Isici

1. Ikhompyutha ye-Brand LCD + isistimu yokulawula ehlakaniphile ye-PLC iyamukelwa, ngokunemba okuphezulu kokulawula izinga lokushisa okungu-±1°C (uma ikhompuyutha iphahlazeka kungalindelekile, umsebenzi ongaxhunyiwe ku-inthanethi ungenziwa ngaphandle kokuthikame ukukhiqiza), ukuqinisekisa ukuzinza nokuthembeka kwesistimu yokulawula. ;

2. I-interface yokusebenza ye-Windows7, inamandla futhi kulula ukuyisebenzisa;

3. Ukuvulwa komzimba wesithando somlilo ongaphezulu kusebenzisa imishini ephindwe kabili kagesi ye-jacking ukuqinisekisa ukuphepha nokuthembeka;

4. Ifakwe idivayisi yokuqinisa ibhande le-mesh, izinto zokuhamba zizinzile, azinyakazi, azikho ukuguquguquka, ziqinisekisa ukuthuthwa okubushelelezi kwe-PCB;

5. I-synchronous guide transmission mechanism (ingaxhunywa ku-inthanethi ngomshini wokubeka ozishintshayo) ukuze kuqinisekiswe ukulungiswa okunembile kobubanzi besitimela somhlahlandlela nokuphila kwesevisi ephezulu;(uma uthanda umzila wesitimela)

6. Lawula ngokuzenzakalelayo uhlelo lokuthambisa, olungagcoba ngokuzenzakalelayo uchungechunge lokudlulisela ngokusetha isikhathi sokugcwalisa kanye nenani lokugcwalisa;

7. Zonke izindawo zokushisisa ziyi-PID elawulwa yikhompyutha (izindawo zokushisa zingavulwa ngokuhlukana. Ukushisa kungahlukaniswa ngamazoni ukuze kuncishiswe amandla okuqala);

8. Ukudluliswa kwenethiwekhi/amaketango kuvalwe ngokuphelele iluphu elawulwa yikhompuyutha, engahlangabezana nokukhiqizwa ngesikhathi esisodwa kwezinhlobo ezahlukene zama-PCB;

9. Ngomsindo wephutha kanye nomsebenzi we-alamu wokukhanya;

10. Ifakwe isivikelo sokuvuza ukuze kuqinisekiswe ukuphepha kwabaqhubi nohlelo lokulawula;

11. I-UPS eyakhelwe ngaphakathi kanye nohlelo lokulibaziseka oluzenzakalelayo ukuze kuqinisekiswe ukuthi i-PCB kanye nomshini wokugcwalisa i-solder ngeke wonakaliswe lapho ugesi unqanyulwa noma ushiswa ngokweqile;

12. Yamukela indlela yokushisa ye-HELLER yokushisa komoya oshisayo, umgudu womoya osebenza kahle kakhulu ocindezelwe, ukwandise kakhulu ukugeleza komoya oshisayo ojikelezayo, ukukhuphuka kwezinga lokushisa ngokushesha (cishe imizuzu eyi-10), ukusebenza kahle kwesinxephezelo sokushisa okuphezulu, kanye ne-welding ephezulu yokushisa nokuphulukisa;

13. Indawo yokushisa ifakwe inzwa ezimele ezwa izinga lokushisa ukuze iqaphe futhi inxephezele ibhalansi yezinga lokushisa yendawo ngayinye yokushisa ngesikhathi sangempela;

14. Uhlelo lokusebenza olunokuphathwa kwephasiwedi luvimbela abasebenzi abangahlobene ekuguquleni imingcele yenqubo, futhi ukuphathwa kwerekhodi lokusebenza kungakwazi ukulandelela inqubo yokushintsha imingcele yenqubo, ekulungele ukuthuthukisa ukuphathwa.Ingagcina izilungiselelo zejubane lokushisa elikhona lomsebenzisi kanye nejika lezinga lokushisa ngaphansi kwesilungiselelo, futhi ingashintsha yonke idatha yokuphrinta namajika;

15. Iwindi lokulawula elididiyelwe, ukushintshwa kwekhompyutha, ijika lokuhlola, ijika lokuphrinta kanye nokudluliswa kwedatha konke kulula ukusebenza, futhi umklamo wenziwa umuntu.Ifakwe uhlelo lokuhlola izinga lokushisa lwejika le-inthanethi leziteshi ezintathu, elikwazi ukubona ijika langempela lokushisa lento yokushisela noma kunini (asikho isidingo sokumisa isihloli sejika lokushisa);

