Isici

1. Uhlelo oluphelele lokuhlanza: hlanza kahle nangempumelelo izinto eziphilayo nezingaphili ezisele phezu komkhiqizo;

2. Imodi yokuhlanza ngokuzenzakalelayo ngokugcwele: qedela izinqubo zokuhlanza, ukuhlanza nokomisa ekamelweni elilodwa lokuhlanza, ngosayizi omncane kanye nesakhiwo esihlangene;

3. Idizayini yombhobho wesayensi kakhulu: ukusatshalaliswa okukhuphukayo kwesobunxele nakwesokudla kuyamukelwa ukuze kuthuthukiswe ukusebenza kahle kokuhlanza;ukusatshalaliswa kwe-dislocation ephezulu naphansi kuxazulula ngokuphelele indawo eyimpumputhe yokuhlanza;

4. Idizayini yengcindezi ye-nozzle eguquguqukayo: inciphisa ingozi efihliwe yokushayisana nokuchaphaza okubangelwa imikhiqizo enosayizi omncane ngaphansi kwezimo zokufutha ezinomfutho ophezulu ngesikhathi sokuhlanza;

5. Isistimu yokushisa ye-dilution evamile: ithuthukisa kakhulu ukusebenza kahle kokuhlanza futhi inciphise isikhathi sokuhlanza;

7. Usayizi omkhulu wokusebenza kwesikrini sokuthinta isikrini: usebenzisa isikrini sokuthinta umbala esizinzile nesithembekile, imingcele yenqubo yokuhlanza ehlukene ingasethwa ngokusho kwemikhiqizo ehlukene, futhi ukusebenza kulula;

8. Izinga eliphakeme lokuhlanzeka: izinga lokunukubezeka kwe-ionic lithobelana ngokugcwele nezinga le-Class III le-IPC-610D (ngaphansi kuka-1.56μg/cm², njengendinganiso) kanye nezinga le-Class I lezinga lezempi lase-US MIL28809;

9. Indlela yokulinganisa ye-ejenti yokuhlanza elula: ingafakwa ngesandla, noma ingaxuba ngokuzenzakalelayo amanzi e-DI kanye noketshezi lwamakhemikhali ngokwesilinganiso esibekiwe (5% -25%);

Uhlelo lokulawula ngogesi

①Ibhokisi likagesi elilawulayo eliyinhloko lilawulwa phakathi nendawo futhi libekwe endaweni yokusebenza komshini, elilungele ukulawula nokusebenza komshini.

②Umshini ulawulwa yi-Mitsubishi PLC nge-software ezenzakalelayo yesikrini sokuthinta, eyenza ukusebenza kube lula.

③Ukwaziswa kwe-alamu kanye nedizayini ye-buzzer iqinisekisa ukuthi abasebenzi bangakwazi ukuqonda ngokunembile isimo sokusebenza kwesisetshenziswa.Uma umshini ungavamile, i-buzzer izokhala futhi ilambu elibomvu lizokhanya.

④ Kunamathuluzi okuvikela iminyango ngaphambili nangaseceleni komshini ukuvimbela ingozi ebangelwa ukukhohlwa ukuvala umnyango ngenxa yezinto zomuntu.

⑤Ukulawulwa kwezinga lokushisa kusebenzisa i-PID ezenzakalelayo kanye ne-analog control algorithm, engalawula ngokuqinile ukuchezuka kwezinga lokushisa, futhi ukukhuphuka nokuwa kwezinga lokushisa kuzinze kakhudlwana.

⑥Ngaphezu kwedivayisi yokulawula izinga lokushisa okuzenzakalelayo, ingxenye yokushisisa ifakwe umsebenzi wokuvikela izinga lokushisa elingaphezu kokushisa ukuze kuvinjelwe umonakalo emshinini uma kwenzeka kuba nezingozi.

⑦Injini ngayinye yomshini ifakwe umsebenzi wokuvikela ukugcwala ngokweqile, okungavimbela ngempumelelo ukulimala kwemishini ngaphansi kwezimo ezingavamile.

