I-Reflow soldering iyindlela esetshenziswa kakhulu yokunamathisela izingxenye ze-surface mount kumabhodi wesekethe aphrintiwe (ama-PCB).Inhloso yale nqubo ukwakha amajoyinti amukelekayo e-solder ngokuqala ukushisa kuqala izingxenye / PCB/solder unama bese uncibilikisa i-solder ngaphandle kokudala umonakalo ngokushisa ngokweqile.

Izici ezibalulekile eziholela enqubweni esebenzayo yokuphinda i-reflow soldering yilezi ezilandelayo:

- Umshini ofanelekayo

- Iphrofayela eyamukelekile yokugeleza kabusha

- I-PCB/ingxenye ye-footprint Design

- I-PCB ephrintiwe ngokucophelela kusetshenziswa i-stencil eklanywe kahle

- Ukubekwa okuphindaphindiwe kwezingxenye zokukhweza ngaphezulu

- Ikhwalithi enhle ye-PCB, izingxenye kanye nokunamathisela kwe-solder

Umshini Ofanelekayo

Kunezinhlobo ezehlukene zomshini wokuphinda ugaywe we-solder otholakalayo kuye ngesivinini somugqa odingekayo kanye nomklamo/impahla yemihlangano ye-PCB ezocutshungulwa.Uhhavini okhethiwe udinga ukuba nosayizi ofanele ukuphatha izinga lokukhiqiza lempahla yokukhetha nendawo.

Isivinini somugqa singabalwa njengoba kukhonjisiwe ngezansi:-

Isivinini somugqa (ubuncane) =Amabhodi ngomzuzu x Ubude bebhodi ngalinye

Layisha Factor (isikhala phakathi kwamabhodi)

Kubalulekile ukucabangela ukuphindaphinda kwenqubo futhi ngakho 'Isici Somthwalo' ngokuvamile sicaciswa umkhiqizi womshini, isibalo esiboniswe ngezansi:

Ukuze ukwazi ukukhetha usayizi olungile wokugeleza kwehhavini isivinini senqubo (echazwe ngezansi) kufanele sibe sikhulu kunejubane elincane elibaliwe lomugqa.

Isivinini senqubo =Igumbi likahhavini ubude obushisiwe

Isikhathi sokuhlala senqubo

Ngezansi isibonelo sokubala ukuthola usayizi wehhavini olungile:-

Umhlanganisi we-SMT ufuna ukukhiqiza amabhodi angu-8-intshi ngenani elingu-180 ngehora.Umkhiqizi wokunamathisela we-solder uncoma imizuzu emi-4, iphrofayili yezinyathelo ezintathu.Ngidinga uhhavini isikhathi esingakanani ukuze ngicubungule amabhodi kulokhu kuphuma?

Amabhodi ngomzuzu = 3 (180/ihora)

Ubude bebhodi ngalinye = 8 amayintshi

Isici Somthwalo = 0.8 (isikhala esingu-2-intshi phakathi kwamabhodi)

Isikhathi Sokuhlala Kwenqubo = imizuzu emi-4

Bala isivinini somugqa:(3 amabhodi/min) x (8 amayintshi/ibhodi)

0.8

Isivinini somugqa = 30 amayintshi/ngomzuzu

Ngakho-ke, i-ovini yokugeleza kabusha kufanele ibe nesivinini senqubo okungenani amasentimitha angama-30 ngomzuzu.

Nquma ubude obushisiwe begumbi likahhavini ngesibalo sesivinini senqubo:

30 in/min =Igumbi likahhavini ubude obushisiwe

4 amaminithi

Ubude obushisiwe be-oven = 120 amayintshi (10 amafidi)

Qaphela ukuthi ubude behhavini buzodlula amafidi angu-10 kuhlanganise nesigaba sokupholisa kanye nezingxenye zokulayisha zokuthutha.Isibalo esobude be-HEATED - HHAYI UBUDE BUKAHHOVISI BONKE.

