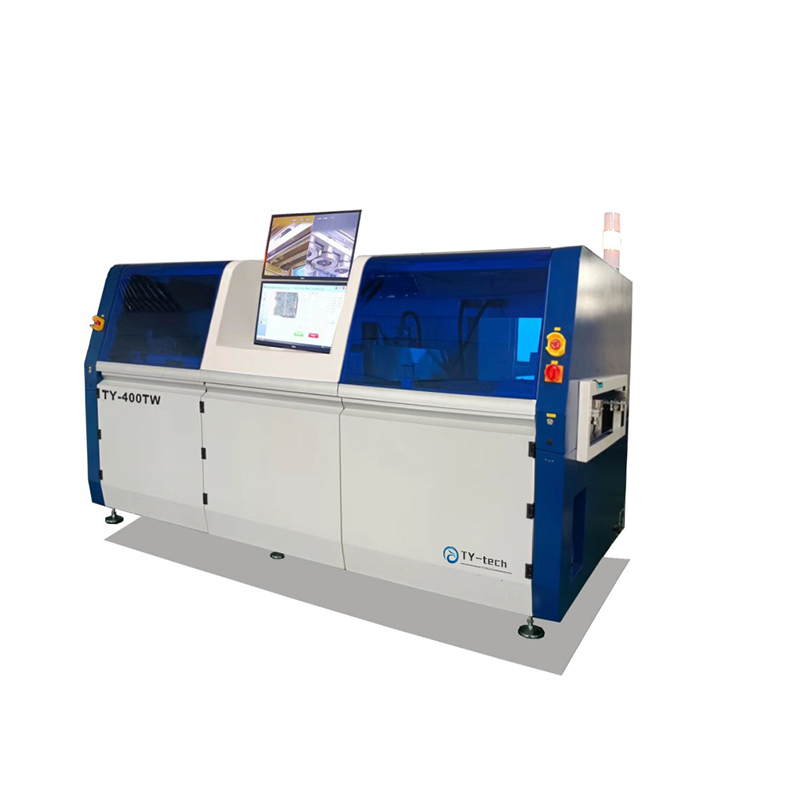

Uphawu

Iimbonakalo:

1. Ukusebenzisa i-micro-electromagnetic pump tin furnace, i-wave ye-tin iphezulu, ukuhamba kukhulu, i-wave wave izinzile, ubunzulu bokungena kwe-solder bukhulu, kwaye amandla okumanzisa kunye ne-solder yomelele.

2. I-periphery ye-nozzle kunye nomphezulu we-solder ikhuselwe ngokuzaliswa kwe-nitrogen, enokuphucula ukuthengiswa kwe-solder-free solder, ukunciphisa umthamo we-tin slag eyenziwe, ukuthintela umlomo ukuba uvale, kwaye ugcine iindleko ze-welding kunye nomsebenzi. iindleko.

3. Ukumelana nokushisa okuphezulu, ukuxhathisa kwe-corrosion kunye ne-nozzle ekhethekileyo, ukuxhathisa okunamandla kwe-oxidation, ukumanzisa okulungileyo, ixesha eliqhelekileyo lokusetyenziswa linokufikelela kwiinyanga ezi-3.

4. Bona ngokuzenzekelayo inqanaba lolwelo lwe-solder ukuqinisekisa iincopho zamaza ezizinzileyo.

5. Inomsebenzi we-solder joint slimming.

6. Iza kumgangatho kunye neekhamera zeCCD ezimbini ukujonga imeko ye-welding kunye ne-PCB yokubeka inkqubo.

Isishwankathelo seenzuzo zeprogram:

n Konke kumatshini omnye, inkonkxaukuhlalisaIibhodi ezi-3 okanye3 i-pallet, enye ikwi-spray flux, enye ifudumeza, enye ikwi-soldering, ifumana isivuno esikhulu semveliso.

n Itheyibhile eguquguqukayo yokutshiza yomntu ngamnye kunye netafile yokuxutywa.

n Umgangatho ophezulu wokusoda.

n SMEMA kuqhagamshelwano olusebenzayo.

n Ulawulo olupheleleyo lwePC.Zonke iiparamitha zinokuseta kwi-PC kwaye zigcinwe kwimenyu ye-PCB, njengokuhamba kwendlela, ubushushu be-solder, uhlobo lwe-flux, uhlobo lwe-solder,N2iqondo lobushushu njl.

Inxalenye1: Isoftware

- Yonke inkqubo yesoftware ephuhliswe yinkampani evela e-USA, kunye neminyaka eyi-8 yamava malunga ne-solder ekhethiweyo, isiseko senkqubo yeWindows7, enobuchule bokulandela umkhondo.

- Sebenzisa umfanekiso oskeniweyo njengemvelaphi yenkqubo yendlela, isantya esihambayo, ixesha lokuhlala, isantya sokushukuma esingenanto, ubude be-Z, ukuphakama kwamaza njl.

