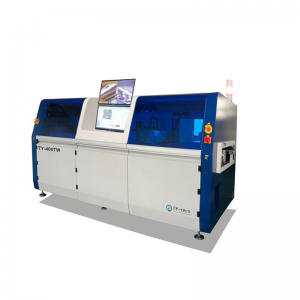

Ihovini Yamahhala Yokugeleza Komoya Oshisayo TY-1220

Isingeniso:

1. Ikhompyutha yomkhiqizo kanye nesistimu yokulawula ehlakaniphile ye-Siemens PLC, ukulawulwa kwezinga lokushisa okunembayo okuphezulu ngu-± 1-2 ℃ (uma ingozi yokuphahlazeka kwekhompyutha, ingakwazi ukubona umsebenzi ongekho ku-inthanethi, ingathinti ukukhiqizwa) kanye nokuqinisekisa ukuthi uhlelo lokulawula lukhona. ezinzile futhi enokwethenjelwa;

2. Isixhumi esibonakalayo seWindows XP esisebenza ngamandla futhi kulula.

I-3.Ukuze uqinisekise ukuphepha nokuthembeka, umzimba we-cylinder ungaphakanyiswa ngokuzenzakalelayo.

4. Idivayisi ifakwe ibhande le-mesh, ithuthwa kahle, akukho ukuzamazama futhi akukho kuguqulwa, okuqinisekisa ukuthuthwa kwe-PCB okubushelelezi.I-synchronous guide transmit mechanism kanye nokuxhumeka kwe-inthanethi komshini we-SMT okuzenzakalelayo kuqinisekisa ukuthi umhlahlandlela oguquguqukayo onembile nempilo yesevisi ephezulu.

5. Isistimu yokugcoba yokulawula okuzenzakalelayo kanye neketango lokudlulisa ukugcoba okuzenzakalelayo.

6.Konke ukulawulwa kwendawo yokushisa nge-PID yekhompyutha(indawo yokushisa ephezulu kanye nokuqaliswa kokulawula okuzimele kwendawo yokushisa, lokho kusho ukuthi kungahlukanisa ukushisa kwendawo, ukuze kuncishiswe amandla okuqala)

7. Ukudluliswa kwe-net/chain ngekhompyutha ukuze kwenziwe isilawuli se-loop esivaliwe, esingahlangabezana nezinhlobo ezahlukene zokukhiqizwa kwe-PCB ngesikhathi esisodwa.

8. Ngomsindo wephutha nomsebenzi we-alamu okhanyayo.

9. Ngomvikeli wokuvuza, qinisekisa ukuthi abasebenzi abasebenzayo kanye nokuphepha kwesistimu yokulawula.

10.I-UPS eyakhelwe ngaphakathi kanye nohlelo lokulibaziseka oluzenzakalelayo lwesiqinisekiso sokubuyisela isishiseli ngamandla noma ukushisa ngokweqile akulimazi i-PCB nomshini.

11. I-ERSA yaseJalimane ehamba phambili emhlabeni imodi yokushisa ye-microcirculation, kanye nesistimu ye-microcirculation yomoya ephezulu nephansi, ukufana kwezinga lokushisa kanye nesinxephezelo esishisayo, ukusebenza kahle okuphezulu kwe-supercharged accelerated air duct, kuthuthukisa kakhulu ukugeleza komoya oshisayo ojikelezayo, ukushisa ukushisa ngokushesha (mayelana imizuzu engamashumi amabili), isinxephezelo esishisayo sokusebenza kahle okuphezulu, izinga lokushisa eliphakeme lokushisela nokuphulukisa;

12. Engaphezulu naphansi kwayo yonke indawo yokushisa enenzwa ezimele engenisa izinga lokushisa, ukuqapha kwesikhathi sangempela kanye nesinxephezelo kuyo yonke ibhalansi yendawo yokushisa;

13. Yiba nokuphathwa kwephasiwedi yesistimu yokusebenza, ukuvimbela izinguquko ezingabalulekile zabasebenzi emingceleni yenqubo, amarekhodi okusebenza okuphathwa kwenqubo yokulandela ukulandela imingcele inqubo yokushintsha, ukuthuthukisa ukuphathwa okulula.Okokugcina izilungiselelo zejubane lokushisa elikhona lomsebenzisi kanye nezilungiselelo zejika lokushisa, futhi zingasetshenziselwa yonke idatha nokuphrinta kwekhevu;

14. Iwindi lokulawula elididiyelwe, inkinobho yekhompyutha, ijika lokuhlola, ijika lokuphrinta kanye nokudluliswa kwedatha kusebenza kalula, umklamo owenziwe umuntu.Ifakwe uhlelo lwe-inthanethi lokuhlola izinga lokushisa kwejika lejika leziteshi ezintathu, nganoma yisiphi isikhathi ingahlola izinto zokushisela ngejika langempela lokushisa (ngaphandle kwesinye isihloli sejika lokushisa lokufanisa);

15. Kusukela ohlelweni lokupholisa okusheshayo lobuchwepheshe bamazwe ngamazwe, sebenzisa uhlobo lwengilazi yokukhulisa ephumelelayo ukupholisa okusheshayo, isivinini sokupholisa singafinyelela ku-3.5 ~ 6 ℃/ SEC, ukuphathwa kulula kakhulu;Idivayisi yokupholisa ephoqelelwe yangaphandle, iqinisekisa ukuthi umphumela wekristalu yendawo (Izinto ezikhethiwe ezikhethiwe, ukumiswa okujwayelekile kokupholisa komoya wemvelo okuphoqelelwe).

