininzi ukulinganisa uluhlu lwamaqondo obushushu kwiPCB.Kuyacetyiswa ukuba ubuncinci ube ne-thermocouple enye ebekwe kwiphedi ukuya kumda wePCB kunye ne-thermocouple enye ebekwe kwipadi ukuya kumbindi wePCB.Ngokunqwenelekayo iithermocouples ezininzi kufuneka zisetyenziswe ukulinganisa uluhlu olupheleleyo lwamaqondo obushushu kwi-PCB yonke – eyaziwa ngokuba yi-'Delta T'.

Ngaphakathi kweprofayili ye-reflow soldering eqhelekileyo kukho izigaba ezine-Preheat, soak, reflow kunye nokupholisa.Eyona njongo iphambili kukudlulisa ubushushu obaneleyo kwindibano ukunyibilikisa i-solder kunye nokwenza i-solder joints ngaphandle kokwenza umonakalo kumacandelo okanye kwi-PCB.

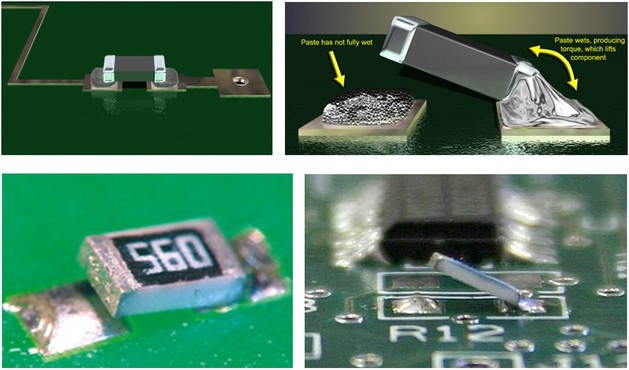

Ukutshisa kwangaphambiliNgeli nqanaba amacandelo, i-PCB kunye ne-solder zonke zifudunyezwa kwi-soak ecacisiweyo okanye iqondo lokushisa elihlala liqaphela ukuba lingafudumeza ngokukhawuleza (ngokuqhelekileyo akukho ngaphezu kwe-2ºC / isibini - khangela i-solder paste yedatha).Ukufudumeza ngokukhawuleza kunokubangela iziphene ezifana nezixhobo zokuqhekeka kunye ne-solder paste kwi-splatter ebangela iibhola ze-solder ngexesha lokuhamba kwakhona.

Zimanzise– Injongo yesi sigaba kukuqinisekisa ukuba onke amacandelo afikelela kwiqondo lobushushu elifunekayo ngaphambi kokungena kwinqanaba lokuphinda liphume.I-Soak idla ngokuhlala phakathi kwemizuzwana engama-60 kunye ne-120 ngokuxhomekeke 'kumahluko wobunzima' wendibano kunye neendidi zamalungu akhoyo.Okusebenzayo ngakumbi ukuhanjiswa kobushushu ngexesha lesigaba sokufunxa ixesha elincinci elifunekayo.

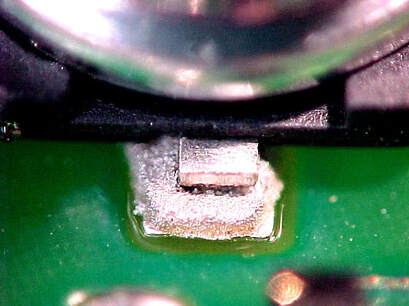

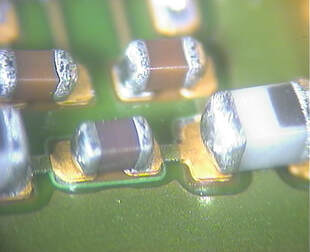

Isiphene esiqhelekileyo sokuthengisa emva kokuhamba kwakhona kukubunjwa kweebhola ze-solder eziphakathi kwe-chip / amaso njengoko kunokubonwa ngezantsi.Isisombululo sesi siphene kukuguqula uyilo lwe-stencil -iinkcukacha ezingaphezulu zinokubonwa apha.

Ukupholisa– Eli linqanaba nje apho indibano ipholiswa khona kodwa kubalulekile ukuba indibano ingapholi ngokukhawuleza kakhulu – ngokuqhelekileyo izinga lokupholisa elicetyiswayo alifanele libe ngaphezu kwe-3ºC/sesibini.

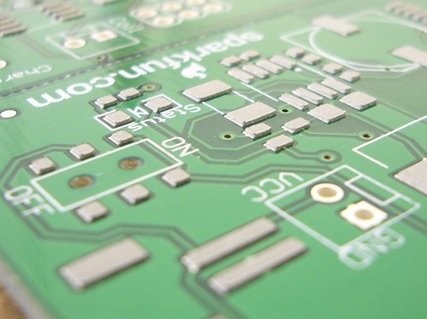

PCB/Component Footprint Design

I-PCB eprintwe ngononophelo kusetyenziswa istensile eyilwe kakuhle

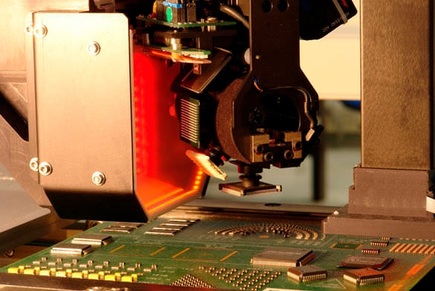

Ukubekwa okuphindaphindiweyo kwamacandelo okunyuka komphezulu

Iinkqubo zokubekwa kwecandelo zinokudalwa kusetyenziswa oomatshini bokuchola kunye nendawo kodwa le nkqubo ayichanekanga njengokuthatha ulwazi lwecentroid ngqo kwidatha yePCB Gerber.Rhoqo le datha ye-centroid ithunyelwa ngaphandle kwisoftware yoyilo yePCB kodwa ngamanye amaxesha ayifumaneki kwaye keinkonzo yokuvelisa ifayile ye-centroid evela kwidatha yeGerber inikezelwa yiNkqubo yeMount Mount.

Bonke oomatshini bokubekwa kwamacandelo baya kuba 'nokuChaneka kokuBeka' okucaciswe ngolu hlobo:-

35um (QFPs) ukuya 60um (iitshiphusi) @ 3 sigma

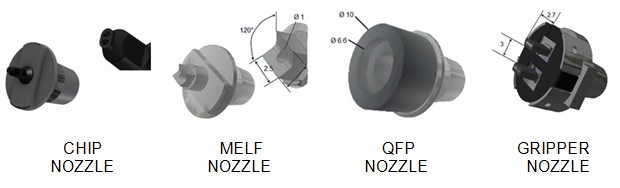

Kukwabalulekile ukuba umlomo wombhobho ochanekileyo ukhethelwe uhlobo lwecandelo eliza kubekwa - uluhlu lwemilomo yamacandelo ahlukeneyo anokubonwa apha ngezantsi:-

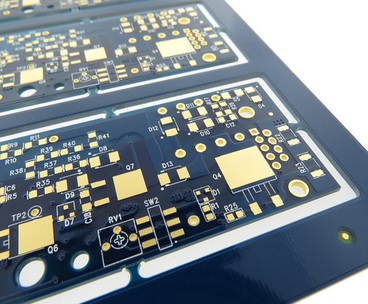

Umgangatho olungileyo we-PCB, amacandelo kunye ne-solder paste

Ixesha lokuposa: Jun-14-2022