- Bonisa inkqubo yokuthengisa ngekhamera ephilayo.

- Iiparamitha ezibalulekileyo ziphantsi kolawulo lwesoftware yePC, njengobushushu, isantya, uxinzelelo njl.

- Inokuthi iphuculwe ukuze ibe nomsebenzi wokulinganisa ubude be-auto wave, ukujonga kunye nokulinganisa amaza's ukuphakama emva kwepcb nganye ethile, ukuze ugcine uzinzo oluhle kakhulu lwamaza.

- Malunga PCB's imenyu kumatshini wokuthengisela, lonke ulwazi luya kugcinwa kwifayile enye.Iya kubandakanya ubukhulu bePCB kunye nomfanekiso, uhlobo olusetyenzisiweyo lwe-flux, uhlobo lwe-solder, uhlobo lwe-nozzle ye-solder, ubushushu be-solder, ubushushu be-N2, indlela yokuhamba kunye nesiza ngasinye.'s enxulumene ukuphakama wave kunye nobude Z etc. Xa umthengi solder PCB efanayo, banokufumana ulwazi olupheleleyo malunga nendlela's kwenziwa kwimbali, kwakhona lula umkhondo.

Icandelo2: inkqubo yentshukumo

- Itafile eshukumayo yoyilo oluzenzelayo enealuminiyam ephosiweyo, ubunzima obukhaphukhaphu kunye nesantya esikhawulezayo sokushukuma.

-

I-Panasonic servo motor kunye nomqhubi ubonelela ngamandla okuqhuba azinzileyo, kunye ne-screw pole kunye ne-linear guild rail kwisikhokelo.Isikhundla esixabisekileyo, ingxolo encinci, intshukumo ezinzileyo.

- Ngepleyiti yobungqina bothuli ngaphezulu kwetafile eshukumayo, ukunqanda ukuguquguquka okanye ukuwisa i-solder ukonakalisa isikrufu sebhola.

Icandelo 3: inkqubo yokuguquguquka

- Umgangatho oxhotyiswe ngevalve yejethi evela kumazwe angaphandle ukufumana iziphumo eziguquguqukayo ezinexabiso elincinci, nceda uqaphele umxholo oqinileyo we-flux kufuneka ube ngaphantsi kwe-10%.

- I-Flux igcinwe yi-PP yeplastiki yetanki yoxinzelelo, qinisekisa ukuba uxinzelelo luzinzile ngaphandle kwefuthe lobungakanani bokuhamba.

Icandelo 4: Ukushisa kwangaphambili

- Kwiconveyor top & bottm ixhotyiswe nge-IR preheating.Isikhundla siyahlengahlengiswa.

- Umlinganiselo wokufudumeza ulungelelaniswa yiPC, ukusuka kwi-0 ---100%

Icandelo 5: imbiza yesoda ezimbini

- MBINIinkqubo imbiza solder kunye nolawulo lobushushu ngamnye, ulawulo lobushushu N2, ulawulo ukuphakama amaza.Zonke zifakwe kwitafile enye.Umgama phakathi kweembiza ezimbini zesolder ungalungiswa.

- Ubushushu be-Solder, ubushushu be-N2, ukuphakama kwamaza, ukulinganisa amaza njl.njl zonke ziyakwazi ukuseta kwisoftware.

- Imbiza yeSolder yenziwe ngeTi, hayi ukuvuza.Kufakwe isifudumezi sentsimbi ngaphandle, ubushushu obuqinileyo kunye nobushushu obukhawulezayo.

- Imbiza yesoda ineentambo kunye nesinxibelelanisi esikhawulezayo.Xa utshintshisa imbiza ye-solder ngaphandle kocingo kwakhona olufunekayo, vele uplagi kwaye udlale.

- Inkqubo yokufudumala ye-N2 kwi-intanethi, ukumanzisa i-soldering ngokugqibeleleyo kunye nokunciphisa inkunkuma ye-solder.

- Ngokujonga inqanaba le-solder kunye ne-alam.

Icandelo 6: umthumeli

- I-Stepper motor drive ye-conveyor ezinzileyo kunye neshukumayo.

- Ngerola yentsimbi engatyiwayo yokuhambisa, ayinxitywa ngokusetyenziswa kwexesha elide.Kwakhona qiniseka ukuba umbhobho we-solder ungasondela ebhodini's edge 3mm.

- Ngenkqubo yokuqinisa iPCB kwindawo yokuhambisa.