1. Uhlobo lwe-Conveyor - Kungenzeka ukukhetha umshini onemesh conveyor kodwa ngokuvamile ama-edge conveyor acacisiwe ukuze ihhavini lisebenze emgqeni futhi likwazi ukucubungula izingxenye ezihlangene ezizinhlangothini ezimbili.Ngokungeziwe kusihambisi sonqenqema ukusekela kwebhodi eliphakathi kuvame ukufakwa ukuze kumiswe i-PCB ekuwohlokeni ngesikhathi senqubo yokugeleza kabusha - bona ngezansi.Lapho ucubungula imihlangano ezinhlangothi ezimbili kusetshenziswa ukunakekelwa kwesistimu yokuhambisa unqenqema kufanele kuthathwe ukuze kungaphazamisi izingxenye ezingaphansi.

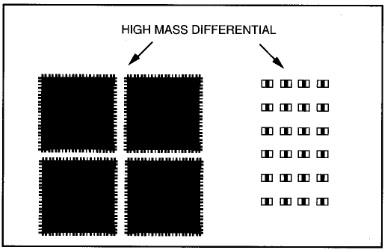

2. Ukulawulwa kwe-loop evaliwe yejubane labalandeli be-convection - Kunamaphakheji athile okufakwa phezulu okungaphezulu njenge-SOD323 (bheka ukufaka) anendawo encane yokuxhumana nesilinganiso sobuningi okungenzeka ukuthi siphazamiseke ngesikhathi senqubo yokugeleza kabusha.Ukulawulwa kwesivinini se-loop esivaliwe sabalandeli bomhlangano kuyindlela enconyiwe yemihlangano esebenzisa izingxenye ezinjalo.

3. Ukulawula okuzenzakalelayo kwe-conveyor kanye nobubanzi bokusekelwa kwebhodi eliphakathi - Eminye imishini inokulungiswa kobubanzi okwenziwa ngesandla kodwa uma kukhona amaqoqo amaningi ahlukene okufanele acutshungulwe ngobubanzi obuhlukahlukene be-PCB khona-ke le nketho iyanconywa ukugcina inqubo engashintshi.

Iphrofayela Yokugeleza Kabusha eyamukelekile

- Uhlobo lokunamathisela kwe-solder

- PCB impahla

- Ubukhulu be-PCB

- Inombolo yezendlalelo

- Inani lethusi ngaphakathi kwe-PCB

- Inombolo yezingxenye zokukhweza ngaphezulu

- Uhlobo lwezingxenye zokukhweza ngaphezulu

Ukuze udale iphrofayela egeleza kabusha ama-thermocouples axhunywe kumhlangano wesampula (ngokuvamile nge-solder yokushisa okuphezulu) ezindaweni eziningi ukuze kulinganiswe ububanzi bamazinga okushisa ku-PCB yonkana.Kunconywa ukuthi okungenani kube ne-thermocouple eyodwa ebekwe phezu kwephedi ngasemaphethelweni e-PCB kanye ne-thermocouple eyodwa ebekwe phezu kwephedi maphakathi ne-PCB.Ngokufanelekile ama-thermocouples engeziwe kufanele asetshenziselwe ukukala ububanzi obugcwele bamazinga okushisa kuyo yonke i-PCB - eyaziwa ngokuthi 'i-Delta T'.

Ngaphakathi kwephrofayili ye-reflow soldering evamile ngokuvamile kunezigaba ezine - Ukushisa, ukucwilisa, ukugeleza kabusha nokupholisa.Inhloso eyinhloko ukudlulisa ukushisa okwanele emhlanganweni ukuze kuncibilike i-solder futhi yakhe amalunga e-solder ngaphandle kokudala umonakalo ezingxenyeni noma kwi-PCB.

