Isici

Izici:

1. Ukusebenzisa isithando somlilo sethayina sephampu ye-electromagnetic, igagasi lethini liphezulu, ukugeleza kukhulu, ukuphakama kwegagasi kuzinzile, ukujula kokungena kwe-solder kukhulu, futhi amandla okumanzisa nawokunamathisela anamandla.

2. I-periphery ye-nozzle kanye nengaphezulu le-solder zivikelwe ukugcwaliswa kwe-nitrogen, okungathuthukisa ukuthengiswa kwe-solder-free solder, ukunciphisa inani le-tin slag ekhiqizwa, ukuvimbela umlomo wombhobho ukuthi ungavali, futhi konga izindleko zokushisela nokusebenza. izindleko.

3. Ukumelana nokushisa okuphezulu, ukumelana nokugqwala kanye ne-nozzle eyingqayizivele, ukumelana ne-oxidation eqinile, ukumanzisa okuhle, isikhathi sokusebenzisa esivamile singafinyelela ezinyangeni ezi-3.

4. Thola ngokuzenzakalelayo izinga le-solder liquid ukuze uqinisekise iziqongo zamagagasi ezinzile.

5. Ine-solder joint slimming function.

6. Iza ejwayelekile namakhamera amabili e-CCD ukuqapha isimo sokushisela kanye nezinhlelo zokuma kwe-PCB.

Uhlolojikelele lwezinzuzo zohlelo:

n Konke emshinini owodwa, ikaniukuhlalisa3 amabhodi noma3 i-pallet, enye i-spray flux, enye ishisa ngaphambili, enye i-soldering, ithola isivuno esikhulu sokukhiqiza.

n Ithebula le-spray flux ngayinye kanye netafula lokunamathisela.

n Izinga eliphezulu lokudambisa.

n Ukuxhumana kwe-SMEMA kunamandla.

n Ukulawula okugcwele kwe-PC.Yonke imingcele ingasethwa ku-PC futhi igcinwe kumenyu ye-PCB, njengendlela ehambayo, izinga lokushisa le-solder, uhlobo lwe-flux, uhlobo lwe-solder,N2izinga lokushisa njll., ikhono elingcono kakhulu lokulandelela kanye nekhwalithi yokuphinda iphinde ifakwe kalula.

Ingxenye1: Isofthiwe

- Lonke uhlelo lwe-software oluthuthukiswe inkampani evela e-USA, enolwazi lwethu lweminyaka engu-8 mayelana nokudayiswa okukhethekile, okusekelwe ohlelweni lwe-Windows7, olunekhono elihle lokulandela umkhondo.

- Sebenzisa isithombe esiskeniwe njengesizinda sohlelo lwendlela, isivinini esinyakazayo, isikhathi sokuhlala, isivinini sokunyakaza esingenalutho, ubude buka-Z, ukuphakama kwegagasi njll konke okuhlelelwe isayithi elihlukile lokuthengisa.

- Bonisa inqubo ye-solder ngekhamera ebukhoma.

- Amapharamitha abalulekile angaphansi kokuqashwa ngokuphelele yisoftware ye-PC, njengezinga lokushisa, isivinini, ingcindezi njll.

- Ingathuthukiswa ukuze ibe nomsebenzi wokulinganisa ukuphakama kwegagasi lokuzenzakalelayo, ukuhlola nokulinganisa igagasi's ukuphakama ngemva kwe-pcb ngayinye ethile, ukuze ugcine ukuzinza okuhle kakhulu kwamagagasi.

- Mayelana ne-PCB's imenyu emshinini wokunamathisela, lonke ulwazi luzofakwa efayeleni elilodwa.Kuzobandakanya ubukhulu be-PCB nesithombe, uhlobo lwe-flux esetshenzisiwe, uhlobo lwe-solder, uhlobo lwe-solder nozzle, izinga lokushisa le-solder, izinga lokushisa le-N2, indlela yokunyakaza kanye nesayithi ngalinye.'s ahlobene ukuphakama kwegagasi nobude Z njll. Lapho ikhasimende solder PCB efanayo, bangathola ulwazi olugcwele mayelana kanjani's kwenziwa emlandweni, futhi kulula ukulandelela.

Ingxenye2: isistimu yokunyakaza

- Ithebula elinyakazayo lokuziklama eline-aluminium ekhonjiwe, isisindo esilula nesivinini sokunyakaza esisheshayo.

-

I-Panasonic servo motor & driver ihlinzeka ngamandla okushayela azinzile, ngesigxobo sesikulufa & nomzila wesitimela wenhlangano ukuze uthole isiqondiso.Isikhundla esiyigugu, umsindo omncane, ukunyakaza okuzinzile.

- Ngepuleti elivikela uthuli ngenhla kwetafula elinyakazayo, ukuze ugweme ukuguquguquka noma ukwehla kwe-solder ukulimaza isikulufu sebhola.