Umfanekiso weenkcukacha

Iinkcukacha

| Umzekelo | TY-400TW-2 |

| Ngokubanzi | |

| Ubungakanani | L3100 * W1650 * H1650mm |

| Amandla ngokubanzi | 28kw |

| Amandla okusebenzisa | 6--10kw |

| Ukunikezwa Amandla | Inkqubo ye-five-class ye-380V |

| Ukusinda okushiyekile | 350KG |

| Umthombo womoya ofunekayo | 3-5 Imivalo |

| Ukuhamba komoya okufunekayo | 8-12L/min |

| Uxinzelelo lwe-N2 olufunekayo | 3-4 Imivalo |

| Ukuhamba okufunekayo kwe-N2 | >4 cubic metres ngeyure |

| Ucoceko olufunekayo lwe-N2 | 》99.998% |

| Ukudinwa okufunekayo | Ngaphezulu kwesitshizi: 800---1000cbm/h Ngaphezulu kwesithando somlilo: 600---800cbm/h |

| Cumxhasi okanye PCB | |

| Umthwali | Kuyimfuneko |

| Ubungakanani obukhulu bePCB | L450 * W230MM * 2 Qaphela: W yindlela yobubanzi bomatshini |

| Ubungakanani obuncinci bokuthwala | L450 * W450MM Qaphela: W yindlela yobubanzi bomatshini |

| Indawo yesolder enkulu | L500 * W230MM * 2 Qaphela: W yindlela yobubanzi bomatshini |

| Umda wePcb | 3mm okanye ngaphezulu |

| Cukulawula kunye nokuhambisa | |

| Ukulawula | PLC + umlawuli |

| Ububanzi beConveyor | 300-600MM |

| Uhlobo lomhambisi | Ikhonkco lekhonkco lokuhambisa lokuguquguquka kunye nokufudumeza kwangaphambili, isihambisi serola sokuhambisa |

| Iconveyor engqindilili | 1----4mm |

| Umkhombandlela womhambisi | Ekhohlo ukuya ekunene |

| Imvume yokuhambisa | 100MM |

| Ukucocwa komhambisi ongezantsi | 30MM |

| Umthwalo womthumeli | <10kg |

| Umzila kaloliwe | Isiporo seAluminiyam |

| Ubude beConveyor | 900+/-30mm |

| Itafile eshukumayo(ukuguquguquka) | |

| Umgca wentshukumo | X, Y |

| Ulawulo lwentshukumo | Ulawulo lwe-Servo |

| Ukuchaneka kwesikhundla | + / - 0.05 mm |

| Itshisi | ukuwelda ngentsimbi |

| Ulawulo lweFlux | |

| Flux umlomo | ivalve yejethi |

| Ukuqina kombhobho | yenziwe ngentsimbi eshayinayo |

| Umthamo wetanki ye-Flux | 1L |

| Itanki yeFlux | itanki yoxinzelelo |

| Ukutshisa kwangaphambili | |

| Indlela yokutshisa | ubushushu be-IR ephezulu nasezantsi |

| Amandla okufudumala | 16kw |

| Uluhlu lobushushu | 25--240c isidanga |

| Itafile eshukumayo (i-soldering) | |

| Umgca wentshukumo | X, Y, Z |

| Ulawulo lwentshukumo | ulawulo lwe-servo |

| Imoto eshukumayo | I-Panasonic servo motor |

| Ibhola Screw | Hiwin |

| Ukuchaneka kwesikhundla | + / - 0.05 mm |

| Itshisi | Ukuwelda kwentsimbi |

| Simbiza endala | |

| Inombolo yembiza eqhelekileyo | 2 |

| Umthamo wembiza yesoda | 13kg/imbiza*2 |

| Uluhlu lobushushu beSolder | PID |

| Ixesha lokunyibilika | 60--70 Imizuzu |

| Ubushushu be-solder obuphezulu | 350 ℃ |

| Isifudumezi solder | 1.2kw*2 |

| Sumlomo omdala | |

| Umbhobho umnyama | eyenzelwe wena |

| Izinto eziphathekayo | ialloy yekhabhoni ephezulu |

| Umbhobho oxhotyisiweyo osemgangathweni | Ulungelelwaniso olusemgangathweni: amaqhekeza ama-5 / iziko (ubukhulu bangaphakathi 3mm, 4mm, 5mm, 6mm, 8mm) |

| Ulawulo lwe-N2 | |

| N2 heater | umgangatho unezixhobo |

| Ulawulo lwe-Nitrogen PID ye-N2 yoluhlu lwexesha | 0 - 350 ℃ |

| Ukusetyenziswa kwe-N2 | 1-2m3 / h / imbiza iyonke: 4 m3 / h |

-

Iindawo zokufudumeza ezisi-8 zoMgangatho oPhakamileyo wokuReflowa kwakhona kweSoda O...

-

I-Mirtec 3D Inline SPI yokuhlola uMtshini we-MS-11

-

Umatshini wokuCoca we-PCBA we-SMT Machine Line PCB ...

-

IHanwha Multi Functional Chip Mounter HM520W

-

I-Wave Soldering Insertion Production Line 2.4M

-

I-Oven ye-Wholesales Reflow yaseTshayina, i-SMT Reflow Solder...