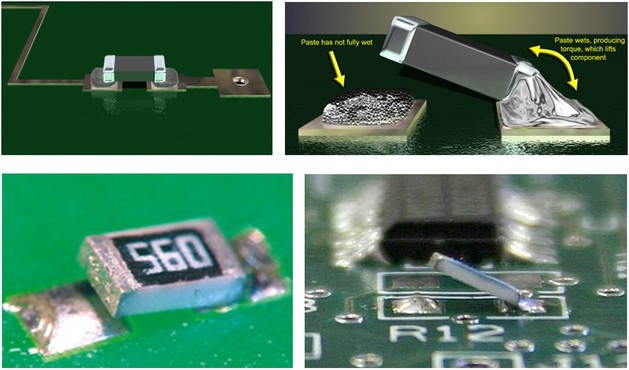

Shisisa ngaphambili– Phakathi nalesi sigaba izingxenye, i-PCB kanye ne-solder konke kushisiswe endaweni ethile noma kumazinga okushisa okuhlala ngokuqaphela ukuthi angashisi ngokushesha (imvamisa angabi ngaphezu kuka-2ºC/sesekhondi – hlola imininingwane yedatha ye-solder).Ukushisa ngokushesha kungabangela ukukhubazeka okufana nezingxenye ukuthi ziqhekeke futhi i-solder inamathisele i-splatter ibangele amabhola e-solder ngesikhathi sokugeleza kabusha.

Cwilisa- Inhloso yalesi sigaba ukuqinisekisa ukuthi zonke izingxenye zifinyelela ezingeni lokushisa elidingekayo ngaphambi kokungena esigabeni sokugeleza kabusha.I-Soak ngokuvamile ihlala phakathi kwamasekhondi angu-60 kanye ne-120 kuye ngokuthi 'umehluko omkhulu' wenhlangano kanye nezinhlobo zezingxenye ezikhona.Uma ukudlulisa ukushisa kuphumelela kakhulu phakathi nesigaba sokucwilisa kudingeka isikhathi esincane.

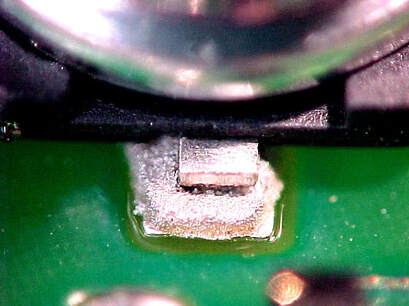

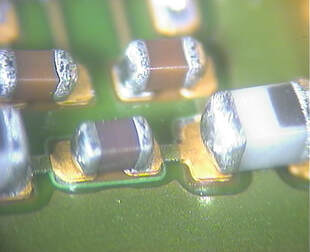

Isici esivamile sokudambisa ngemva kokugeleza kabusha ukwakheka kwamabhola/ubuhlalu obuphakathi kwe-chip njengoba kungabonakala ngezansi.Isixazululo salesi sici ukuguqula ukwakheka kwe-stencil -eminye imininingwane ingabonwa lapha.

Ukupholisa- Lesi yisiteji lapho ukuhlanganisa kupholiswa khona kodwa kubalulekile ukuthi ungapholisi ukuhlanganiswa ngokushesha okukhulu - ngokuvamile izinga lokupholisa elinconywayo akufanele lidlule ku-3ºC/ngesekhondi.

