Uphawu

1. Ikhompyutheni ye-Brand LCD + i-PLC inkqubo yokulawula ingqiqo iyamkelwa, ngokuchaneka kokulawula ukushisa okuphezulu kwe-± 1 ° C (ukuba ikhomputha iphazamiseka ngokungalindelekanga, umsebenzi ongekho kwi-intanethi ungenziwa ngaphandle kokuchaphazela imveliso), ukuqinisekisa ukuzinza nokuthembeka kwenkqubo yokulawula. ;

2. I-interface yokusebenza ye-Windows7, inamandla kwaye kulula ukuyisebenzisa;

3. Ukuvulwa kwesithando somlilo esiphezulu kwamkela oomatshini abaphindwe kabini bombane ukuze kuqinisekiswe ukhuseleko nokuthembeka;

4. Ixhotyiswe ngesixhobo sokuqinisa ibhanti, uthutho luzinzile, alushukumi, alunakuguqulwa, luqinisekisa ukuthuthwa okugudileyo kwePCB;

5. Indlela yokuhanjiswa komzila kaloliwe ye-synchronous (inokudityaniswa kwi-intanethi kunye nomatshini wokubeka ngokuzenzekelayo) ukuze kuqinisekiswe uhlengahlengiso oluchanekileyo lwesikhokelo sobubanzi bomzila kaloliwe kunye nobomi benkonzo ephezulu;(uloliwe ozikhethelayo)

6. Ukulawula ngokuzenzekelayo inkqubo yokuthambisa, enokuthi ifake i-lubricate chain chain transmission ngokubeka ixesha lokufaka i-refueling kunye nexabiso le-refueling;

7. Zonke iindawo zokufudumeza ziyi-PID elawulwa yikhompyutheni (imimandla yeqondo lokushisa inokuvulwa ngokwahlukileyo. Ukufudumala kunokwahlula kwiindawo zokunciphisa amandla okuqala);

8. Uthungelwano lwenethiwekhi/yetsheyini luvalwe ngokupheleleyo olulawulwa yikhompyutha, olunokuhlangabezana nokuveliswa ngaxeshanye kweentlobo ezahlukeneyo zePCB;

9. Ngesandi esinempazamo kunye nomsebenzi wokukhanya okhanyayo;

10. Ukuxhotyiswa ngomkhuseli wokuvuza ukuqinisekisa ukhuseleko lwabaqhubi kunye nenkqubo yokulawula;

11. I-UPS eyakhelwe-ngaphakathi kunye nenkqubo yokulibaziseka ngokuzenzekelayo ukuze kuqinisekiswe ukuba i-PCB kunye nomatshini we-reflow soldering awuyi konakaliswa xa umbane ucinyiwe okanye ushushu;

12. Yamkela i-HELLER indlela yokufudumala yokufudumala i-air circulation, i-high-efficiency pressurized acceleration air duct, ukwandisa kakhulu ukuhamba komoya oshushu ojikelezayo, ukunyuka kweqondo lokushisa ngokukhawuleza (malunga nemizuzu eyi-10), ukusebenza kakuhle kwembuyekezo ye-thermal, kunye ne-welding ephezulu yokushisa kunye nokunyanga;

13. Ummandla weqondo lokushisa uxhotyiswe nge-sensor yokuvavanya ubushushu obuzimeleyo ukubeka iliso kunye nokuhlawulela ibhalansi yeqondo lokushisa kwindawo nganye yokushisa ngexesha langempela;

14. Inkqubo yokusebenza kunye nokulawulwa kwephasiwedi ivimbela abasebenzi abangahambelaniyo ekutshintsheni iiparitha zenkqubo, kwaye ulawulo lwerekhodi lokusebenza lunokulandelela inkqubo yokutshintsha iiparitha zenkqubo, efanelekileyo ekuphuculeni ulawulo.Inokugcina isantya sobushushu esikhoyo somsebenzisi kunye nejiko lobushushu phantsi kocwangciso, kwaye inokutshintsha yonke idatha yoShicilelo kunye neegophe;

15. Ifestile yokulawula edibeneyo, i-computer switch, i-curve yokuvavanya, i-curve yokuprinta kunye nokuhanjiswa kwedatha konke kulula ukuyisebenzisa, kwaye uyilo lwenziwa ngabantu.Ixhotyiswe ngenkqubo yokuvavanya i-intanethi ye-channel ye-curve ye-curve ye-intanethi, ekwazi ukubona i-curve yangempela yokushisa ye-welding into naliphi na ixesha (akukho mfuneko yokuqwalasela umhloli we-curve wokushisa);

16. Inkqubo yokupholisa ngokukhawuleza evela kubuchwepheshe bamazwe ngamazwe ithatha ukukhulisa uhlobo lweglasi oluphakathi kunye nokupholisa ngokukhawuleza okusebenzayo, isantya sokupholisa sinokufikelela kwi-3.5 ~ 6 ° C / sec, kwaye ulawulo lulula kakhulu;isixhobo sokupholisa ngenkani sangaphandle siqinisekisa umphumo we-crystallization we-solder joints (Ukhetho olukhethiweyo, ukucwangciswa okusemgangathweni kunyanzelekile ukupholisa umoya wendalo);

