Ukuze uhlanganise ngempumelelo izingxenye ze-solder surface ebhodini lesekethe, ukushisa kufanele kudluliselwe ku-solder alloy paste kuze kube yilapho izinga lokushisa layo lifinyelela endaweni encibilikisiwe (217°C ku-SAC305 lead free solder).Ingxubevange ye-liquid izohlangana namaphedi ethusi e-PCB futhi ibe ingxube ye-eutectic alloy.Ijoyinti le-solder eliqinile lizokwakhiwa ngemva kokuba liphole ngaphansi kwephuzu elincibilikisiwe.

Kunezindlela ezintathu zokudlulisa ukushisa kusuka emthonjeni wokushisa kuya ezintweni ezishisayo.

- I-Conduction: I-Thermal conduction idlulisela ngokuqondile ngento lapho kunomehluko wamazinga okushisa phakathi kwezifunda ezixhumene, ngaphandle komnyakazo wento.Kwenzeka lapho izinto ezimbili emazingeni okushisa ahlukene zithintana.Ukushisa kugeleza kusuka kokufudumala kuya entweni epholile kuze kube kokubili kusezingeni lokushisa elifanayo.

- Imisebe: Ukudluliswa kokushisa ngemisebe kwenzeka ngendlela yamaza kagesi ikakhulukazi endaweni ye-infrared.Imisebe iyindlela yokudlulisa ukushisa engancikile kunoma yikuphi ukuxhumana phakathi komthombo wokushisa nento eshisayo.Umkhawulo wemisebe ukuthi umzimba omnyama uzomunca ukushisa okukhulu kunomzimba omhlophe.

- I-Convection: I-Heat Convection ukudluliselwa kokushisa kusuka endaweni eyodwa kuya kwenye ngokuhamba koketshezi olufana nomoya noma igesi yomhwamuko.Futhi kuyindlela yokungathinteki yokudlulisa ukushisa futhi.

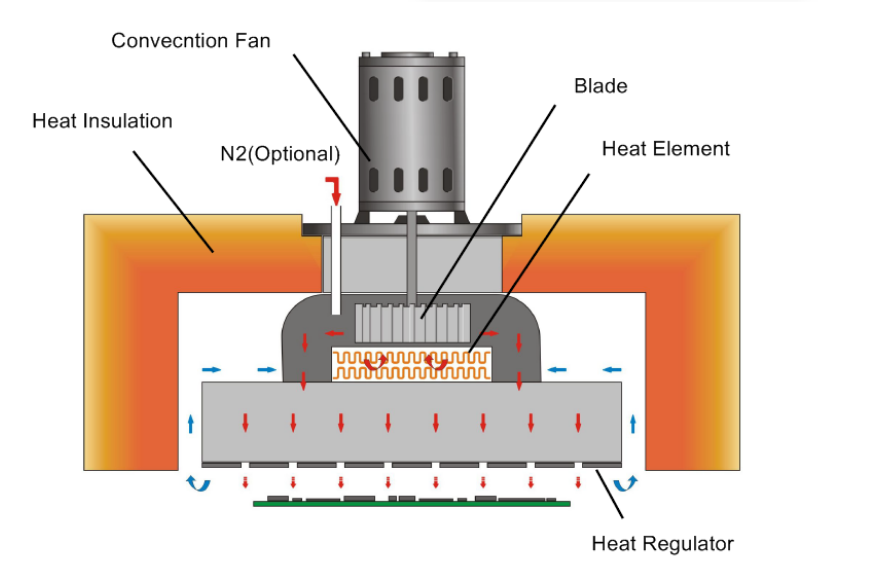

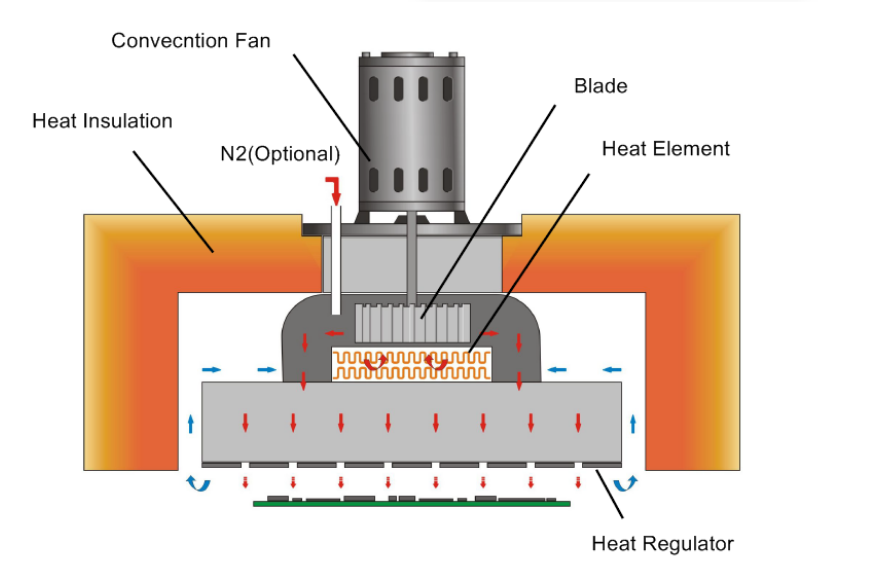

I-solder yesimanjereflow ovensebenzisa imiqondo yemisebe kanye ne-convection kuhlangene.Ukushisa kukhishwa isici sokushisa se-ceramic esinemisebe ye-infrared, kodwa akukulethi ku-PCB ngokuqondile.Ukushisa kuzodlulisela kusilawuli sokushisa kuqala ukuze kukhishwe ukushisa okulinganayo.I-fan ye-convection izovuthela umoya oshisayo ekamelweni elingaphakathi.I-PCB eqondiwe ingathola ukuvumelana kokushisa kunoma iyiphi indawo.

Isikhathi sokuthumela: Jul-07-2022