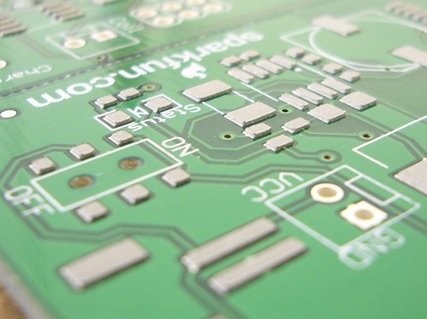

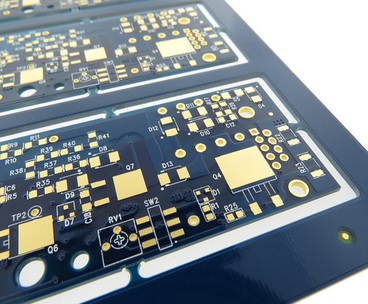

PCB/Component Footprint Design

I-PCB ephrintiwe ngokucophelela kusetshenziswa i-stencil eklanywe kahle

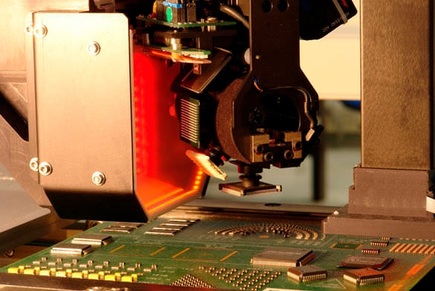

Ukubekwa okuphindaphindiwe kwezingxenye zokukhweza ngaphezulu

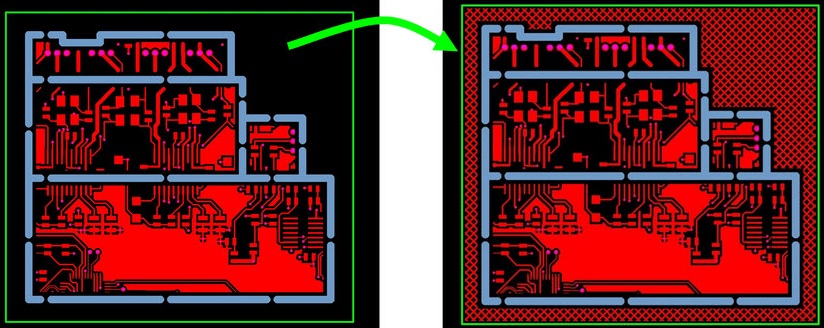

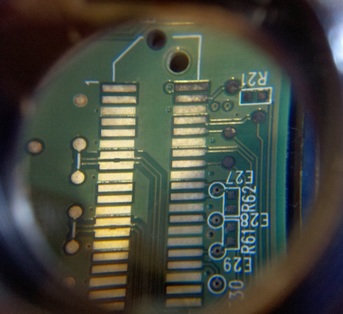

Izinhlelo zokubeka izingxenye zingadalwa kusetshenziswa imishini yokukhetha nendawo kodwa le nqubo ayinembile njengokuthatha ulwazi lwe-centroid ngokuqondile kudatha ye-PCB Gerber.Imvamisa le datha ye-centroid ithunyelwa isuka ku-PCB design software kodwa ngesinye isikhathi ayitholakali ngakho-keservice ukukhiqiza ifayela centroid kusuka idatha Gerber inikezwa Surface Mount Process.

Yonke imishini yokubeka izingxenye izoba 'nokunemba kokubekwa' okucaciswe njengokuthi:-

35um (QFPs) kuya ku-60um (ama-chips) @ 3 sigma

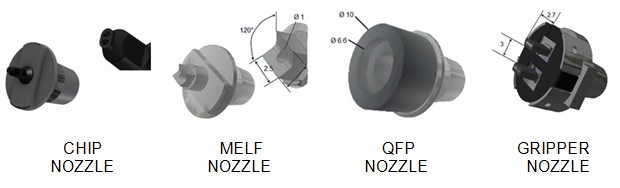

Kubalulekile futhi ukuthi kukhethwe umlomo wombhobho ofanele ohlotsheni lwengxenye ezobekwa - uhla lwezimbobo zokubeka izingxenye ezahlukene lungabonakala ngezansi:-

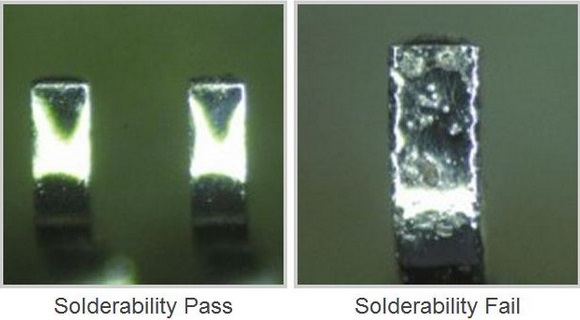

Ikhwalithi enhle ye-PCB, izingxenye kanye nokunamathisela kwe-solder

Isikhathi sokuthumela: Jun-14-2022