⑧ Uma iphutha lenzeka, umshini uzokhipha i-alamu, futhi imininingwane yephutha izovezwa embhalweni esikrinini sekhompyutha ngesikhathi esifanayo, ukuze kufike ngesikhathi.

Funda mayelana nokuxazulula inkinga.

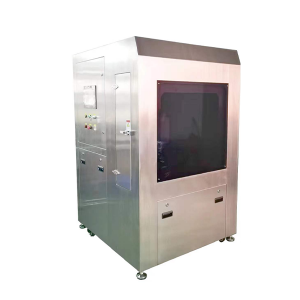

Imininingwane yesithombe

Ukuhlanza Into

Ibhodi Elingaphrintiwe

PCBA

Imininingwane

| Imodeli | I-TY-560 |

| UkuhlanzaLumen size | L690*W620*H715(mm) |

| Hlanza Usayizi Webhasikidi | L610*W560*H100(mm) idizayini yesendlalelo esikabili |

| Ubukhulu bomshini | L1200*W1100*H 1780±30(mm) |

| Isisindo Somshini | 400KG |

| Gxila Umthamo Wamathangi | 30L |

| I-Diluent Tank Umthamo | 70L |

| Isikhathi Esiqinile Esihlanzekile | 3~8 amaminithi (inkomba) |

| Isikhathi Sokomisa | 20 ~ 30 imizuzu (inkomba) |

| Amandla Esinxephezelo Sezinga Lokushisa Kwe-Cavity | 6KW |

| I-Solvent Tank Heater Amandla | 9KW |

| Amandla Wephampu Yesifutho Evundlile | 5.5KW |

| Ukubuyiselwa Kwe-Chemical Liquid Nokuhlunga | 5μm (hlunga izinhlayiya ezincane zokungcola okufana ne-solder paste, rosin, flux, njll.) |

| Umthombo Wegesi | 0.45-0.7Mpa |

| Ukunikezwa kwamandla kagesi | I-AC380V 3P, 50/60HZ 27KW |

| Isistimu yokufafaza | Ukuhlanza isifutho esiphendukayo esingu-360-degree phezulu naphansi |

| I-Exhaust Port Size | Φ100mm(W)*30mm(H) |

| Ukuhlanza i-Jet Pressure Range | 0.3~0.6(Mpa) |

| Spray Tank Umthamo | 17L-23L |

| Hlanza Umthwalo Webhasikidi | 100KG |

| Hlanza Isikhathi | Imizuzu eyi-1 ~ 2/isikhathi, izikhathi ezi-1-10 (setha njengoba kudingeka) |

| Liquid Heating Temperature | 〜75P |

| I-Hot Air Drying Temperature Temperature Yegumbi | 〜99P |

| Ukomisa Amandla We-heater | 6KW |

| Ibanga Lokuqapha Lemitha Yokumelana | 0~ 18MQ•cm |

| I-DI Water Discharge Filtration | 5μm ukuhlunga izinhlayiya ezincane zokungcola okufana ne-solder paste, i-rosin, i-flux, njll.) |

| I-Inlet kanye ne-Outlet | 1 intshi yokuxhumana okusheshayo |

| I-3-Stage Filtration System | Isihlungi sesiteji sokuqala (isihlungi sokungcola namalebula) Isihlungi sesiteji sesibili (hlunga izinhlayiya ezincane nokunamathisela kwe-solder) Isihlungi sesiteji sesi-3 esingu-5um (hlunga izinhlayiya ezincane nerosin) |

| Inani lokuhlanza | Ibalwa ngebhodi le-PCBA elinosayizi L200×W100×H20(mm), iqoqo ngalinye lingageza 100-160pcs |

Ukuqhathaniswa komphumela wokuhlanza

Ngaphambili

Ngemva

-

Umshini Wokuhlanza Wezitezi Zomoya Ogcwele TY-PS750

-

Umshini Wokuhlanza Izitezi zikagesi TY-800

-

Umshini Wokuhlanza Umshini Kagesi Wokufutha Istencil We-SMT...

-

Umshini Wokuhlanza I-Pneumatic Stencil TY-750

-

Umshini Wokuhlanza Amaphalethi E-Solder TY-C800

-

I-PCBA Cleaning Machine Ye-SMT Machine Line PCB ...