17. Inkqubo yokubuyisela i-rosin: I-rosin ihamba ngendlela ehamba phambili, ekulungele kakhulu ukutshintshwa nokucoca.Imibhobho ekhethekileyo isetyenziselwa ukuhambisa igesi yokukhupha, engagcinwanga ubomi bonke;

18. Isakhiwo esikhethekileyo sothutho lomoya olucinezelekileyo kunye noyilo olukhethekileyo lwecingo lokufudumeza, akukho ngxolo, akukho ngcangcazelo, izinga lokutshintshiselana ngobushushu obuphezulu, umahluko weqondo lobushushu △t phakathi komzantsi weBGA kunye nebhodi yePCB incinci kakhulu, eyona idibanayo nengqongqo. Iimfuno zenkqubo yokukhokela, ngakumbi kwiimveliso ezingenalo ilothe ezinobunzima obuphezulu beemfuno zokuthambisa.

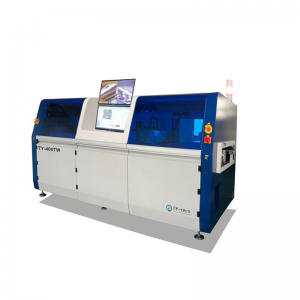

Umfanekiso weenkcukacha

Iinkcukacha

| Umzekelo | I-TYtech 6010 | |

| Inkqubo yokufudumeza | Inani leendawo zokufudumeza | PHEZULU 6/PHANTSI 6 |

| Inani leendawo zokupholisa | phezulu 1/PHANTSI 1 | |

| Ubude beendawo zokufudumeza | 2500MM | |

| Imo yokufudumeza | umoya oshushu | |

| Imo yokupholisa | Umoya ngamandla | |

| Inkqubo yoMhambisi | Max.Ububanzi bePCB | 300mm |

| Ububanzi bebhanti yomnatha | 400mm | |

| Umkhombandlela wothumelo | L→R(okanye R→L) | |

| Ugqithiso lwe-Net Height | 880±20mm | |

| Uhlobo logqithiso | Umnatha kunye nekhonkco | |

| Uluhlu lobubanzi bomzila | 0-300mm | |

| Isantya somhambisi | 0-1500mm/min | |

| Ubude becandelo | Phezulu 35mm, ezantsi 25mm | |

| Auto/manual Lubrication | umgangatho | |

| Indlela ye-hood ephezulu | Ihood yombane ezenzekelayo | |

| Umzila kaloliwe osisigxina | Uloliwe wangaphambili ulungisiwe(ukhetho: uloliwe ongasemva ulungisiwe) | |

| Amacandelo aphezulu | Phezulu nasezantsi 25mm | |

| Inkqubo yokulawula | Ukunikezwa Amandla | 5line 3phase 380V 50/60Hz |

| Amandla okuqalisa | 18kw | |

| Ukusetyenziswa kwamandla okuqhelekileyo | 4-7KW | |

| Ixesha lokufudumala | Malunga nemizuzu engama-20 | |

| Temp.uluhlu lokucwangcisa | Ubushushu begumbi-300℃ | |

| Temp.indlela yokulawula | I-PLC kunye nePC | |

| Temp.lawula ukuchaneka | ±1℃ | |

| Temp.ukutenxa kwiPCB | ±2℃ | |

| Ukugcinwa kwedatha | Inkqubo yeDatha kunye nokugcinwa kwesimo (80GB) | |

| Ipleyiti yomlomo | Icwecwe leAluminiyam yengxubevange | |

| I-Alarm engaqhelekanga | Ubushushu obungaqhelekanga.(iqondo lobushushu elongezelelweyo/eliphantsi kakhulu.) | |

| Ibhodi yawisa i-alam | Isibane seTower: Ukufudumala okutyheli, okuluhlaza-okuqhelekileyo, okubomvu-okungaqhelekanga | |

| Ngokubanzi | Ubungakanani(L*W*H) | 3600×1100×1490mm |

| Ubunzima | 900KG | |

| Umbala | Ikhompyuter engwevu | |

-

Umatshini wokuCoca iStencil soMbane TY-800

-

PCB Productionn Line SMT PCB Link Conveyor

-

UMirtec MV 6 OMNI 3D Inline AOI Umatshini wokuhlola

-

Iindawo ezi-6 zokuFudumeza Umoya oshushu we-Oveni ye-SMT yokuFuyela kwakhona kweLed...

-

Umatshini wokuHlola weStencil ozenzekelayo TY-SI80

-

I-SMT Intloko ephindwe kabini kwi-PCB eKhethekileyo yeWave Solde...