Ingxenye 3: Isistimu yokuguquguquka

- Okujwayelekile kufakwe i-valve yejethi engenisiwe ukuze uthole umphumela oguquguqukayo oyigugu onechashaza elincane eligelezayo, sicela uqaphele okuqukethwe okuqinile kwe-flux kufanele kube ngaphansi kuka-10%.

- I-Flux ifakwe ithangi lokucindezela lepulasitiki le-PP, qiniseka ukuthi ingcindezi izinzile ngaphandle kokuthonywa inani lokuguquguquka.

Ingxenye 4: Preheat

- Phezulu kwe-conveyor ne-bottm ifakwe ukushisisa kwangaphambili kwe-IR.Isikhundla siyalungiseka.

- Isilinganiso sokushisa sishintshwa yi-PC, ukusuka ku-0 ---100%

Ingxenye 5: ibhodwe elikabili

- OKUBILIuhlelo lwebhodwe le-solder elinokulawula ukushisa komuntu ngamunye, ukulawulwa kwezinga lokushisa kwe-N2, ukulawula ukuphakama kwamagagasi.Konke kufakwe etafuleni elilodwa.Ibanga phakathi kwebhodwe le-solder lingashintshwa.

- Izinga lokushisa le-solder, izinga lokushisa le-N2, ukuphakama kwegagasi, ukulinganiswa kwamagagasi njll konke okukwazi ukusetha isofthiwe.

- Ibhodwe le-solder lenziwe nge-Ti, hhayi ukuvuza.Ine-heater yensimbi ngaphandle, ishisa futhi ishisa ngokushesha.

- Ibhodwe le-solder lifakwe intambo ngesixhumi esisheshayo.Uma ushintsha ibhodwe le-solder ngaphandle kokuhlanganisa kabusha izintambo ezidingekayo, vele uxhume futhi udlale.

- Isistimu yokushisisa ye-inthanethi ye-N2, ukumanzisa i-solder kahle futhi yehlise amanyela e-solder.

- Ngokuhlola izinga le-solder ne-alamu.

Ingxenye 6: umthumeli

- I-Stepper motor drive yesihambisi esingaguquki nesihambayo.

- Ngerola yensimbi engagqwali ye-conveyor, engagqoki nokusetshenziswa isikhathi eside.Futhi qiniseka ukuthi i-solder nozzle ingasondela ebhodini'unqenqema 3mm.

- Nge-PCB clamping system at conveyor.

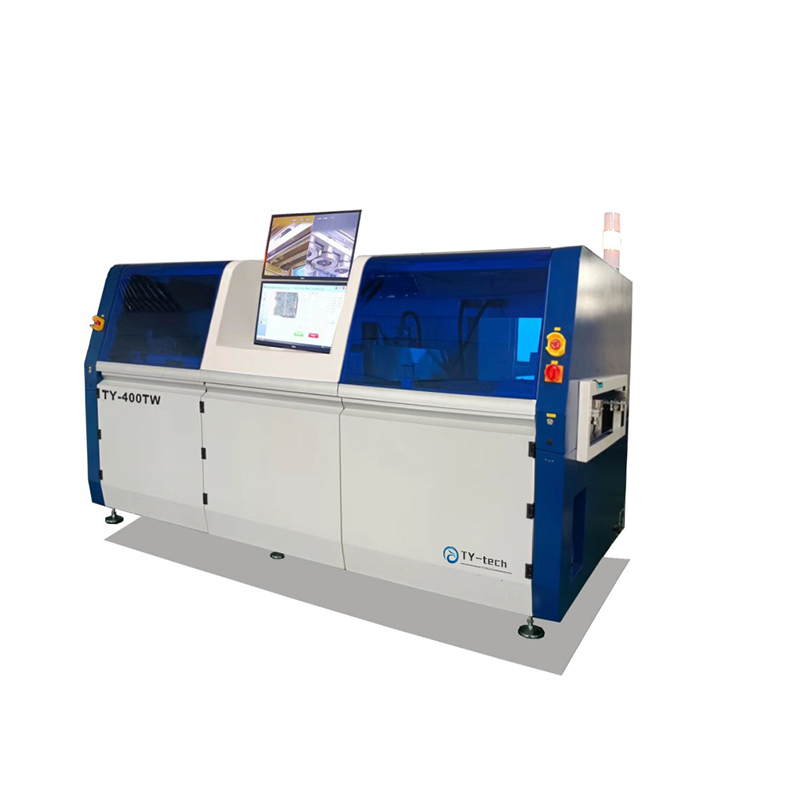

Imininingwane yesithombe

Imininingwane

| Imodeli | TY-400TW-2 |

| Okujwayelekile | |

| Ubukhulu | L3100 * W1650 * H1650mm |

| Amandla ajwayelekile | 28kw |

| Amandla okusebenzisa | 6--10kw |

| Ukunikezwa kwamandla kagesi | Isigaba sesithathu se-five-wire system 380V |

| Isisindo sengqikithi | 350KG |

| Umthombo womoya odingekayo | 3-5 Amabha |

| Ukugeleza komoya okudingekayo | 8-12L/min |

| Ingcindezi ye-N2 edingekayo | 3-4 Amabha |

| Ukugeleza kwe-N2 okudingekayo | >4 cubic metres/ihora |

| Kudingeka ubumsulwa be-N2 | 》99.998% |

| Ukukhathala okudingekayo | Ngaphezulu kwesifutho: 800---1000cbm/h Ngaphezulu kwesithando somlilo: 600---800cbm/h |