Ukucaciswa:

| Imodeli | I-TY-Tech 1220 | ||

| Isistimu Yokushisa | Inombolo yezindawo zokushisisa | Phezulu 12/ phansi 12 | |

| Inombolo yezindawo zokupholisa | 2 | ||

| Ubude bezindawo zokushisisa | 4640 mm | ||

| Imodi yokushisa | Umoya oshisayo | ||

| Imodi Yokupholisa | Ukupholisa umoya ngempoqo | ||

| I-Exhaust Volume | 10m³/min * 2 exhauss | ||

| I-Conveyor System | Ubukhulu.Ububanzi be-PCB | 400mm | |

| Ububanzi bebhande lemeshi | 450mm | ||

| Transmission Direction | L→R(inketho: R→L) | ||

| Ukuphakama KweNet | 900±20mm | ||

| Uhlobo lokudlulisela | I-Mesh neketanga | ||

| Ibanga lobubanzi besitimela | 400mm | ||

| Isivinini se-Conveyor | 0-2000mm/min | ||

| Auto/manual Lubrication | Okujwayelekile | ||

| Uhlangothi lwesitimela olungaguquki | Isitimela sangaphambili silungisiwe(inketho: isitimela sangemuva silungisiwe) | ||

| Izingxenye ziphezulu | Phezulu nangaphansi 25mm | ||

| Isistimu yokulawula | Ukunikezwa kwamandla kagesi | 5 umugqa 3 isigaba 380V 50/60HZ | |

| Amandla aphelele | 48KW | ||

| Ukusetshenziswa kwamandla okuvamile | 10-12KW | ||

| Isikhathi sokufudumala | 20 imiz | ||

| Temp.ibanga lokusetha | Kusukela ezingeni lokushisa legumbi.Kufika ku-300 ℃ | ||

| Temp.indlela yokulawula | I-PID vala i-loop control nokushayela kwe-SSR | ||

| Temp.lawula ukunemba | ±1℃ | ||

| Temp.ukuchezuka ku-PCB | ±2℃ | ||

| Ukugcinwa kwedatha | Cubungula idatha nesimo sokugcina(80GB) | ||

| Ipuleti le-nozzle | I-Aluminium Alloy Plate | ||

| I-alamu engavamile | Izinga lokushisa elingavamile (izinga lokushisa elingaphezulu-phezulu/eliphansi kakhulu) | ||

| Ibhodi lehlise i-alamu | Tower light:Ukufudumala okuphuzi, Okuluhlaza-okuvamile, Okubomvu-okungavamile | ||

| Okujwayelekile | Ubukhulu(L*W*H) | 6300*1320*1490mm | |

| Isisindo | 2600kg | ||

| Umbala | Ikhompyutha empunga | ||

Amagama angukhiye:Ihhavini ye-SMT Reflow, Ihhavini Yokugeleza Kwamahhala Eholayo, Ihhavini Yokugeleza Kakhulu, Ihhavini Lokushibilika Kabusha, I-Reflow Oven Manufacture, I-Led Reflow Oven, I-PCB Reflow Oven, I-Nitrogen Reflow Oven, I-Dual Lane Reflow Oven, I-China Reflow Oven, Umshini Wokusolisa we-PCB

I-FAQ:

Q. Iyini imfuneko yakho ye-MOQ yomshini?

A. 1 setha imfuneko ye-moq yomshini.

Q. Okokuqala ngisebenzisa lolu hlobo lomshini, ingabe kulula ukusebenza?

A: Kukhona imanuwali yesiNgisi noma ividiyo eqondisayo ekukhombisa ukuthi usetshenziswa kanjani umshini.

Umbuzo: Uma umshini uba nenkinga ngemva kokuwuthola, singakwenza kanjani?

A: Unjiniyela wethu uzosiza ukuyixazulula kuqala, futhi izingxenye zamahhala zikuthumela ngesikhathi sewaranti yomshini.

Q: Ingabe unikeza iwaranti yomshini?

A: Yebo iwaranti yonyaka ongu-1 izonikezwa umshini.

Q: Ngingalenza kanjani i-oda nawe?

IMP: Ungasifinyelela nge-imeyili, i-whatsapp, i-wechat futhi uqinisekise inani lokugcina, indlela yokuthumela kanye nesikhathi sokukhokha, sizobe sesikuthumelela i-invoyisi ye-proforma nemininingwane yethu yasebhange kuwe.