Feature

Function configuration:

2D Inspection

Glue amount detection: By detecting the size of the glue area, it can be judged whether there is too much glue, too little glue, missing spots or scattered spots at the gluing position.

Glue width and height detection: detect the width and thickness of the glue line, and judge whether the glue is compliant.

2D glue detection can effectively intercept various dispensing failures and improve the yield of shipments.

Wiping system: For the residue glue with high viscosity or not conducive to vacuum cleaning, the automatic wiping system simulates the action of human hand to effectively clean the residue glue on the nozzle.

Microbalance: monitor the spray single point glue weight, timely adjust the spray glue state, to ensure that the amount of product glue.

Flexibility: DLED Series intelligent fully digital dispensing platform can significantly reduce process errors, reduce operation difficulty, increase production and reduce costs. The closed-loop process control function provided by the software controllable temperature, colloid and gas pressre completely avoids manual adjustment by the operator. With its flexible and upgradeable features, the DLED series intelligent dispensing system can be upgraded to meet the dispensing needs of 1.5 meter long PCBs according to the user's product needs.

High value-added: GKG has rich experience in research and development, manufacturing, sales and service of precision,automation equipment industry, involving smart phones, automative electronics, medical machinery, LED and other fields. Rich technology and process precipitation provide usersvery highly reliable production techbology and sustainable technological innovation. From intial process development to fll production, users will always be supported by our worldwide engineering experience, application development and technical service network.

High Reliability: DLED software provides advanced yield, glue volume management and process control. DLED provides molti-layer operation control, while allowing operators to complete basic production operations, it also provdies engineers with a friendly user interface for program development. Use calibrated process jetting or flow control technology to ensre repeatable glye volume over long prodction runs, resulting in better dispensing accuracy and process performance.

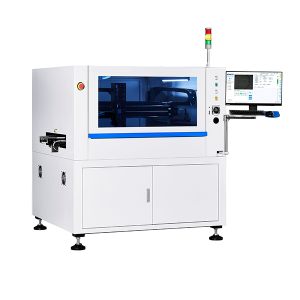

Detail Image

Specifications

| Model | DLED |

| PCB Max Size | 890*510mm |

| PCB Min Size | 50*60mm |

| PCB Thickness | 1~6mm |

| Transport Height | 900±40mm |

| Transport Direction | L-R/R-L |

| Product Weight | ≤3kg |

| Conveyor Edge Distance | ≥9mm |

| Bottom of Componet Height | ≤10mm |

| Lifter Method | Side lifter |

| Conveyor Stage | Two-stage transport rail |

| I/O Interface | SMEMA |

| Cleaning System | Vaccum cleaning glue |

| CCD FOV | 13*10mm |

| Vision | CCD |

| Position Accuracy | ±50µm@3sigma |

| Repeat Position Accuracy | ±25µm@3sigma |

| Operating System | Windows 7 |

| Air Supply | 4~6Kgf/cm2 |

| Power Supply | AC:220±10%, 50/60HZ 1.5KW |

| Control Method | PC control |

| Machine Dimension | 1600*1258*1490mm |

| Machine Weight | ~1000kg |