| Cinethiwekhi noma i-PCB | |

| Inkampani yenethiwekhi | Kudingeka |

| Ubukhulu besayizi ye-PCB | I-L450 * W230MM*2 Qaphela: I-W iyisiqondiso sobubanzi bomshini |

| Usayizi omncane wenkampani yenethiwekhi | I-L450 * W450MM Qaphela: I-W iyisiqondiso sobubanzi bomshini |

| Indawo ye-solder enkulu | I-L500 * W230MM *2 Qaphela: I-W iyisiqondiso sobubanzi bomshini |

| pcb unqenqema | 3mm noma ngaphezulu |

| Colawulayo & conveyor | |

| Ukulawula | PLC + isilawuli |

| Ububanzi be-Conveyor | 300-600MM |

| Uhlobo lwe-Conveyor | I-pin chain conveyor yokuguquguquka nokushisa kuqala, isidlulisi serola sokusoda |

| Ugqinsi lwe-Conveyor | 1----4mm |

| Isiqondiso se-Conveyor | Kwesobunxele kuya kwesokudla |

| Imvume yokudlulisa | 100MM |

| Ukucaciswa kwe-Conveyor phansi | 30MM |

| Umthwalo we-Conveyor | <10kg |

| Isitimela sokuthutha | Isitimela se-aluminium |

| Ubude be-Conveyor | 900+/-30mm |

| Ithebula elinyakazayo(ukuhamba) | |

| I-eksisi yokunyakaza | X, Y |

| Ukulawula ukunyakaza | Ukulawulwa kwe-Servo |

| Ukunemba kwesikhundla | + / - 0.05 mm |

| I-Chassis | ukushisela insimbi |

| Ukuphathwa kwe-Flux | |

| I-flux nozzle | i-jet valve |

| Ukuqina kweNozzle | insimbi engagqwali |

| Umthamo wethangi le-Flux | 1L |

| I-Flux tank | ithangi lokucindezela |

| Shisisa ngaphambili | |

| Indlela yokushisa | ukushisisa kwe-IR okuphezulu nangaphansi |

| Amandla heater | 16kw |

| Izinga lokushisa | 25--240c degree |

| Ithebula elinyakazayo(i-soldering) | |

| I-eksisi yokunyakaza | X, Y, Z |

| Ukulawula ukunyakaza | isilawuli se-servo |

| Imoto enyakazayo | I-Panasonic servo motor |

| Isikulufu sebhola | Hiwin |

| Ukunemba kwesikhundla | + / - 0.05 mm |

| I-Chassis | Insimbi yokushisela |

| Sibhodwe elidala | |

| Inombolo yebhodwe elijwayelekile | 2 |

| Umthamo webhodwe le-solder | 13kg/ibhodwe*2 |

| Ibanga lokushisa le-solder | I-PID |

| Isikhathi sokuncibilika | 60--70 Amaminithi |

| Izinga lokushisa eliphezulu le-solder | 350 ℃ |

| I-heater kagesi | 1.2kw*2 |

| Sumbhobho omdala | |

| Umbhobho ufiphele | eyenziwe ngokwezifiso |

| Okubalulekile | high carbon alloy |

| I-nozzle ejwayelekile | Ukucushwa okujwayelekile: izingcezu ezi-5 / isithando somlilo (ububanzi bangaphakathi 3mm, 4mm, 5mm, 6mm, 8mm) |

| Ukuphathwa kwe-N2 | |

| I-heater engu-N2 | ifakwe standard |

| Ibanga lokushisa le-Nitrogen PID N2 | 0 - 350 ℃ |

| Ukusetshenziswa kwe-N2 | 1-2m3/h/ingqikithi yebhodwe: 4 m3/h |

-

Izindawo Zokushisisa Ezingu-8 Ikhwalithi Ephakeme Yokugeleza Kabusha Soldering O...

-

I-Mirtec 3D Inline SPI Inspection Machine MS-11

-

I-PCBA Cleaning Machine Ye-SMT Machine Line PCB ...

-

I-Hanwha Multi Functional Chip Mounter HM520W

-

I-Wave Soldering Insertion Production Line 2.4M

-

I-Oven ye-Reflow yase-China, i-SMT Reflow Solder...