16. Uhlelo lokupholisa olusheshayo oluvela kubuchwepheshe bamazwe ngamazwe lisebenzisa ukupholisa ingilazi ekhulisayo endaweni eyodwa futhi ephumelelayo esheshayo, isivinini sokupholisa singafinyelela ku-3.5~6°C/sec, futhi ukuphatha kulula kakhulu;idivayisi yokupholisa ephoqelekile yangaphandle iqinisekisa umphumela we-crystallization wamalunga e-solder (Inketho yokuzikhethela, ukucushwa okujwayelekile kuphoqeleka ukupholisa umoya wemvelo);

17. Uhlelo lokubuyisela i-rosin: I-rosin igeleza ngendlela eqondile, elula kakhulu ukushintshwa nokuhlanza.Amapayipi akhethekile asetshenziselwa ukudlulisa igesi ephumayo, engakhathalelwa impilo yonke;

18. Isakhiwo esikhethekile sezokuthutha komoya esicindezelwe kanye nomklamo wezintambo zokufudumeza ezimise okukhethekile, akukho msindo, akukho ukudlidliza, izinga lokushisa eliphezulu lokushintshaniswa kokushisa, umehluko wokushisa △t phakathi kokuphansi kwe-BGA nebhodi le-PCB lincane kakhulu, elihlangabezana kangcono kakhulu nemithetho eqinile. izimfuneko zenqubo yokungenamthofu , ikakhulukazi emikhiqizweni engenamthofu enezidingo zokusoda ezinobunzima obukhulu.

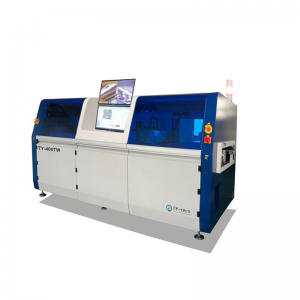

Imininingwane yesithombe

Imininingwane

| Imodeli | I-TYtech 6010 | |

| Isistimu Yokushisa | Inombolo yezindawo zokushisisa | PHEZULU 6/PHANSI 6 |

| Inombolo yezindawo zokupholisa | Phezulu 1/BOTTOM 1 | |

| Ubude bezindawo zokushisisa | 2500MM | |

| Imodi yokushisa | umoya oshisayo | |

| Imodi Yokupholisa | Phoqelela umoya | |

| I-Conveyor System | Ubukhulu.Ububanzi be-PCB | 300mm |

| Ububanzi bebhande lemeshi | 400mm | |

| Transmission Direction | L→R(noma R→L) | |

| Ukuphakama KweNet | 880±20mm | |

| Uhlobo lokudlulisela | I-Mesh neketanga | |

| Ibanga lobubanzi besitimela | 0-300mm | |

| Isivinini se-Conveyor | 0-1500mm/min | |

| Ubude bengxenye | Phezulu 35mm, phansi 25mm | |

| Auto/manual Lubrication | ejwayelekile | |

| Indlela ye-hood ephezulu | I-auto electric hood | |

| Uhlangothi lwesitimela olungaguquki | Isitimela sangaphambili silungisiwe(inketho: isitimela sangemuva silungisiwe) | |

| Izingxenye ziphezulu | Phezulu nangaphansi 25mm | |

| Isistimu yokulawula | Ukunikezwa kwamandla kagesi | 5line 3 isigaba 380V 50/60Hz |

| Amandla okuqalisa | 18kw | |

| Ukusetshenziswa kwamandla okuvamile | 4-7KW | |

| Isikhathi sokufudumala | Cishe imizuzu engama-20 | |

| Temp.ibanga lokusetha | Ukushisa kwegumbi -300 ℃ | |

| Temp.indlela yokulawula | I-PLC ne-PC | |

| Temp.lawula ukunemba | ±1℃ | |

| Temp.ukuchezuka ku-PCB | ±2℃ | |

| Ukugcinwa kwedatha | Cubungula idatha nesimo sokugcina(80GB) | |

| Ipuleti le-nozzle | I-Aluminium Alloy Plate | |

| I-alamu engavamile | Izinga lokushisa elingavamile.(ithempelesha eliphezulu kakhulu/eliphansi ngokwengeziwe.) | |

| Ibhodi lehlise i-alamu | Isibani sombhoshongo: Ukufudumala okuphuzi, okuluhlaza okwejwayelekile, okubomvu-okungavamile | |

| Okujwayelekile | Ubukhulu(L*W*H) | 3600×1100×1490mm |

| Isisindo | 900KG | |

| Umbala | Ikhompyutha empunga | |

-

Umshini Wokuhlanza Izitezi zikagesi TY-800

-

I-PCB Productionn Line SMT PCB Link Conveyor

-

I-Mirtec MV 6 OMNI 3D Inline AOI Umshini Wokuhlola

-

6 Izindawo Zokushisisa Umoya Oshisayo we-SMT Uphinda Ugcwale Ihhavini Yeled...

-

Umshini Wokuhlola I-Stencil Ozenzakalelayo TY-SI80

-

I-SMT Double Head Online PCB Selective Wave Solde...